Predictive Maintenance

Personalize This

Get insights for your role

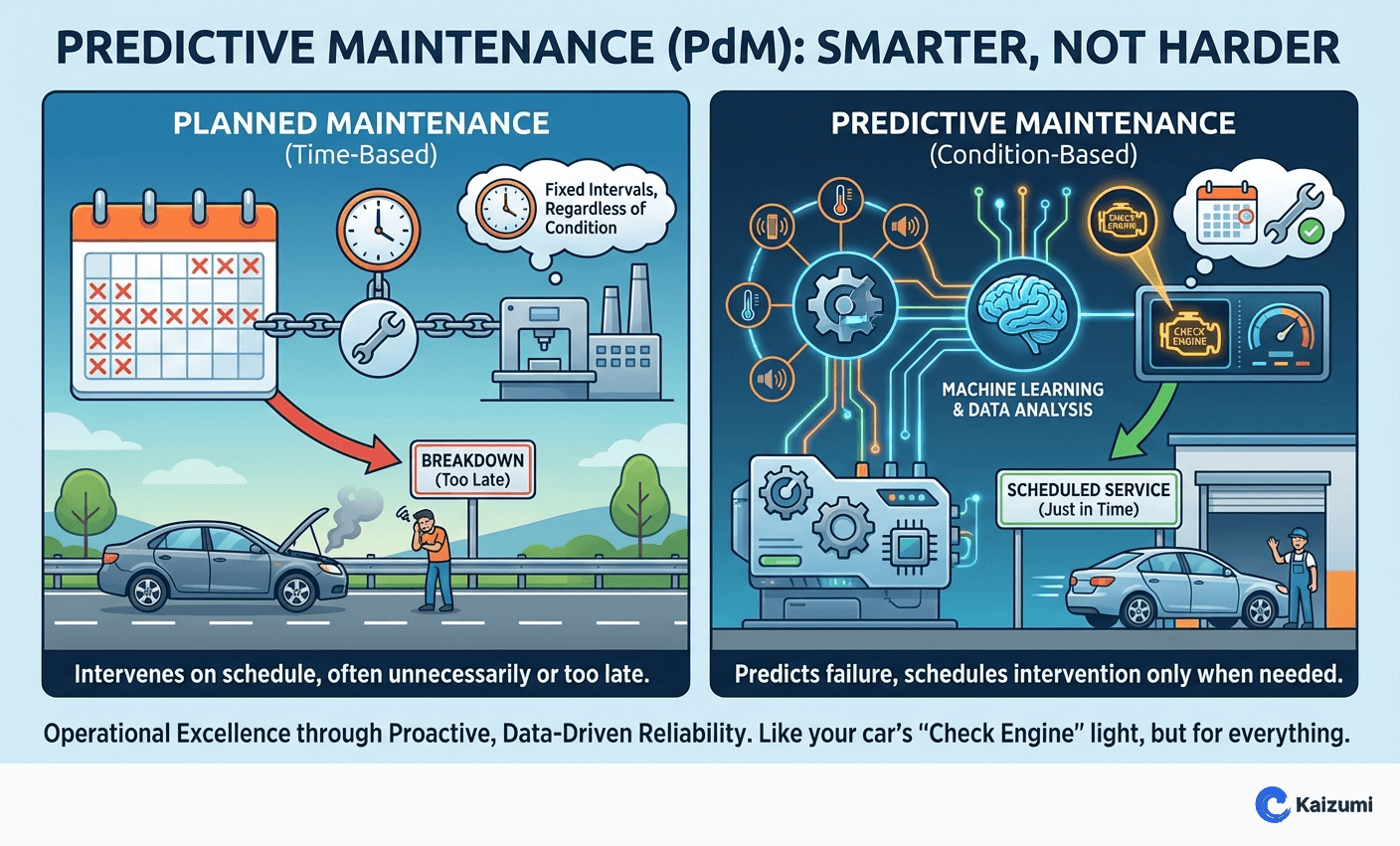

Predictive maintenance uses condition monitoring and data analysis to predict equipment failures and schedule maintenance before breakdowns occur.

Definition

Predictive maintenance (PdM) uses condition monitoring, data analysis, and machine learning to predict when equipment will fail and schedule maintenance accordingly. Unlike time-based planned maintenance that intervenes at fixed intervals regardless of condition, predictive maintenance bases intervention on actual equipment state. Monitoring technologies include vibration analysis, thermal imaging, oil analysis, ultrasonic testing, and sensor data analytics. PdM optimizes maintenance timing—intervening early enough to prevent failure but late enough to maximize component life.

Examples

A paper mill installed vibration sensors on critical bearings. Machine learning algorithms detected subtle vibration pattern changes indicating bearing degradation. Maintenance was scheduled before failure during a planned shutdown—avoiding $200,000 in unplanned downtime costs per incident.

Key Points

- Bases maintenance timing on actual equipment condition, not fixed schedules

- Technologies: vibration analysis, thermography, oil analysis, sensor analytics

- Optimizes the tradeoff between too-early and too-late intervention

- Requires investment in monitoring technology and analytical capability

Common Misconceptions

Predictive maintenance eliminates all failures. PdM catches degradation-based failures with detectable signatures. Random failures, manufacturing defects, and operator-induced damage may not produce early warning signals. PdM reduces, not eliminates, unexpected failures.

More sensors mean better prediction. Effective PdM requires the right sensors monitoring the right failure modes. Data without analytical capability or clear failure signatures produces noise, not insight. Start with known failure modes and build monitoring around them.