PDSA

Personalize This

Get insights for your role

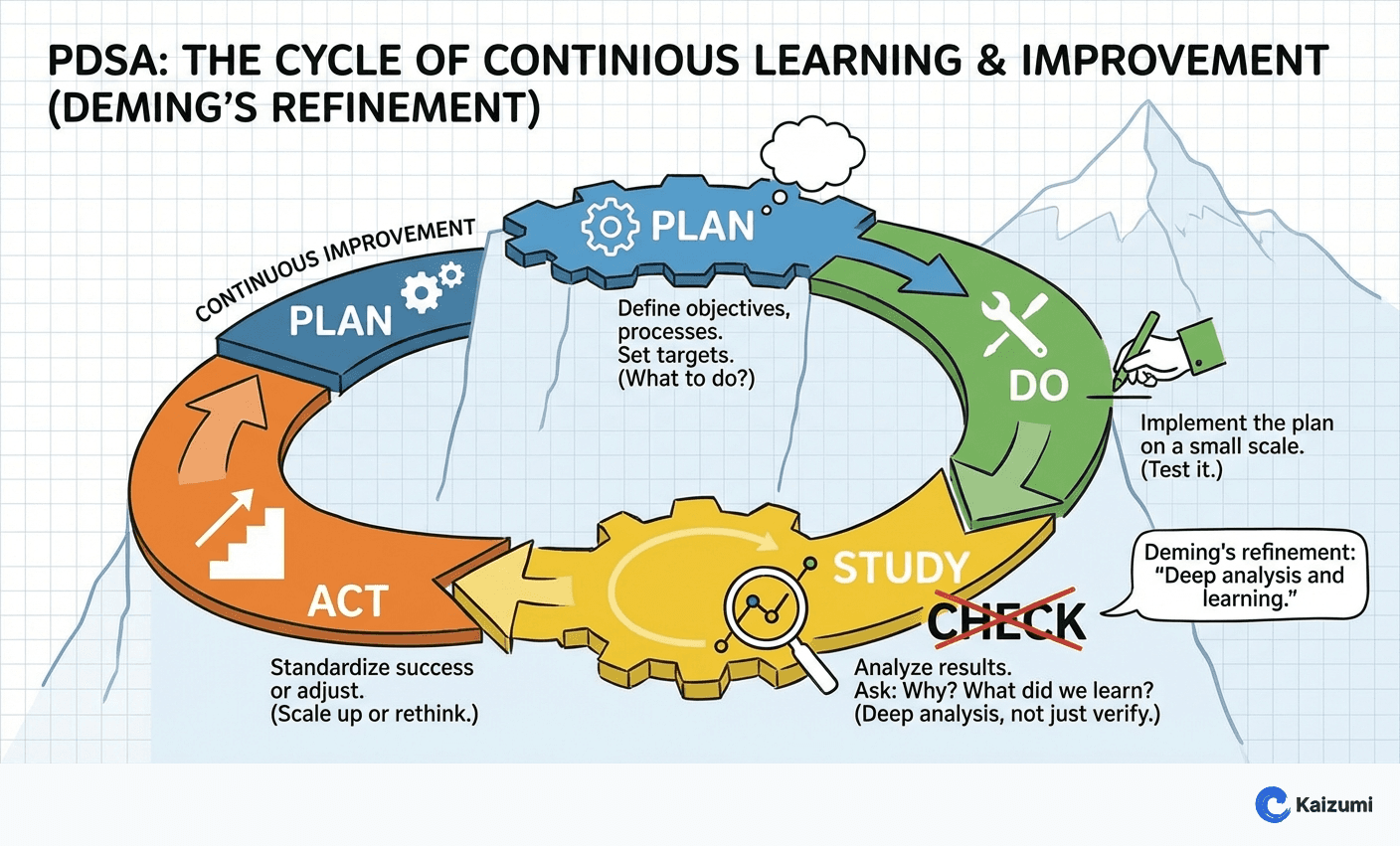

PDSA (Plan-Do-Study-Act) is Deming's refined improvement cycle emphasizing studying results to understand why, not just what happened.

Definition

PDSA (Plan-Do-Study-Act) is W. Edwards Deming's refinement of the PDCA cycle. Deming changed "Check" to "Study" to emphasize that the third phase should involve deep analysis and learning, not just verifying whether results met targets. Study asks: Why did we get these results? What did we learn? How does this change our understanding? This distinction matters because checking only confirms outcomes while studying builds knowledge that informs future cycles and transfers to other situations.

Examples

A PDSA cycle tested a new assembly sequence. Plan predicted 10% time reduction. Do implemented the change. Study analyzed results: actual reduction was 15%—better than predicted. The team studied why, discovering an unexpected benefit from reduced part handling. This learning applied to other assemblies.

Key Points

- "Study" emphasizes learning and understanding, not just measurement

- Study asks "why did this happen?" not just "did it work?"

- Deep study creates transferable knowledge beyond the immediate experiment

- Deming considered the distinction important enough to rename the cycle

Common Misconceptions

PDSA and PDCA are the same thing. The terminology reflects different emphases. PDCA's "Check" risks becoming a simple yes/no evaluation. PDSA's "Study" demands deeper analysis of mechanisms and meaning.

Study just means more measurement. Study is qualitative analysis and reflection, not just more data. It asks why results occurred and what they mean for future understanding.