Mistake-Proofing

Personalize This

Get insights for your role

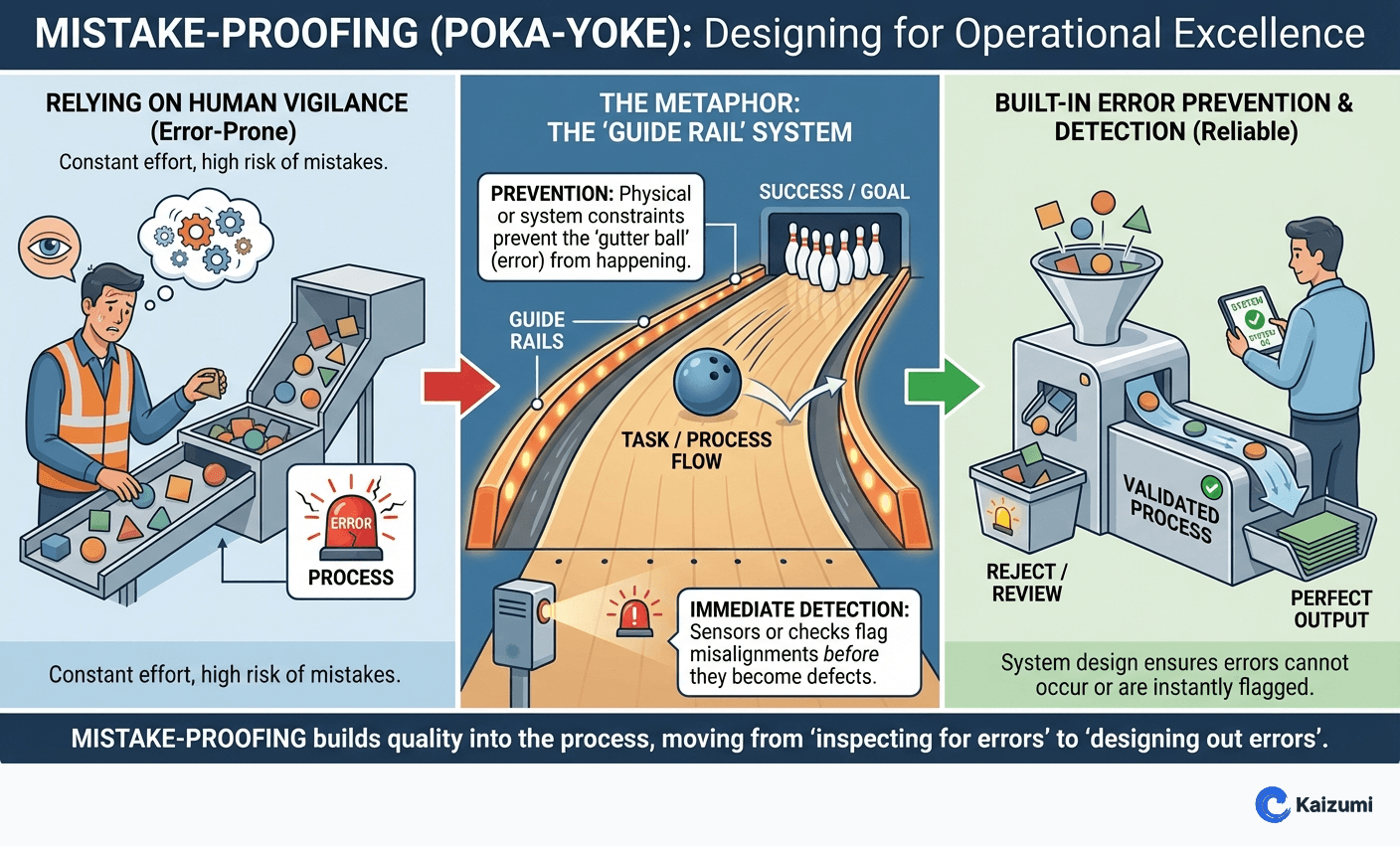

Mistake-proofing is designing processes and devices to prevent human errors or make them immediately detectable.

Definition

Mistake-proofing (the English translation of poka-yoke) is the practice of designing processes, equipment, and systems so that errors either cannot occur or are immediately detected when they do. Rather than relying on human attention and effort to avoid mistakes, mistake-proofing builds error prevention into the design. There are three levels: prevention (error is impossible), detection (error is caught before impact), and warning (error is signaled when it occurs). Prevention is most effective; warnings are least but still valuable.

Examples

A fuel filler design where the diesel nozzle won't fit gasoline vehicles prevents misfueling—the error is physically impossible. This prevention-level mistake-proofing is more effective than warning labels or training.

Key Points

- Prevention is more effective than detection; detection is more effective than warning

- Mistake-proofing acknowledges human fallibility and designs around it

- Simple, reliable solutions are better than complex ones

- Look for mistake-proofing opportunities wherever errors occur repeatedly

Common Misconceptions

Mistake-proofing blames the process for human errors. Mistake-proofing acknowledges that humans will err regardless of training or motivation. It's not blame—it's realistic system design that accounts for human factors.

Only experts can design mistake-proofing. Workers closest to errors often devise the best mistake-proofing solutions. Their direct experience with failure modes informs creative prevention.