Drum-Buffer-Rope

Personalize This

Get insights for your role

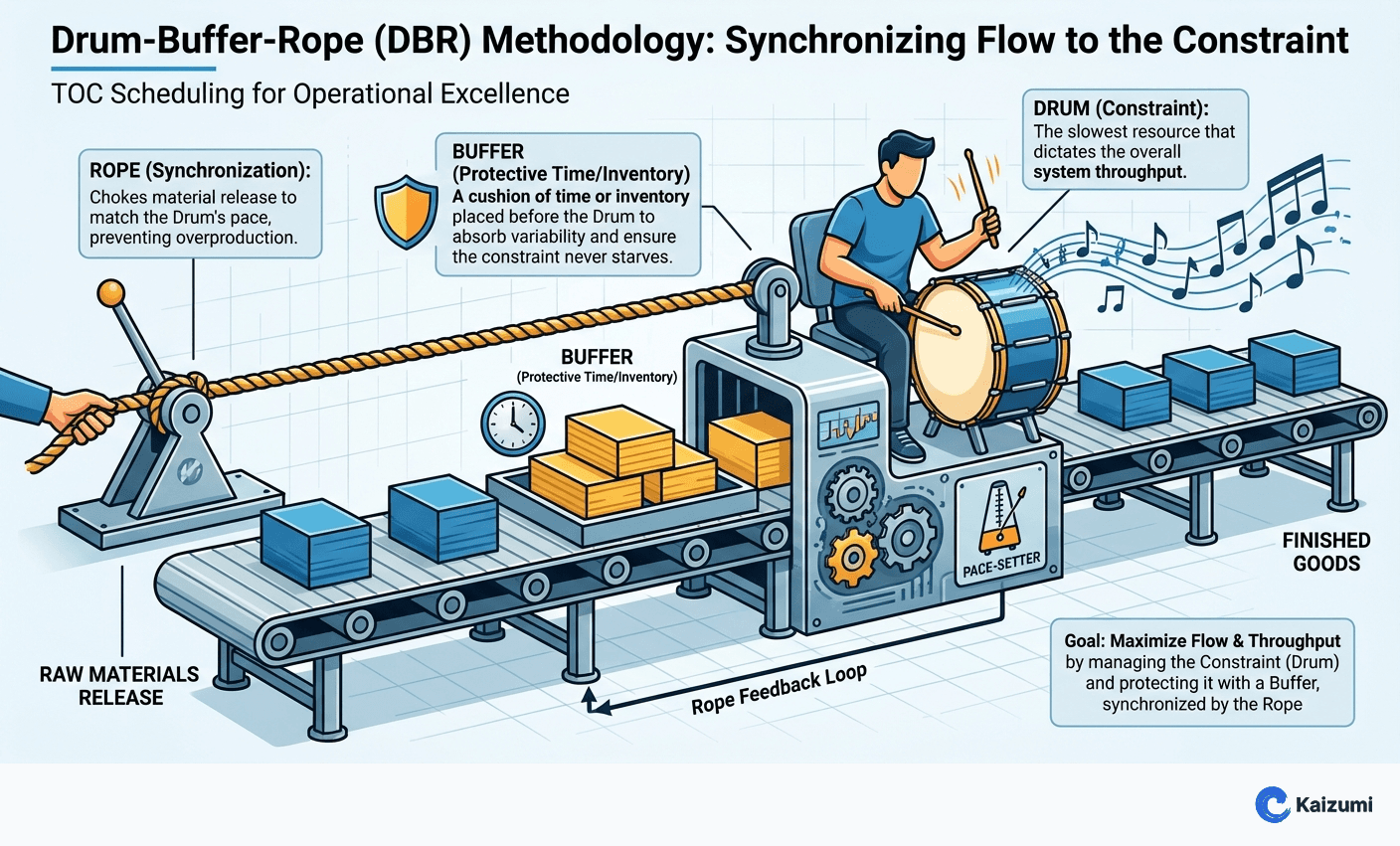

Drum-Buffer-Rope is a TOC scheduling method that synchronizes production to the constraint, protects it with buffers, and controls material release.

Definition

Drum-Buffer-Rope (DBR) is the TOC scheduling methodology that synchronizes production flow to the system constraint. The Drum is the constraint resource, which sets the pace for the entire system—like a drummer keeping time. The Buffer is protective time or inventory placed before the constraint, ensuring it never starves due to upstream variation. The Rope is the communication mechanism that releases material to the first operation, timed to arrive at the constraint when needed. DBR prevents both constraint starvation and excess work-in-process.

Examples

A machine shop identified CNC turning as the constraint. DBR scheduled: CNC capacity (drum) determined daily output targets. A 2-day work buffer accumulated before CNC. Raw material release (rope) was timed so jobs arrived at CNC with 2 days buffer. WIP dropped 40% while throughput held steady.

Key Points

- Drum: Constraint sets the system pace

- Buffer: Time/inventory protecting the constraint from starvation

- Rope: Controls material release to match constraint capacity

- Synchronizes flow without detailed scheduling of non-constraints

Common Misconceptions

DBR requires detailed scheduling of every resource. Only the constraint (drum) needs detailed scheduling. Non-constraints have excess capacity by definition—they can process whenever work arrives. Simplifying non-constraint scheduling is a DBR feature.

Buffers are waste to be eliminated. In DBR, buffers protect throughput by ensuring the constraint never waits. A starved constraint loses throughput forever. Strategic buffers are an investment in throughput protection, not waste.