Supermarket

Personalize This

Get insights for your role

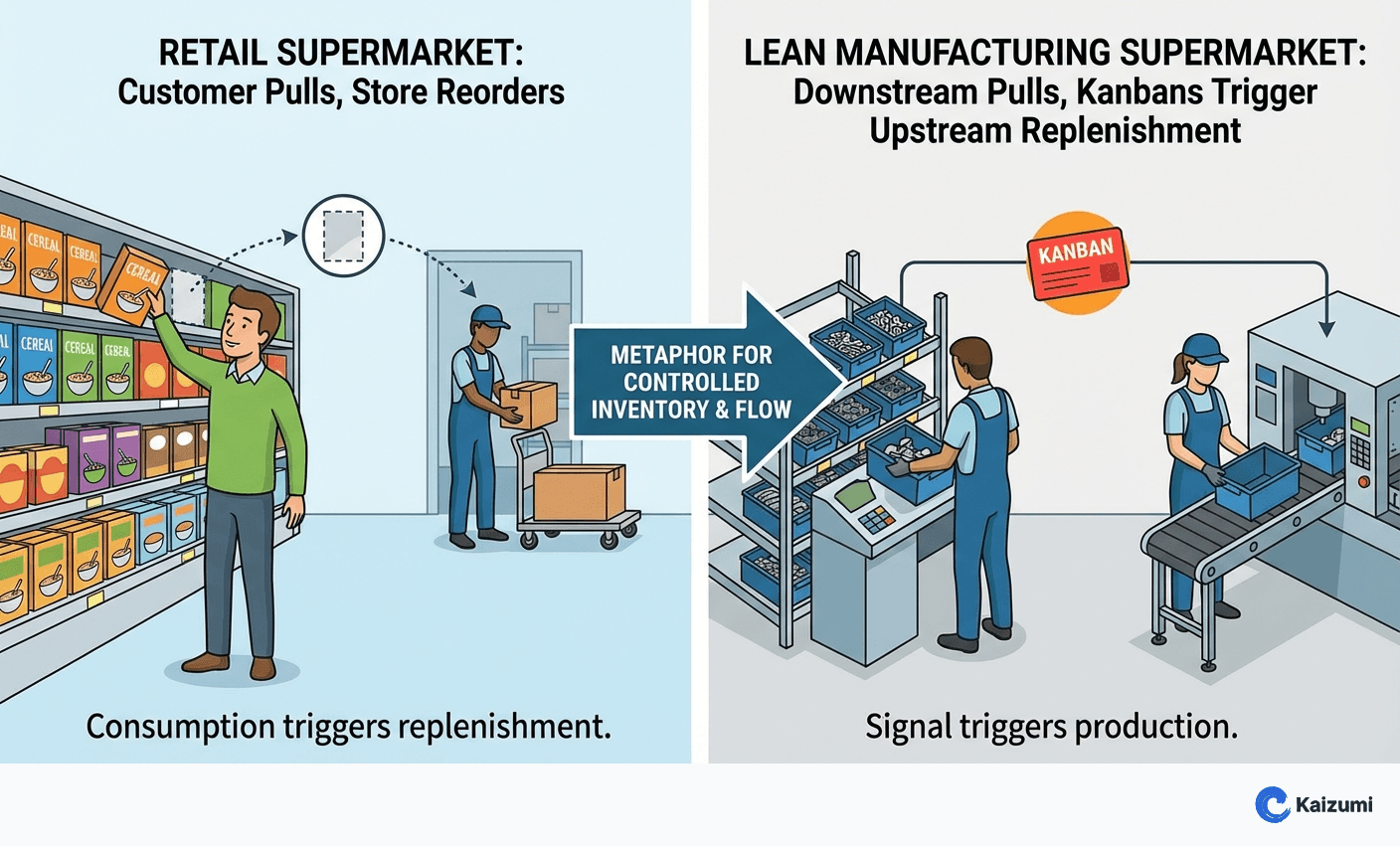

A supermarket is a controlled inventory location where products are stored for downstream pull, similar to retail supermarket shelves.

Definition

A supermarket in lean manufacturing is a controlled inventory location where products or components are stored until needed by a downstream process, analogous to a retail supermarket shelf. When items are consumed from the supermarket, a kanban signal triggers upstream replenishment. Supermarkets are used between processes that cannot be directly linked in continuous flow—perhaps due to different cycle times, distance, or process constraints. The supermarket provides a buffer that enables pull while keeping inventory controlled and visible.

Examples

A fabrication area feeds multiple assembly lines with different demands. A supermarket holds standard components in designated locations. When assembly consumes parts, kanban cards return to fabrication, triggering replenishment. The supermarket decouples fabrication from assembly while maintaining pull.

Key Points

- Supermarkets enable pull systems where continuous flow isn't possible

- Each location has a designated part, quantity, and visual control

- Consumption triggers replenishment through kanban signals

- Supermarkets control inventory while ensuring availability

Common Misconceptions

Supermarkets are just organized storage. Supermarkets are linked to pull signals—consumption automatically triggers replenishment. Without this link, they're just warehouses.

Supermarkets should be minimized everywhere. Supermarkets are strategic inventory locations that enable pull. The goal isn't eliminating supermarkets but right-sizing them for their decoupling function.