Process Capability

Personalize This

Get insights for your role

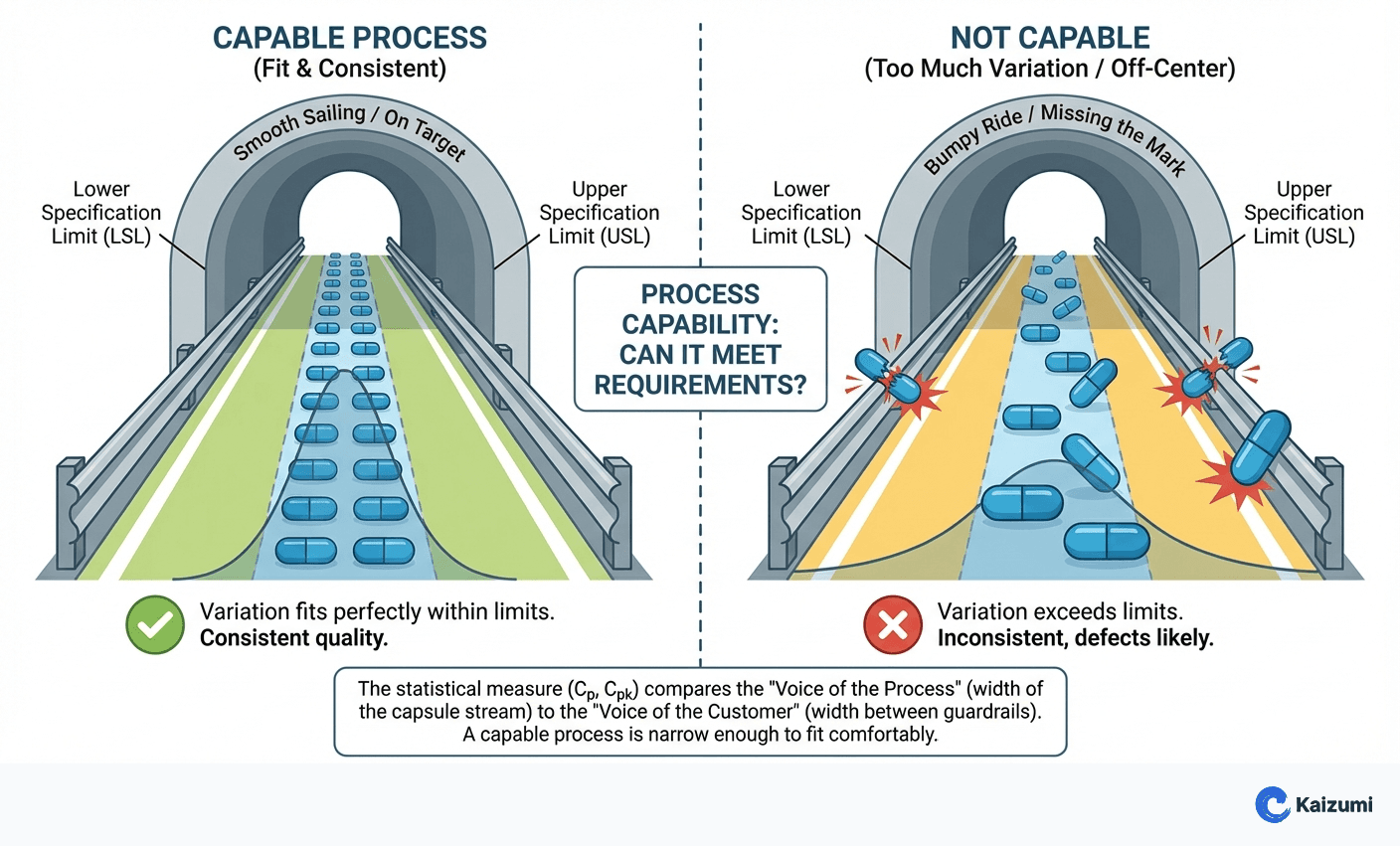

Process capability measures how well a process meets specification requirements, comparing natural process variation to allowable tolerance.

Definition

Process capability is a statistical measure comparing a process's natural variation to customer specification limits. It answers the question: "Can this process consistently produce output within requirements?" A capable process has variation narrow enough to fit well within specification limits with margin to spare. Process capability is typically expressed through indices like Cp (potential capability) and Cpk (actual capability accounting for centering). A Cpk of 1.33 or higher is generally considered capable; 2.0 or higher represents Six Sigma performance.

Examples

A machining process produces shafts with specification 50.0 ± 0.5 mm. Statistical analysis shows the process mean is 50.1 mm with standard deviation of 0.12 mm. Cpk = (50.5 - 50.1) ÷ (3 × 0.12) = 1.11. This indicates marginal capability—some defects are likely. The team works to reduce variation or recenter the process.

Key Points

- Cp measures potential capability (variation width vs. tolerance width)

- Cpk measures actual capability (accounts for process centering)

- Cpk ≥ 1.33 is typically considered "capable" for existing processes

- Cpk ≥ 1.67 is often required for new processes or critical characteristics

Common Misconceptions

A Cp of 1.0 means 100% of output meets spec. A Cp of 1.0 means the process spread exactly equals the tolerance width—even perfectly centered, approximately 0.27% of output (2,700 ppm) falls outside specifications. Capable processes need Cp > 1.0 for margin.

High Cp guarantees low defects. Cp measures potential capability assuming perfect centering. If the process mean drifts toward a specification limit, actual defect rates increase dramatically. Cpk is the relevant measure for actual performance.