Availability

Personalize This

Get insights for your role

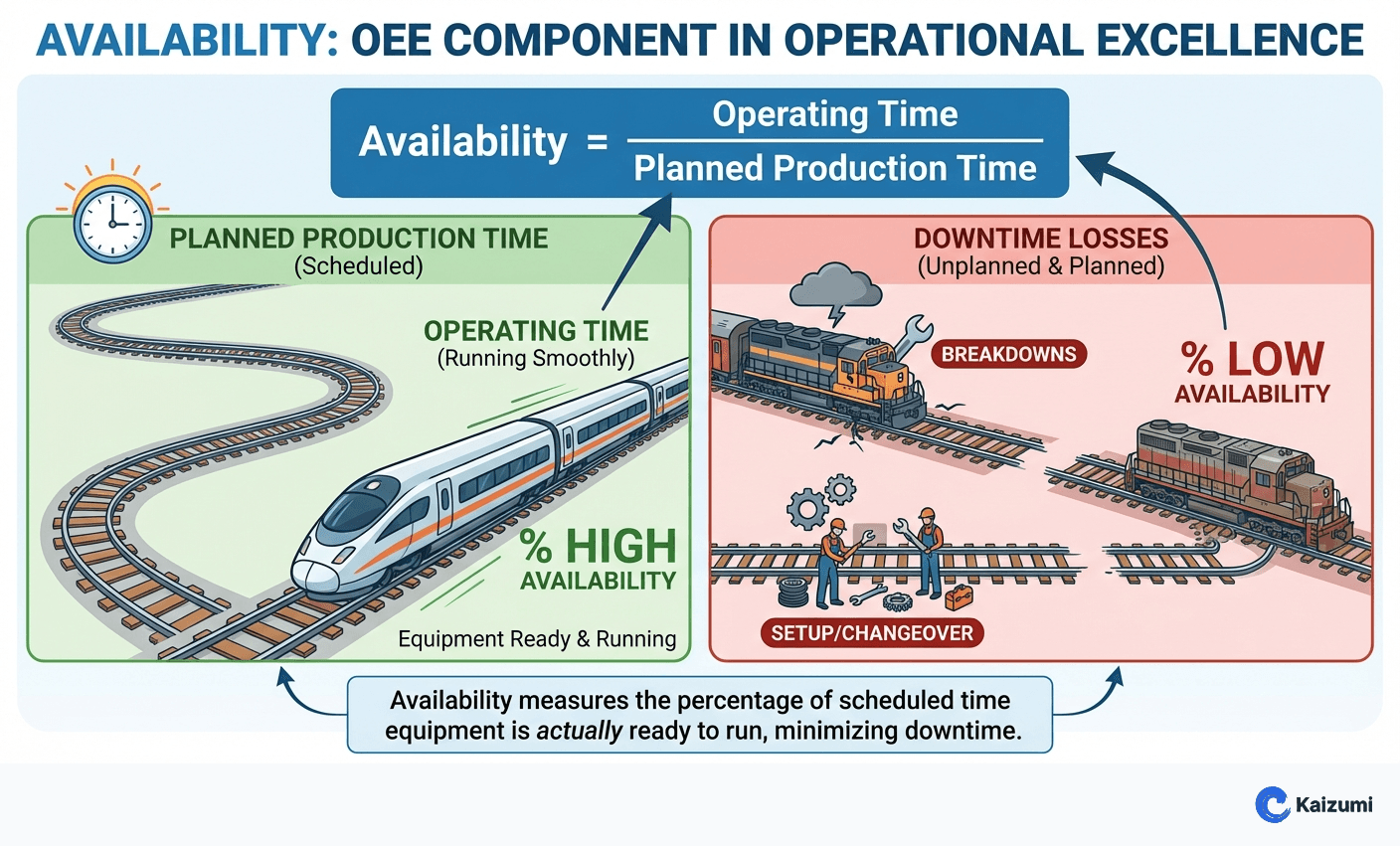

Availability is the percentage of scheduled time that equipment is actually available for production, accounting for downtime from breakdowns and changeovers.

Definition

Availability is a component of OEE that measures the percentage of scheduled production time when equipment is actually available to run. It accounts for downtime losses from equipment breakdowns and setup/changeover time. Availability = Operating Time / Planned Production Time. High availability indicates minimal unplanned stops and efficient changeovers. It is the first factor in the OEE calculation and often the largest opportunity for improvement.

Examples

A shift runs 480 minutes with two 15-minute breaks (450 minutes planned production time). Breakdowns consume 30 minutes; changeovers take 45 minutes. Operating time = 450 - 30 - 45 = 375 minutes. Availability = 375 / 450 = 83.3%.

Key Points

- Availability = Operating Time / Planned Production Time

- Losses include breakdowns and setup/changeover time

- First component of OEE calculation

- MTBF and MTTR directly affect availability: A = MTBF / (MTBF + MTTR)

Common Misconceptions

High availability means the equipment is productive. Equipment can be available (not broken down) but running slowly or producing defects. Availability is necessary but not sufficient for productivity—Performance and Quality also matter.

Scheduled maintenance reduces availability. Properly accounted, planned maintenance reduces planned production time, not operating time. Availability measures unplanned losses and changeovers, not scheduled downtime.