Toyota Way

Personalize This

Get insights for your role

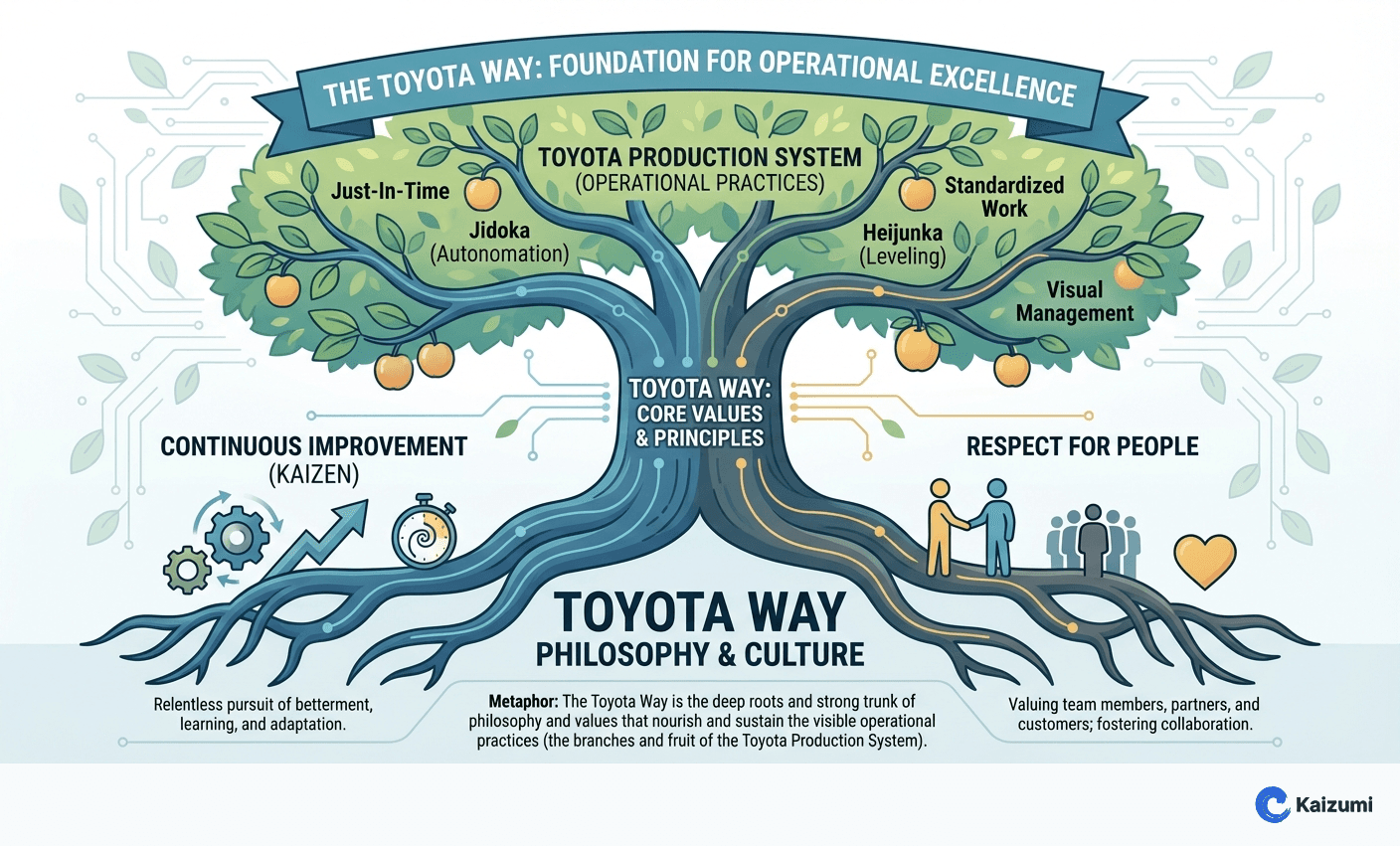

The Toyota Way is Toyota's management philosophy built on two pillars: continuous improvement and respect for people.

Definition

The Toyota Way is Toyota's management philosophy and culture, articulated as two core pillars: Continuous Improvement (kaizen) and Respect for People. While the Toyota Production System describes the operational practices, the Toyota Way describes the underlying management principles and values that make TPS sustainable. The Toyota Way includes 14 management principles organized into four categories: long-term philosophy, the right process producing right results, adding value by developing people, and continuous learning through problem-solving.

Examples

When Toyota faced a sudden quality crisis with unintended acceleration concerns, the Toyota Way guided their response. Rather than defensiveness, they practiced genchi genbutsu (going to see), hansei (reflection), and open problem-solving. They expanded quality reviews, improved response processes, and emerged with even stronger systems—demonstrating how the Toyota Way handles adversity.

Key Points

- The Toyota Way is the "why" behind the "what" of the Toyota Production System

- Neither pillar works without the other—improvement requires engaged people; respect requires supporting improvement

- Long-term thinking is essential; the Toyota Way explicitly rejects short-term financial optimization

- Culture change is required for sustainable lean transformation

Common Misconceptions

The Toyota Way is just company-specific culture. While developed at Toyota, the principles are applicable universally. Other organizations have successfully adopted the Toyota Way principles, though implementation requires adaptation to their context.

Adopting tools is the same as adopting the Toyota Way. Tools without the underlying philosophy produce disappointing, unsustainable results. The Toyota Way is primarily about how managers think and behave, not which tools they deploy.