Stability

Personalize This

Get insights for your role

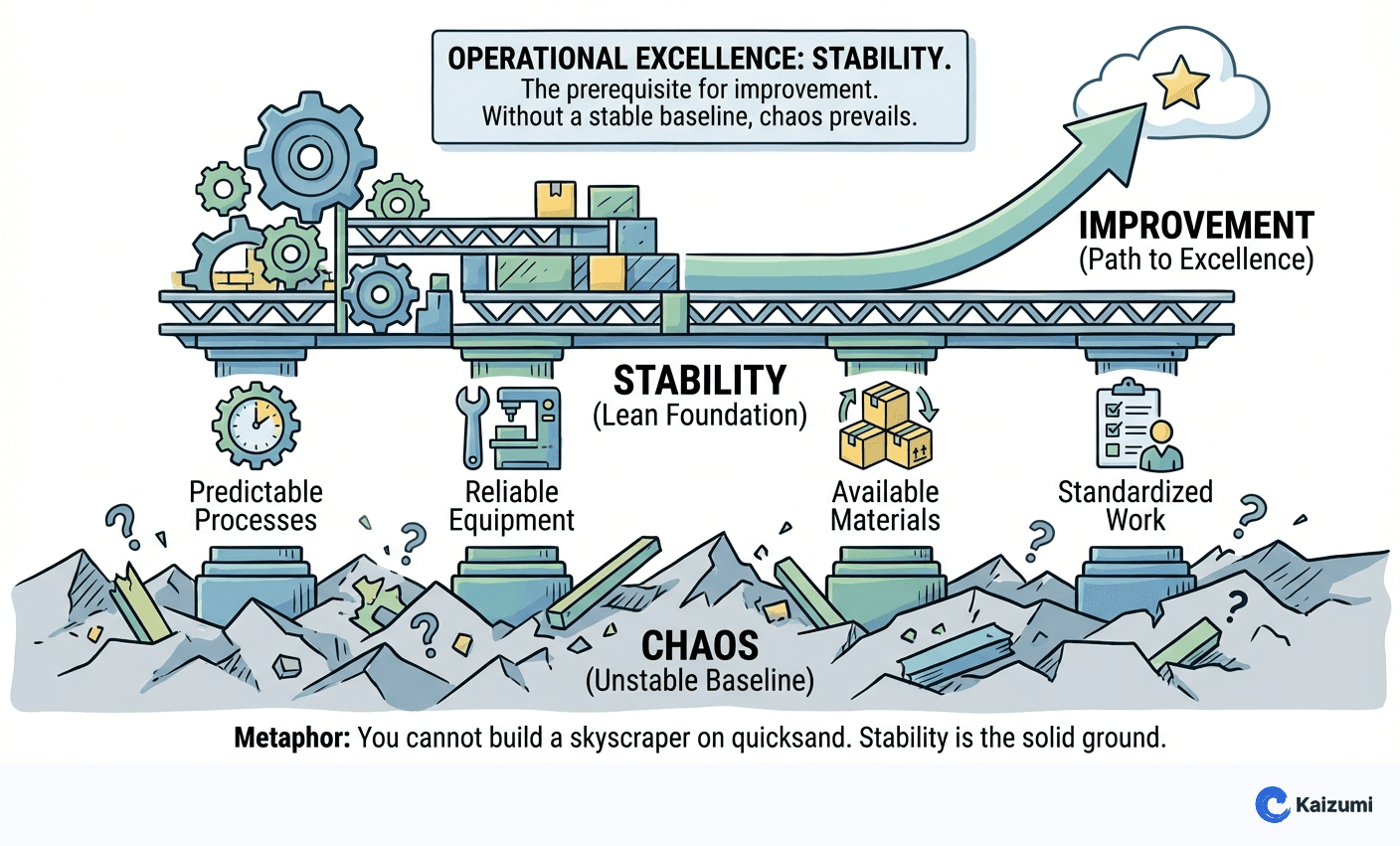

Stability is the foundational state of predictable, reliable processes that enables continuous improvement and lean operations.

Definition

Stability in lean thinking refers to the foundational state where processes are predictable, equipment is reliable, materials are available, and work is standardized. Stability is prerequisite for improvement—you cannot improve a chaotic process because there's no baseline to improve from. The lean journey typically begins by establishing basic stability: reliable equipment through maintenance, consistent methods through standardization, capable processes through quality improvement, and available materials through supply chain management. Only with stability can flow, pull, and continuous improvement function effectively.

Examples

A plant attempted to implement kanban but found it impossible because equipment breakdowns were unpredictable. They stepped back to establish stability first—implementing basic preventive maintenance until equipment ran reliably. Only then could kanban function without constant expediting and workarounds.

Key Points

- Stability is foundation—attempting advanced lean tools without stability fails

- Stability doesn't mean static; it means predictable and controllable

- Equipment reliability, process capability, and method consistency all contribute

- Stability must be maintained; it's not a one-time achievement

Common Misconceptions

Stability means no change. Stability means controlled, predictable processes—a foundation for deliberate improvement. Stable processes are changed intentionally and systematically, not chaotically.

We can skip stability and implement advanced tools. Advanced lean tools like kanban, heijunka, and cells require underlying stability. Without stability, these tools create more chaos rather than improvement.