Throughput

Personalize This

Get insights for your role

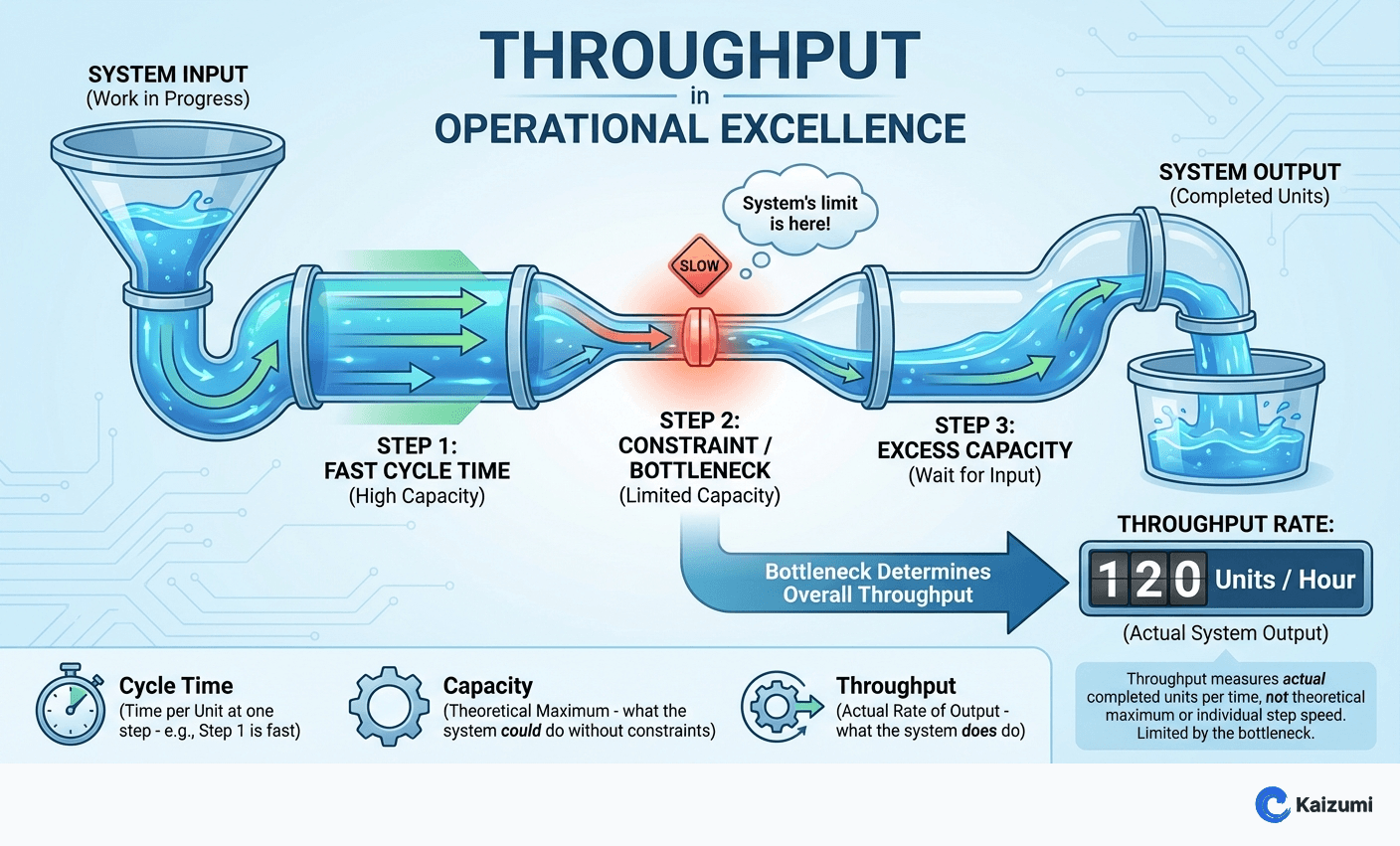

Throughput is the rate at which a system produces finished goods or services - the output over a given time period.

Definition

Throughput is the rate at which a system generates output—the number of units completed per unit of time. Unlike cycle time (time per unit at one step) or capacity (theoretical maximum), throughput measures actual system output. Throughput is ultimately limited by the system's constraint or bottleneck; improving non-constraint processes doesn't improve throughput. In Theory of Constraints, throughput is defined more specifically as the rate at which the system generates money through sales, emphasizing that only sold output counts.

Examples

A production line has 10 workstations. Each station's cycle time is under 1 minute, suggesting capacity of 60+ units per hour. But actual throughput is 45 units per hour because one station with reliability problems limits the whole line. Throughput equals the rate of the constraint.

Key Points

- Throughput measures actual output, not theoretical capacity

- System throughput is determined by the constraint—the slowest or most limiting element

- Improving non-constraints doesn't improve system throughput

- Throughput is the primary measure in Theory of Constraints

Common Misconceptions

Higher throughput is always better. Throughput should match demand, not maximize capacity. Producing faster than demand creates overproduction waste. The goal is appropriate throughput to meet customer needs.

Improving any step improves throughput. Only improvements at the constraint improve system throughput. Improvements elsewhere create local efficiency without system benefit—possibly even creating more work-in-process.