Total Productive Maintenance

Personalize This

Get insights for your role

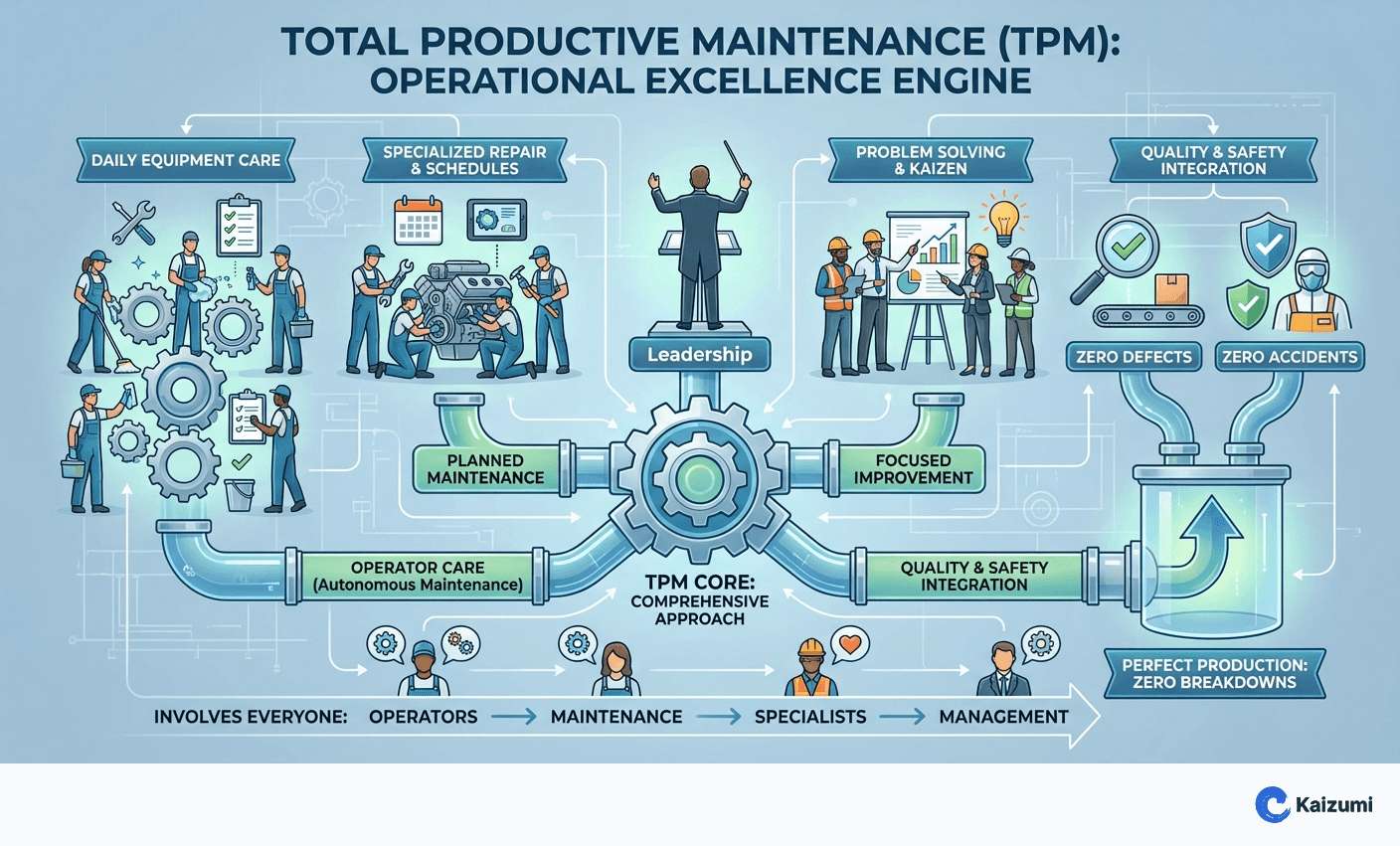

Total Productive Maintenance (TPM) is a holistic approach to equipment maintenance that maximizes equipment effectiveness through operator involvement and proactive care.

Definition

Total Productive Maintenance (TPM) is a comprehensive approach to equipment maintenance that aims to achieve perfect production with no breakdowns, no defects, and no accidents. TPM involves everyone in the organization—from operators who perform daily equipment care to specialized maintenance technicians. The methodology rests on eight pillars: autonomous maintenance, planned maintenance, quality maintenance, focused improvement, early equipment management, training, safety/health/environment, and TPM in administration. TPM treats equipment as a strategic asset requiring holistic care.

Examples

A food processing plant implemented TPM over 18 months. Operators learned to clean, inspect, and lubricate their machines daily. Breakdowns dropped 70%, and OEE improved from 58% to 82%. The investment in operator training and maintenance partnership transformed equipment reliability.

Key Points

- Eight pillars provide comprehensive framework for equipment excellence

- Operators become the first line of defense through autonomous maintenance

- Goal is zero breakdowns, zero defects, zero accidents

- Requires cultural shift from "I operate, you fix" to shared ownership

Common Misconceptions

TPM is just a maintenance program. TPM transforms organization culture around equipment—it involves operators, engineers, managers, and support functions. Treating it as only a maintenance initiative misses the productivity and quality benefits.

TPM means operators do all maintenance. Operators handle cleaning, inspection, and basic tasks through autonomous maintenance. Skilled maintenance technicians remain essential for complex repairs, predictive maintenance, and technical improvements. TPM creates partnership, not replacement.