Standardization

Personalize This

Get insights for your role

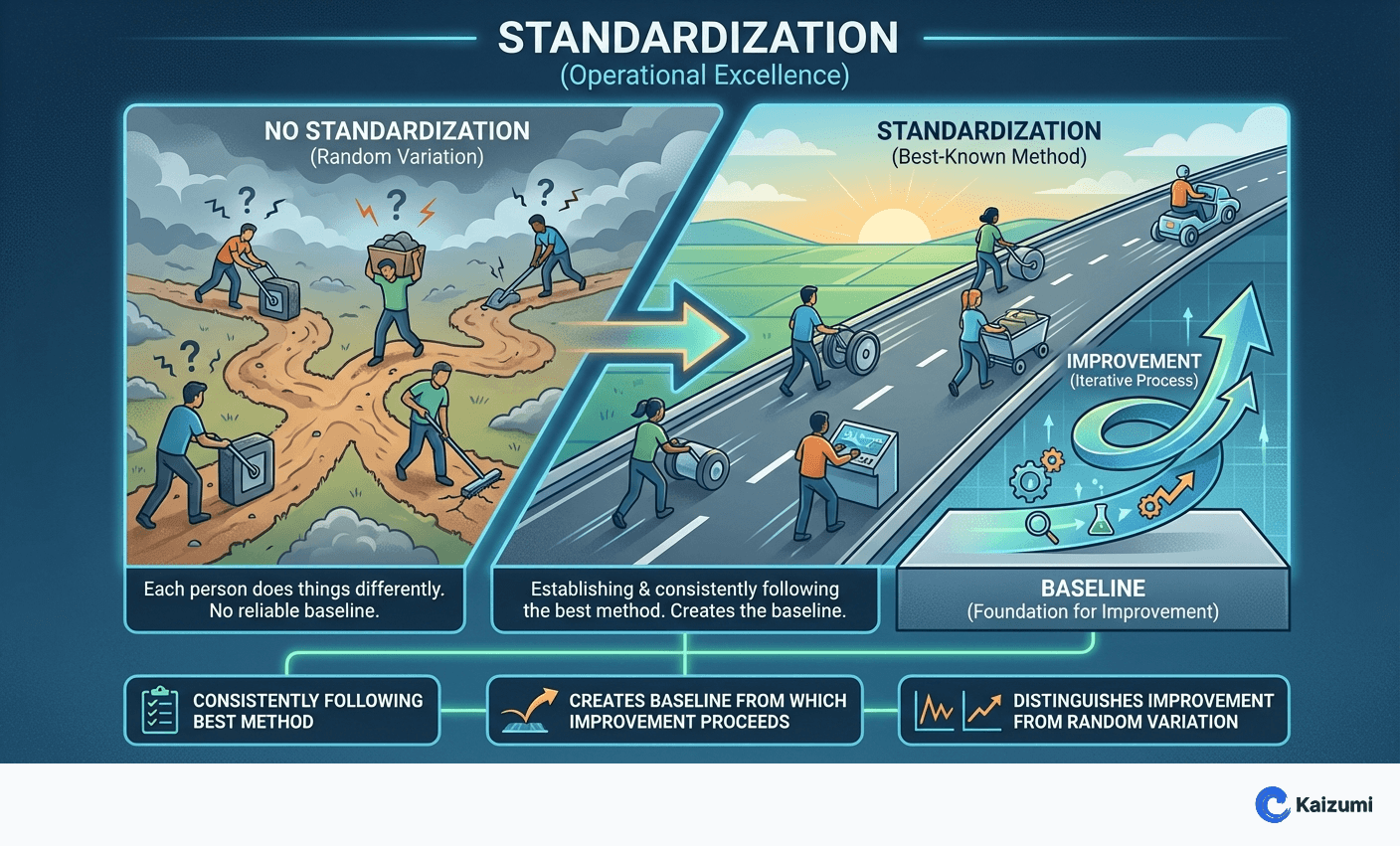

Standardization is establishing and following the current best-known method for performing work consistently and predictably.

Definition

Standardization is the practice of establishing and consistently following the best-known method for performing work. It creates the baseline from which improvement proceeds. Without standardization, there's no way to distinguish improvement from random variation—each person does things differently, so outcomes vary unpredictably. Standardization isn't about rigid rules that prevent thinking; it's about capturing current best practice so that everyone benefits from what's been learned and so that improvements can be systematically tested against the standard.

Examples

An assembly process had quality issues because each operator used slightly different methods. Standardization documented the best-known sequence and technique. Quality improved immediately as everyone used the superior method. Further improvements were tested against the standard and incorporated when proven better.

Key Points

- Standardization captures current best-known method, not permanent rules

- Standards should be changed when better methods are discovered

- Without standardization, you cannot systematically improve

- Standards must be visual, accessible, and actively followed

Common Misconceptions

Standardization prevents creativity. Good standardization creates a foundation for creativity by establishing what's known. Innovation happens by testing improvements against standards, not by random variation.

Standardization is bureaucratic compliance. Lean standardization is owned by the people doing the work, updated frequently as improvements are discovered, and serves as a tool for improvement rather than a constraint.