Measurement System Analysis

Personalize This

Get insights for your role

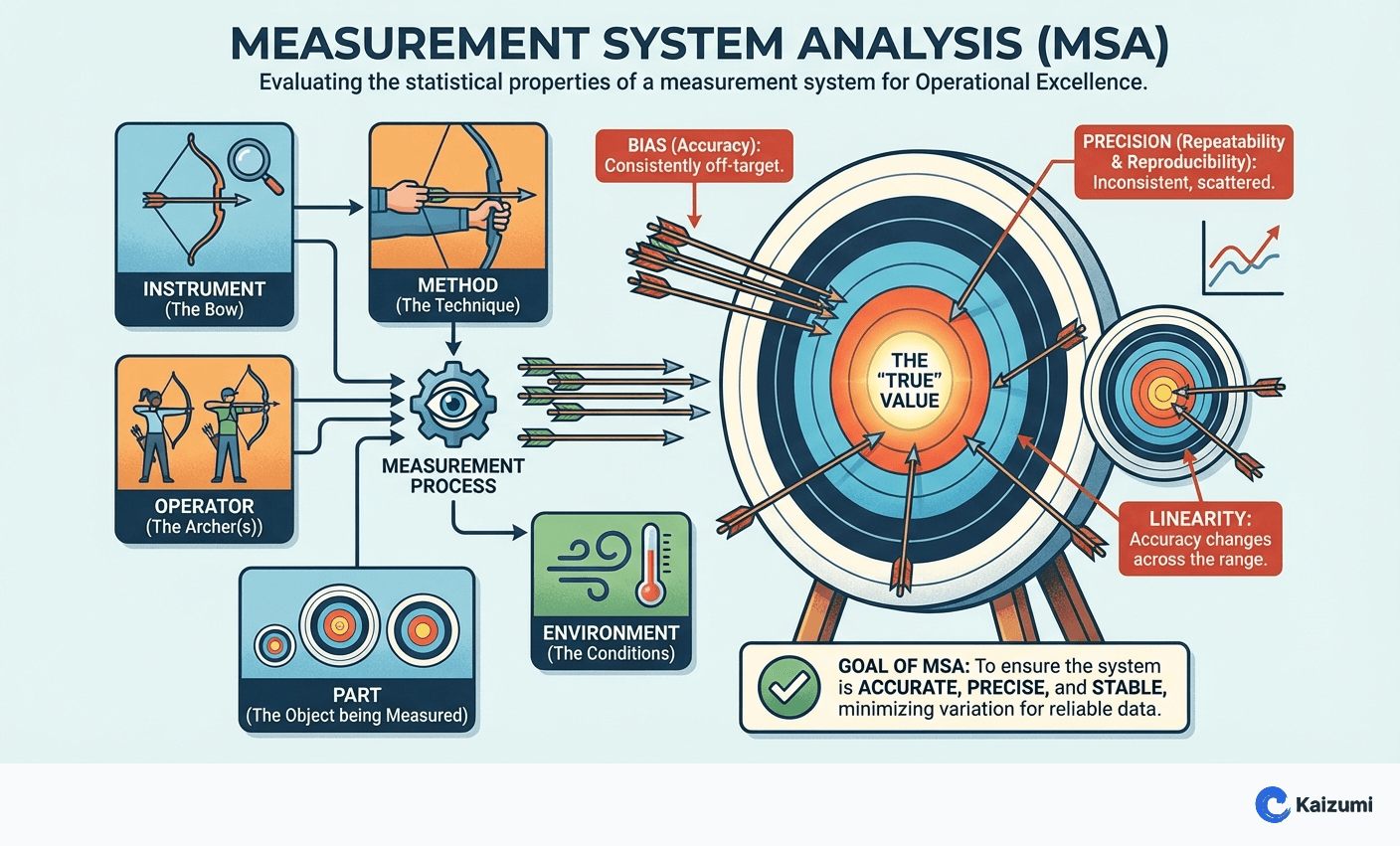

Measurement System Analysis (MSA) is a collection of methods for evaluating whether a measurement system provides reliable, accurate data for decision-making.

Definition

Measurement System Analysis (MSA) is a collection of experiments and methods that evaluate the statistical properties of a measurement system. A measurement system includes the instrument, the method, the operator, the environment, and the part being measured. MSA quantifies bias (accuracy), linearity (bias across the measurement range), stability (bias over time), and precision (repeatability and reproducibility). Poor measurement systems add variation that masks true process behavior—MSA ensures data quality before using data for analysis.

Examples

Before a variation reduction project, MSA revealed the measurement system contributed 45% of observed variation. Most came from reproducibility—different inspectors measured differently. The team standardized measurement technique before collecting process data, ensuring the data would reflect true process variation.

Key Points

- Five key properties: accuracy, linearity, stability, repeatability, reproducibility

- Conduct MSA before using data for process analysis or improvement

- Target: measurement system contributes <10% of total variation

- Different studies address different properties (bias studies, Gage R&R)

Common Misconceptions

Calibrated equipment means the measurement system is good. Calibration addresses instrument accuracy but not operator technique, environmental factors, or method variation. A calibrated gauge with inconsistent operators still produces unreliable data.

MSA is only for physical measurements. Any judgment or assessment benefits from MSA—quality ratings, inspection decisions, subjective evaluations. If different people might get different results measuring the same thing, MSA applies.