Work Sampling

Personalize This

Get insights for your role

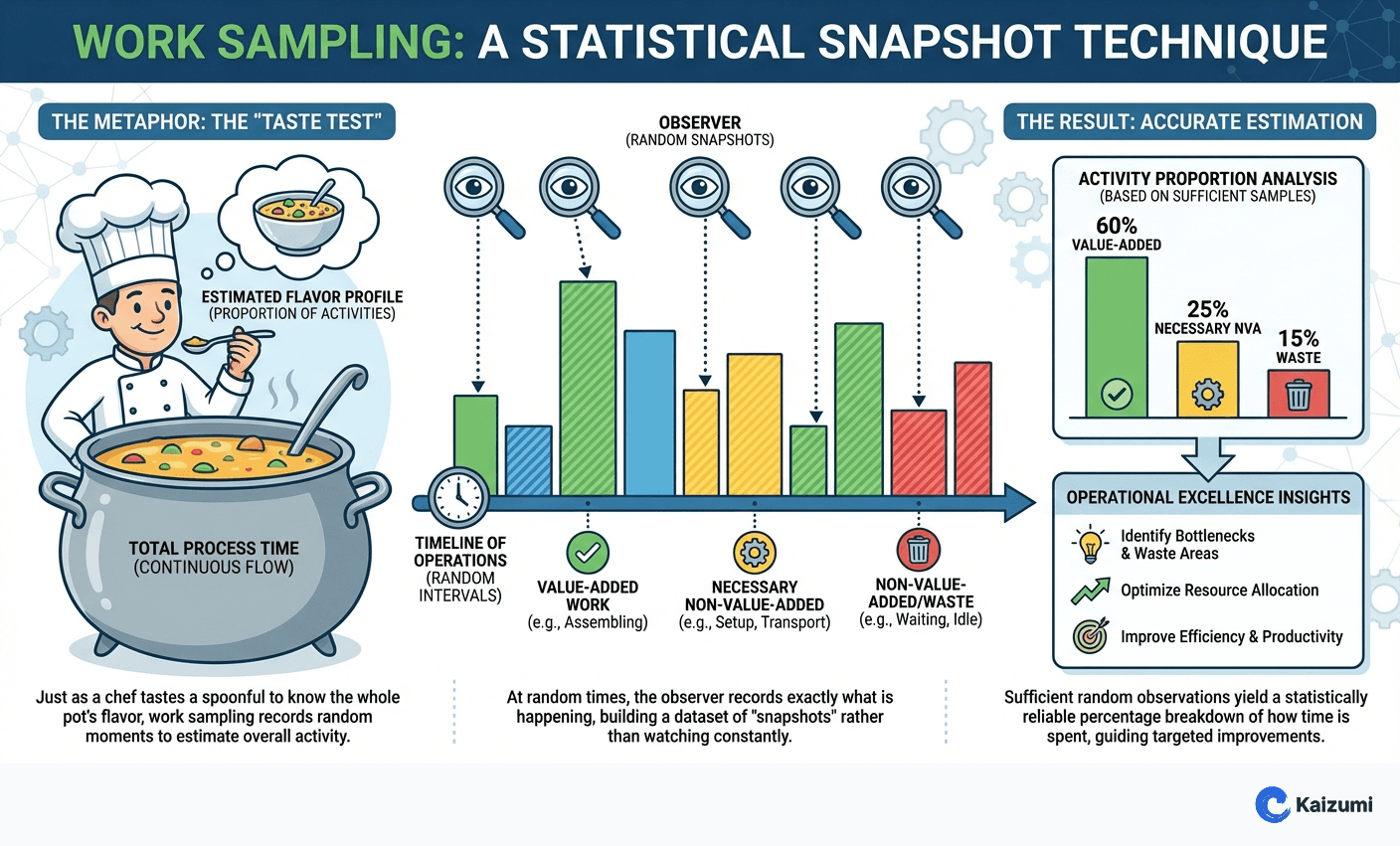

Work sampling estimates time proportions spent on activities through random observations rather than continuous measurement.

Definition

Work sampling is a statistical technique that estimates the proportion of time spent on different activities through random observations rather than continuous measurement. At random intervals, an observer records what activity is occurring at that moment. With sufficient observations, the percentages accurately reflect actual time allocation. Work sampling is less intrusive than continuous time study, can cover multiple workers simultaneously, and efficiently reveals how time is divided between value-adding work, necessary non-value-adding activities, and waste.

Examples

Work sampling across 400 random observations of machine operators revealed: 45% operating machines, 20% setup and changeover, 15% waiting for materials, 10% walking, 10% other. This breakdown identified material delivery and layout as major improvement opportunities without requiring continuous observation.

Key Points

- Random timing of observations is essential for statistical validity

- More observations yield greater accuracy; statistical formulas guide sample size

- Work sampling is less intrusive than continuous observation

- Results show proportions, not absolute times—useful for different purposes than time study

Common Misconceptions

Work sampling replaces time study. Work sampling and time study serve different purposes. Sampling shows how time is proportioned; time study measures how long specific elements take. Both are valuable.

A few observations are enough. Statistical accuracy requires sufficient sample size. Too few observations yield unreliable estimates. Standard formulas determine required sample size for desired accuracy.