Pull System

Personalize This

Get insights for your role

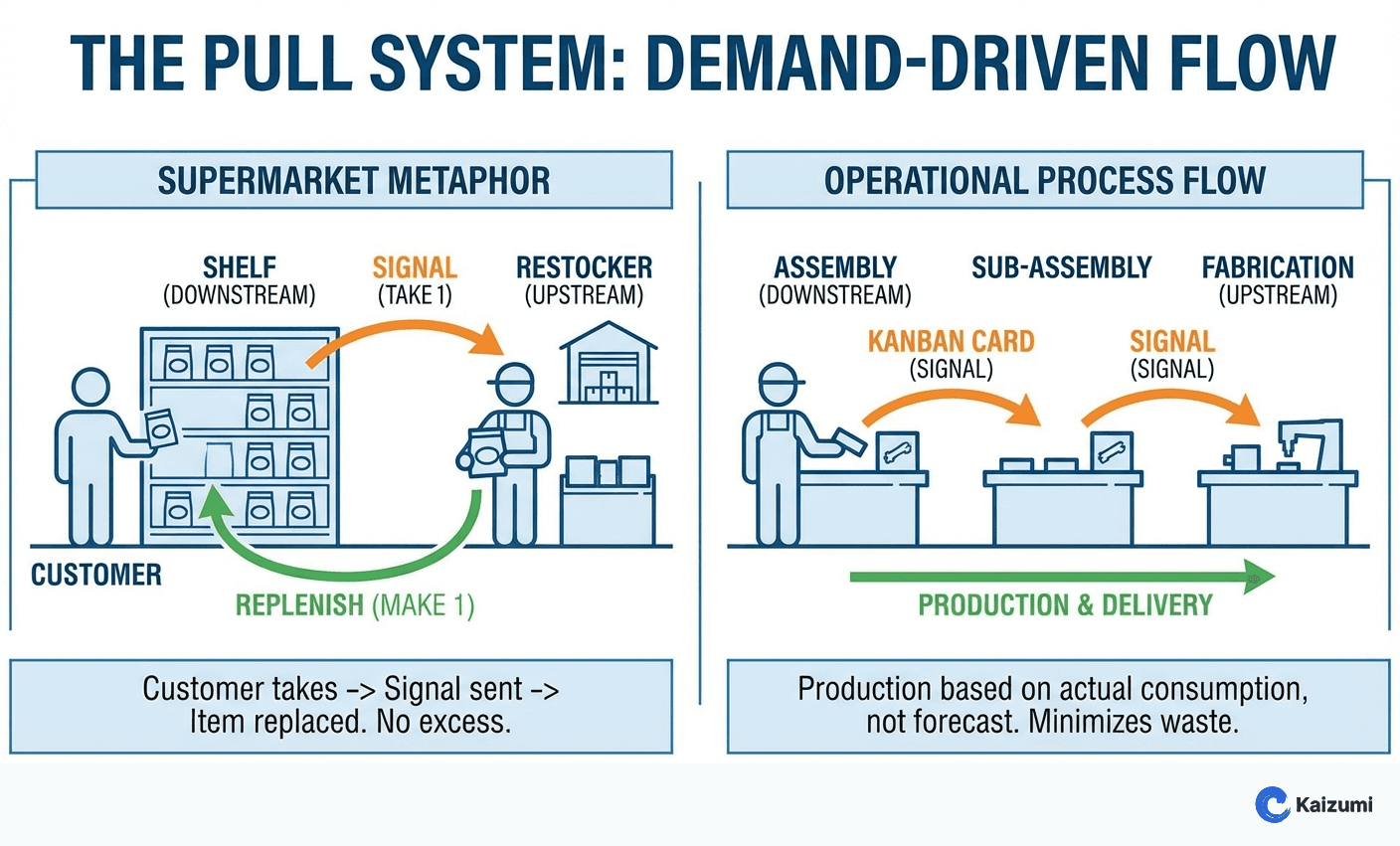

A pull system produces only when downstream processes signal demand, preventing overproduction and enabling flow.

Definition

A pull system is a production control method where upstream processes produce only when downstream processes signal that they have consumed material and need replenishment. This contrasts with push systems where production is based on forecasts and schedules, producing regardless of actual downstream demand. Pull systems prevent overproduction—the most serious of the seven wastes—by linking production directly to consumption. Kanban cards or signals are the most common mechanism for implementing pull, though any method that triggers production based on actual demand qualifies.

Examples

An assembly cell uses a two-bin kanban system for components. When operators empty one bin, they place it in a return lane while drawing from the second bin. The empty bin signals the upstream process to replenish. No signal, no production—this simple pull system eliminated the chronic overproduction that previously cluttered the area.

Key Points

- Pull systems link production authority to actual consumption, not forecasts

- The pull signal can be physical (empty container, card) or electronic

- Pull requires controlled inventory buffers—supermarkets—between processes that can't achieve continuous flow

- Pull systems make overproduction impossible by design

Common Misconceptions

Pull systems eliminate all inventory. Pull systems reduce inventory dramatically but require strategic buffers (supermarkets) between processes that can't be directly linked. The goal is controlled, visible inventory rather than zero inventory.

Pull systems can't handle demand variation. Pull systems handle variation by consuming from supermarket buffers, which are then replenished. Large demand spikes may require additional capacity or buffer inventory, but pull handles normal variation well.