Early Equipment Management

Personalize This

Get insights for your role

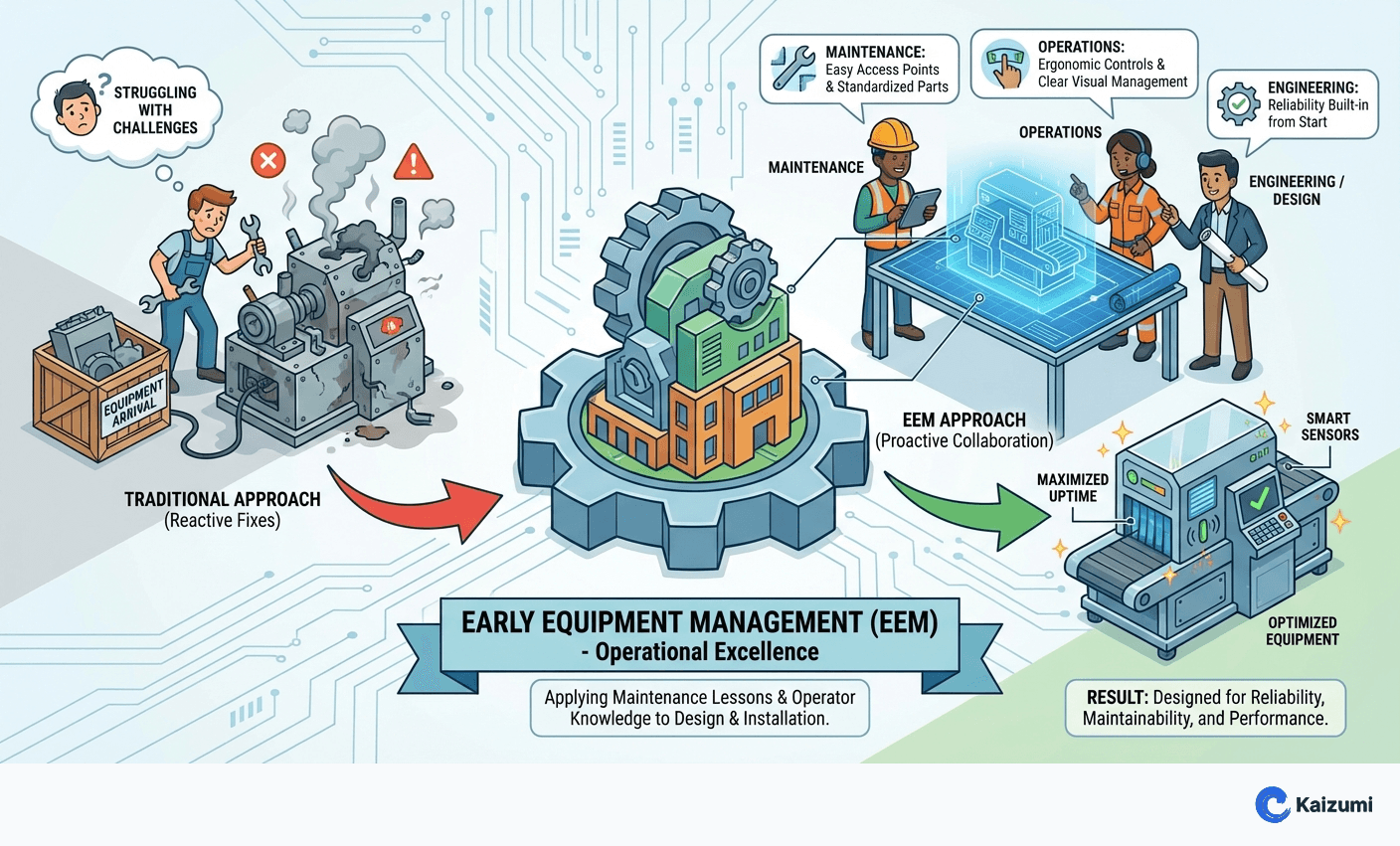

Early equipment management applies TPM lessons learned to new equipment design and installation, building maintainability in from the start.

Definition

Early equipment management (EEM) is the TPM pillar that applies maintenance lessons and operator knowledge to the design and installation of new equipment. Rather than accepting whatever equipment arrives and then struggling with maintenance challenges, EEM involves maintenance and operations in equipment specification, design review, and installation planning. The goal is equipment that is reliable, maintainable, operable, and achieves full productivity quickly—building TPM principles in rather than retrofitting them later.

Examples

Before purchasing new packaging equipment, the TPM team reviewed maintenance records from existing similar machines. Common failure modes informed specification requirements: better bearing access, improved guarding for cleaning, and sensor placement for predictive monitoring. The new equipment reached full OEE three months faster than previous installations.

Key Points

- Applies TPM lessons learned to new equipment before purchase/installation

- Involves maintenance and operations in equipment specification and design

- Goals: reliability, maintainability, operability, rapid startup

- Prevents repeating problems seen in existing equipment

Common Misconceptions

EEM only matters for custom equipment. Even purchased standard equipment benefits from EEM—specification requirements, installation planning, and startup preparation all improve outcomes. Vendor selection criteria can include maintainability factors.

EEM delays equipment acquisition. Proper EEM may extend the specification phase but compresses startup and reduces lifetime maintenance. Total time-to-value typically improves despite longer planning.