Muda

無駄·muda·"waste, futility"

Personalize This

Get insights for your role

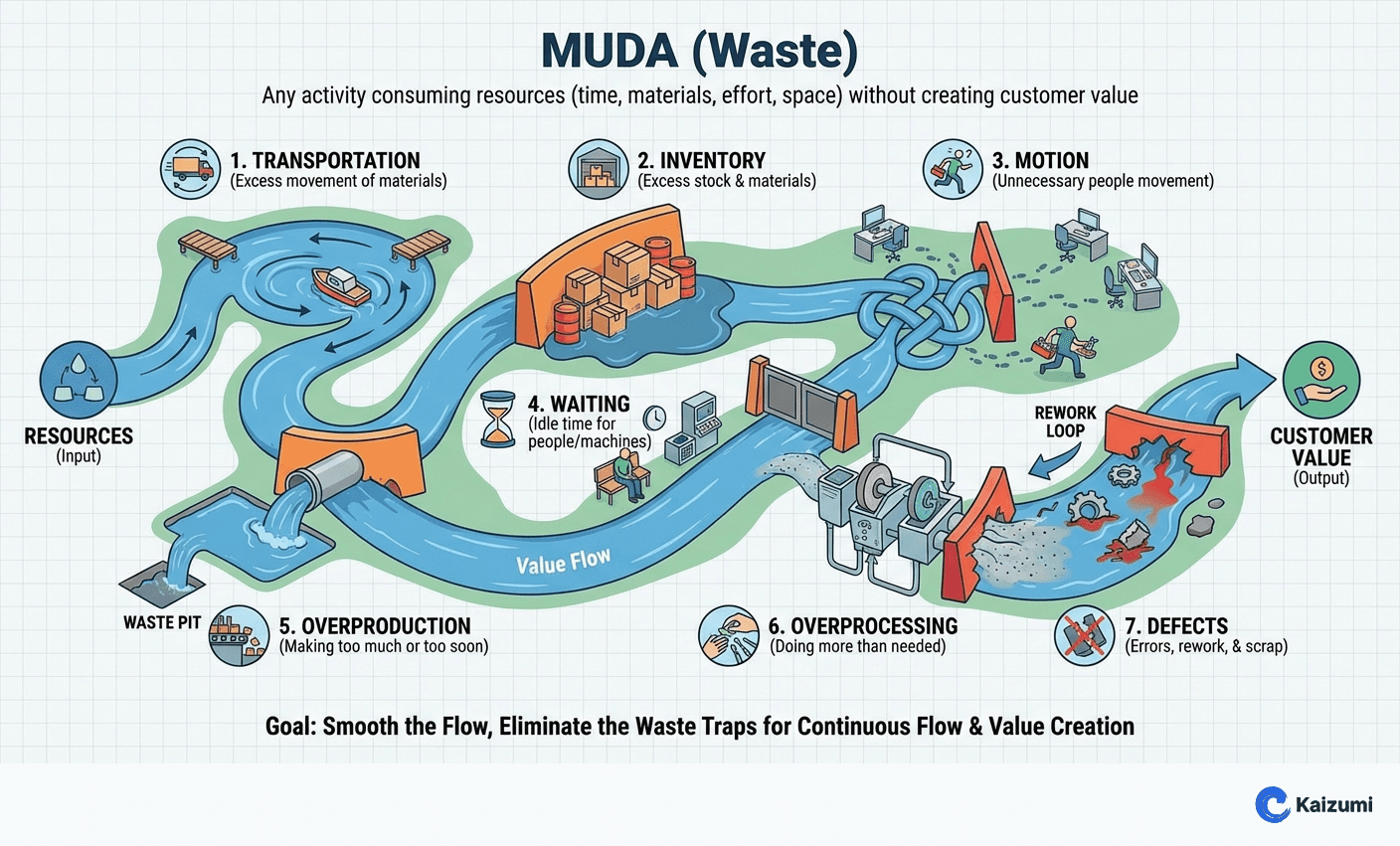

Muda refers to waste in any process - activities that consume resources without creating value for the customer.

Definition

Muda is the Japanese term for waste—any activity that consumes resources (time, materials, effort, space) without creating value from the customer's perspective. In lean thinking, muda is categorized into seven types: transportation, inventory, motion, waiting, overproduction, overprocessing, and defects. Some practitioners add an eighth waste: unused human potential. Identifying and eliminating muda is fundamental to lean improvement, as it frees resources to focus on value-creating activities.

Examples

A value stream mapping exercise revealed that parts traveled 1,200 feet through a factory before assembly, crossing the same aisle four times. This transportation muda added no value but consumed time and created opportunities for damage. Rearranging the layout reduced travel to 200 feet and cut lead time by two days.

Key Points

- The seven wastes provide a framework for systematically identifying non-value-added activities

- Overproduction is often considered the worst waste because it triggers all other wastes

- Some muda is necessary (Type 1) even though it doesn't add value—like regulatory compliance activities

- Eliminating muda requires understanding what customers actually value

Common Misconceptions

All non-value-added activity is waste that should be eliminated. Some activities don't directly create customer value but are necessary—safety checks, regulatory compliance, equipment maintenance. These are Type 1 muda, distinct from Type 2 muda which can be immediately eliminated.

Reducing headcount is the goal of eliminating muda. Lean organizations redeploy freed capacity to growth, quality improvement, or new value creation rather than simply reducing staff. Layoffs following improvement efforts destroy trust and future improvement potential.