Planned Maintenance

Personalize This

Get insights for your role

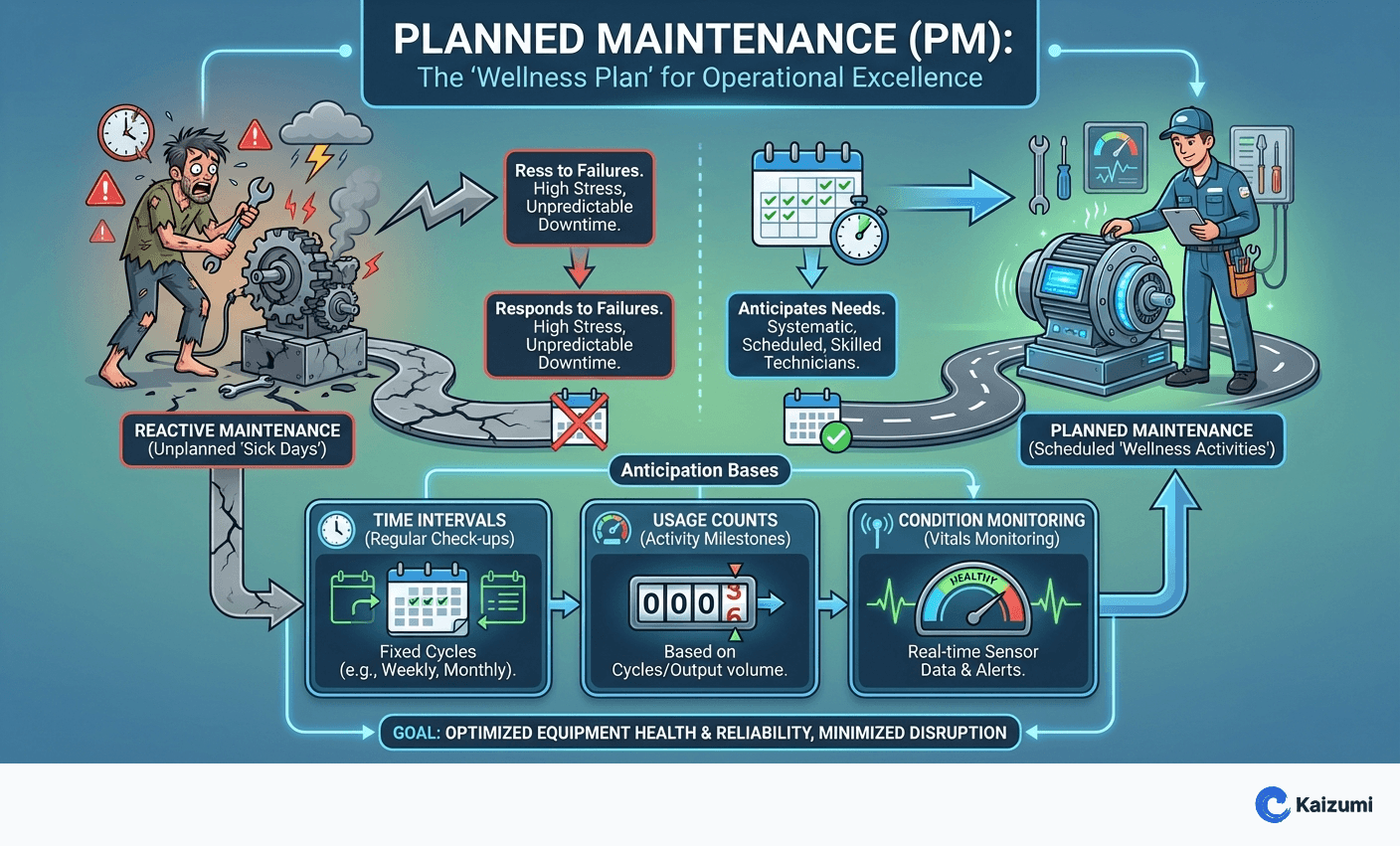

Planned maintenance is scheduled, proactive equipment maintenance performed at predetermined intervals to prevent breakdowns and extend equipment life.

Definition

Planned maintenance (PM) is the TPM pillar focused on systematic, scheduled maintenance activities performed by skilled technicians. Unlike reactive maintenance that responds to failures, planned maintenance anticipates equipment needs based on time intervals, usage counts, or condition monitoring. PM activities include periodic inspections, component replacement, calibration, and overhauls—all scheduled to minimize production disruption. The goal is zero breakdowns through proactive intervention.

Examples

A plastics manufacturer implemented planned maintenance scheduling based on machine hours. Injection molding machines received scheduled bearing replacement, hydraulic fluid changes, and electrical inspections. Unplanned breakdowns dropped 75%, and maintenance costs decreased as emergency repairs became rare.

Key Points

- Scheduled based on time intervals, usage, or condition indicators

- Performed by skilled maintenance technicians

- Complements autonomous maintenance (operator-performed care)

- Goal is zero breakdowns through proactive intervention

Common Misconceptions

More planned maintenance is always better. Over-maintenance wastes resources and can introduce problems through unnecessary intervention. Optimal PM intervals balance prevention cost against failure cost. Data-driven scheduling outperforms arbitrary frequencies.

Planned maintenance eliminates all breakdowns. PM significantly reduces breakdowns but cannot eliminate them entirely. Random failures, infant mortality, and unforeseen issues still occur. PM shifts the balance from reactive to proactive, but some reactive capacity remains necessary.