Seiketsu (Standardize)

清潔·seiketsu·"cleanliness, purity"

Personalize This

Get insights for your role

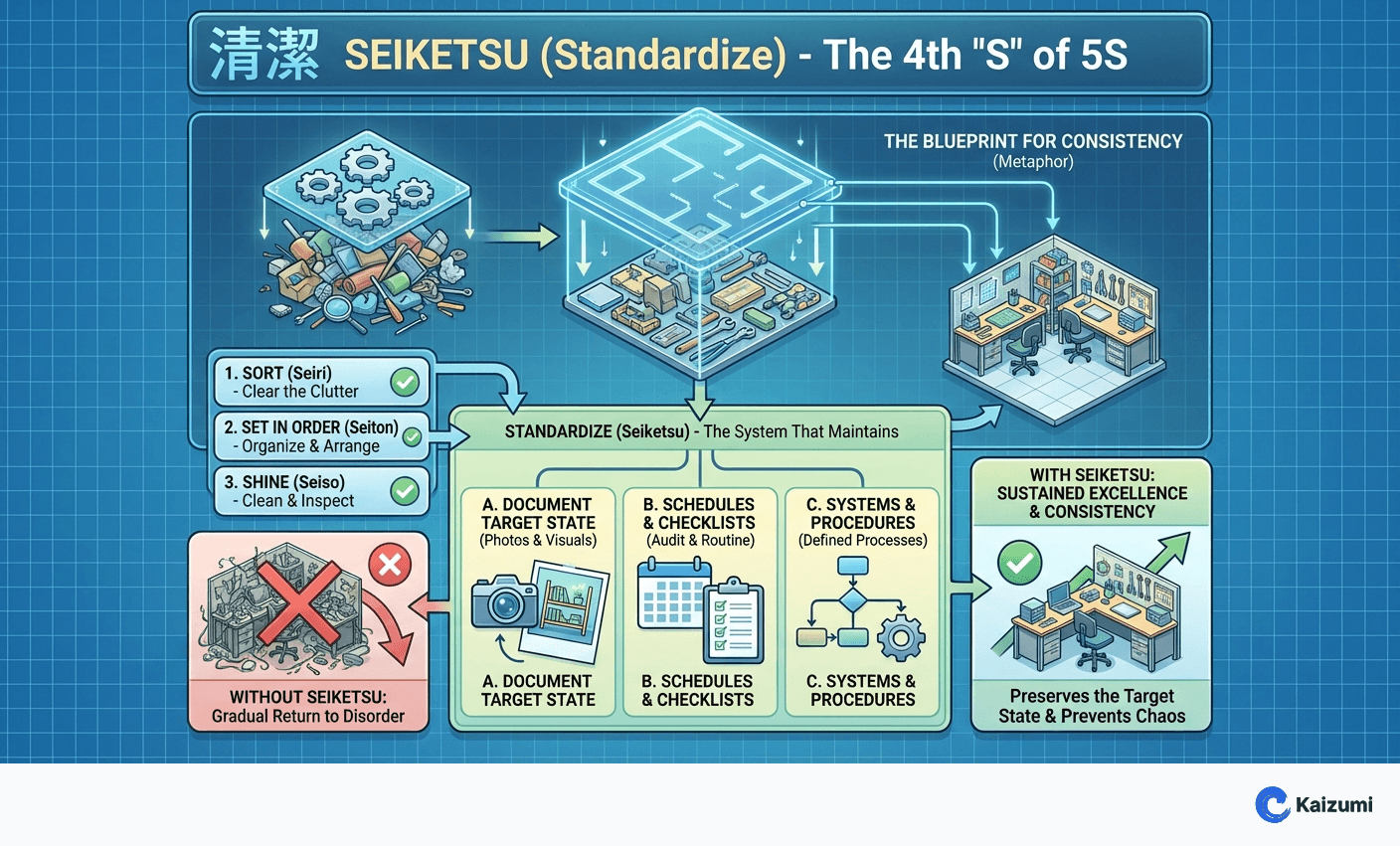

Seiketsu is the fourth of the 5S steps - creating standards and systems to maintain Sort, Set in Order, and Shine.

Definition

Seiketsu, meaning "Standardize," is the fourth step of the 5S methodology. It creates the standards, schedules, and systems that maintain the first three S's (Sort, Set in Order, Shine). Without seiketsu, workplaces gradually return to disorder. Seiketsu documents the target state (photos of how areas should look), assigns responsibilities (who cleans what when), establishes schedules (daily, weekly, monthly tasks), and creates visual controls that make the standard condition obvious. Seiketsu converts one-time cleanup into sustainable practice.

Examples

After initial 5S implementation, seiketsu created standard work for daily cleanup (assigned tasks at shift end), weekly deep cleaning (rotating areas), and monthly audits (checklist with scoring). Photos of correct conditions were posted at each workstation for reference.

Key Points

- Seiketsu prevents the gradual decay that follows one-time 5S events

- Visual standards (photos, labels) make correct conditions obvious

- Assigned responsibilities ensure tasks don't fall through cracks

- Schedules convert occasional cleanup into routine discipline

Common Misconceptions

Seiketsu is just documentation. Documentation supports standardization but isn't the goal. Seiketsu creates the systems, assignments, and visual controls that make the first three S's sustainable.

Once standardized, 5S is complete. Standards need enforcement and improvement. Seiketsu creates the structure, but shitsuke (sustain) ensures it's actually followed, and continuous improvement refines the standards.