Capacity Constrained Resource

Personalize This

Get insights for your role

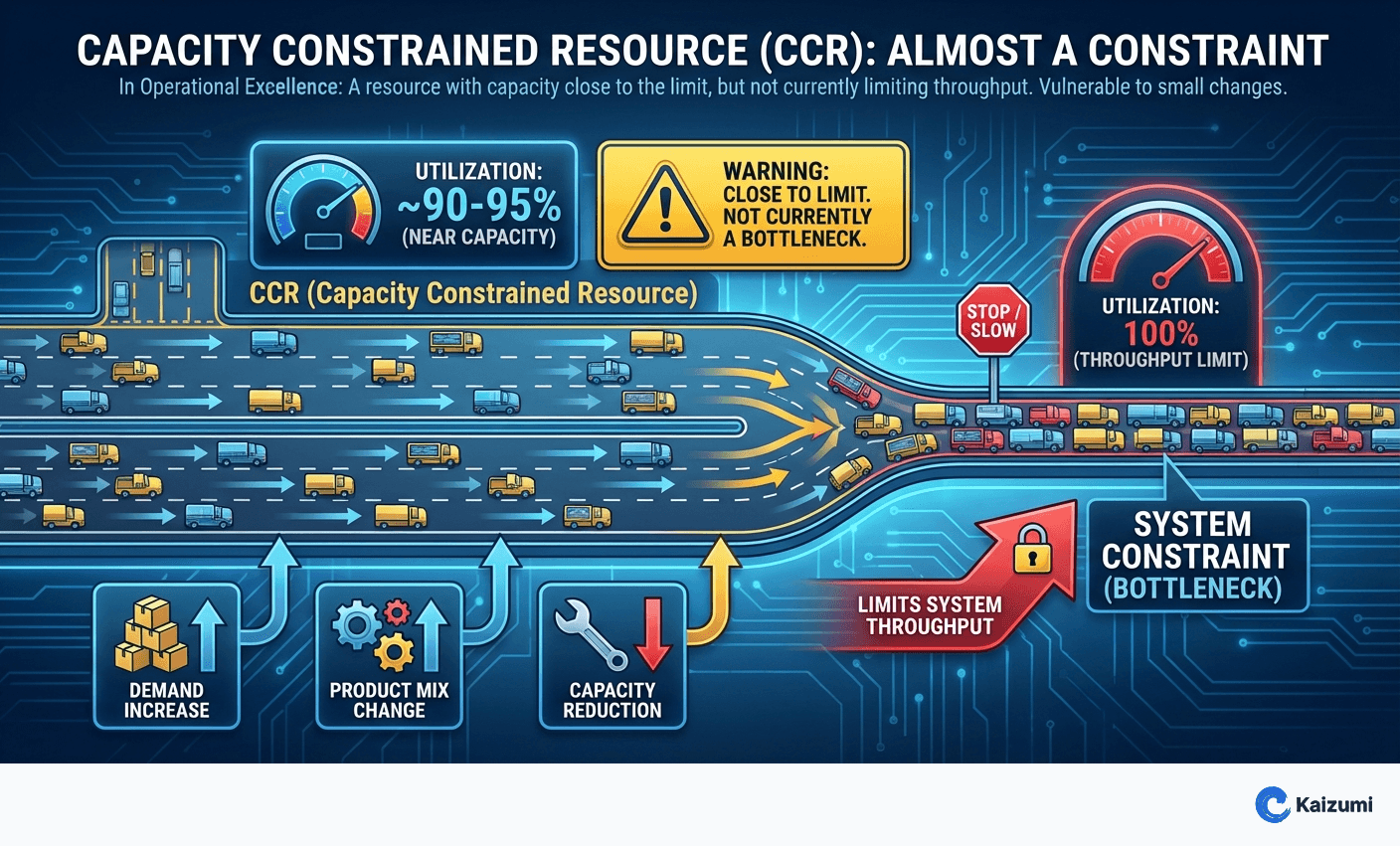

A Capacity Constrained Resource (CCR) is a resource with capacity close to demand that could become the system constraint with small changes.

Definition

A Capacity Constrained Resource (CCR) is a resource with available capacity close to, but not quite at, the level needed to become the system constraint. CCRs don't currently limit throughput, but they could become constraints with small demand increases, product mix changes, or capacity reductions. CCRs require attention because elevating the current constraint might simply shift the constraint to a CCR. DBR systems often place buffers before CCRs to protect against fluctuation-induced starvation.

Examples

A plant's constraint was heat treatment at 95% utilization. Painting ran at 88% utilization—a CCR. When the team proposed adding heat treatment capacity, they recognized that painting would become the new constraint. The investment plan included both resources.

Key Points

- Capacity close to demand but not currently the constraint

- Could become constraint with small changes in demand or capacity

- Important to identify when planning constraint elevation

- May warrant protective buffers in DBR systems

Common Misconceptions

CCRs need the same attention as the constraint. CCRs need monitoring and planning, but not the intensive exploitation and subordination focus of the constraint. Improving a CCR when it's not the constraint doesn't improve system throughput.

Every resource with less than 100% utilization is fine. CCRs may be running well below 100% but still be vulnerable to becoming constraints. The proximity to demand matters more than absolute utilization.