Speed Loss

Personalize This

Get insights for your role

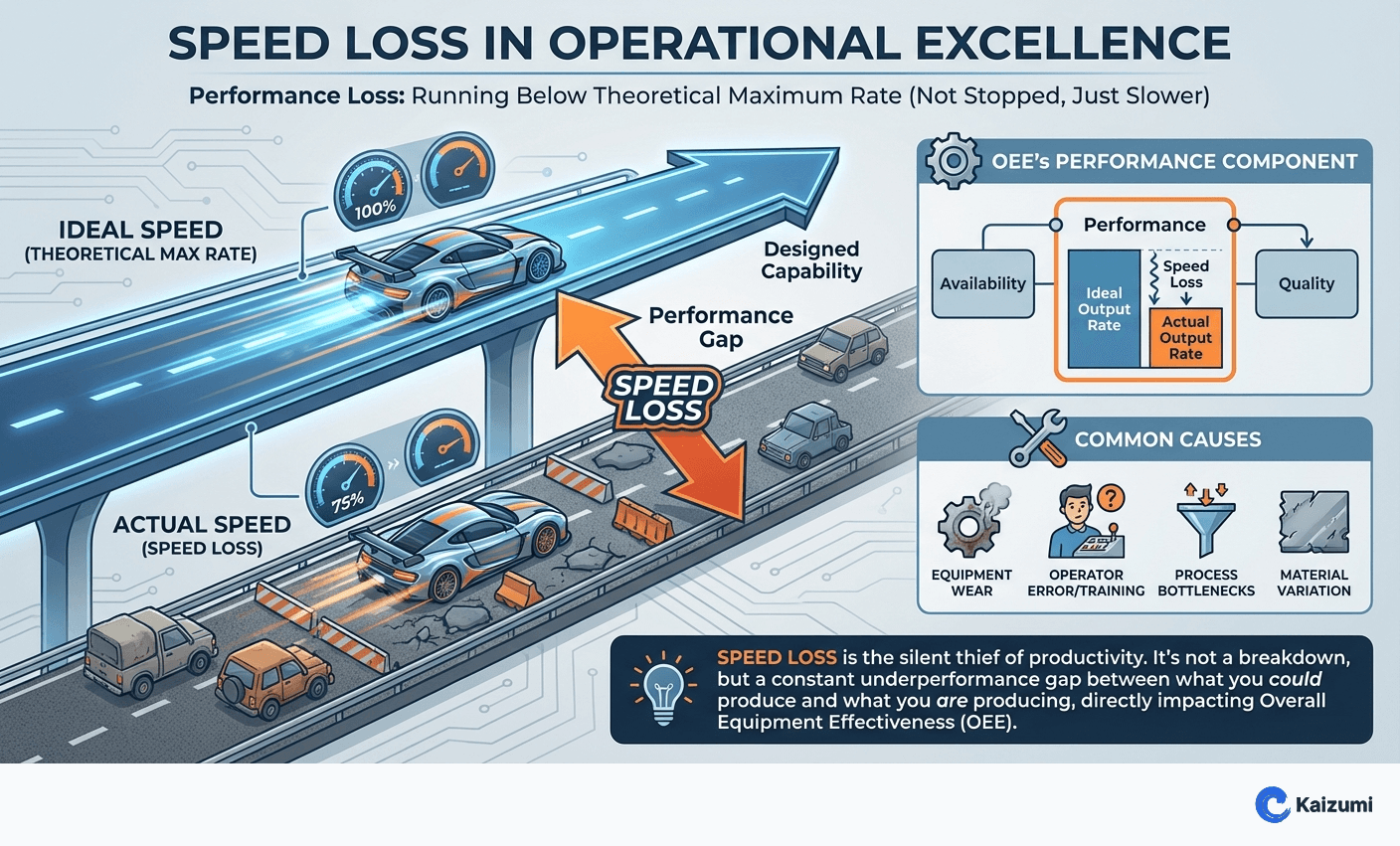

Speed loss is the gap between actual equipment running speed and its designed maximum rate, reducing output without causing stops.

Definition

Speed loss is the performance loss when equipment runs below its theoretical maximum rate. The equipment isn't stopped, but it's producing slower than designed capability. Speed loss appears in OEE's Performance component—the gap between actual output rate and ideal rate. Causes include equipment wear, conservative operator settings, material variation, process limitations, and lack of knowledge about true equipment capability. Speed losses are often invisible because equipment appears to be "running fine."

Examples

A stamping press was designed for 60 strokes per minute but ran at 45 due to quality concerns at higher speeds. Investigation revealed that worn die components caused the quality issues. After die refurbishment, the press ran reliably at 58 strokes per minute—29% more output with no additional equipment.

Key Points

- Equipment running but below maximum rated speed

- Often invisible—equipment appears to be working fine

- Causes: wear, conservative settings, material issues, forgotten slowdowns

- Part of OEE Performance calculation

Common Misconceptions

Rated speed is always achievable. Some equipment never runs at nameplate speed due to material, environmental, or process constraints. The practical maximum may be below theoretical maximum. Understanding true capability matters.

Running slower is always bad. Sometimes running below maximum extends equipment life, improves quality, or matches downstream capacity. Speed loss is only "loss" when faster operation would add value without creating other problems.