Waste

Personalize This

Get insights for your role

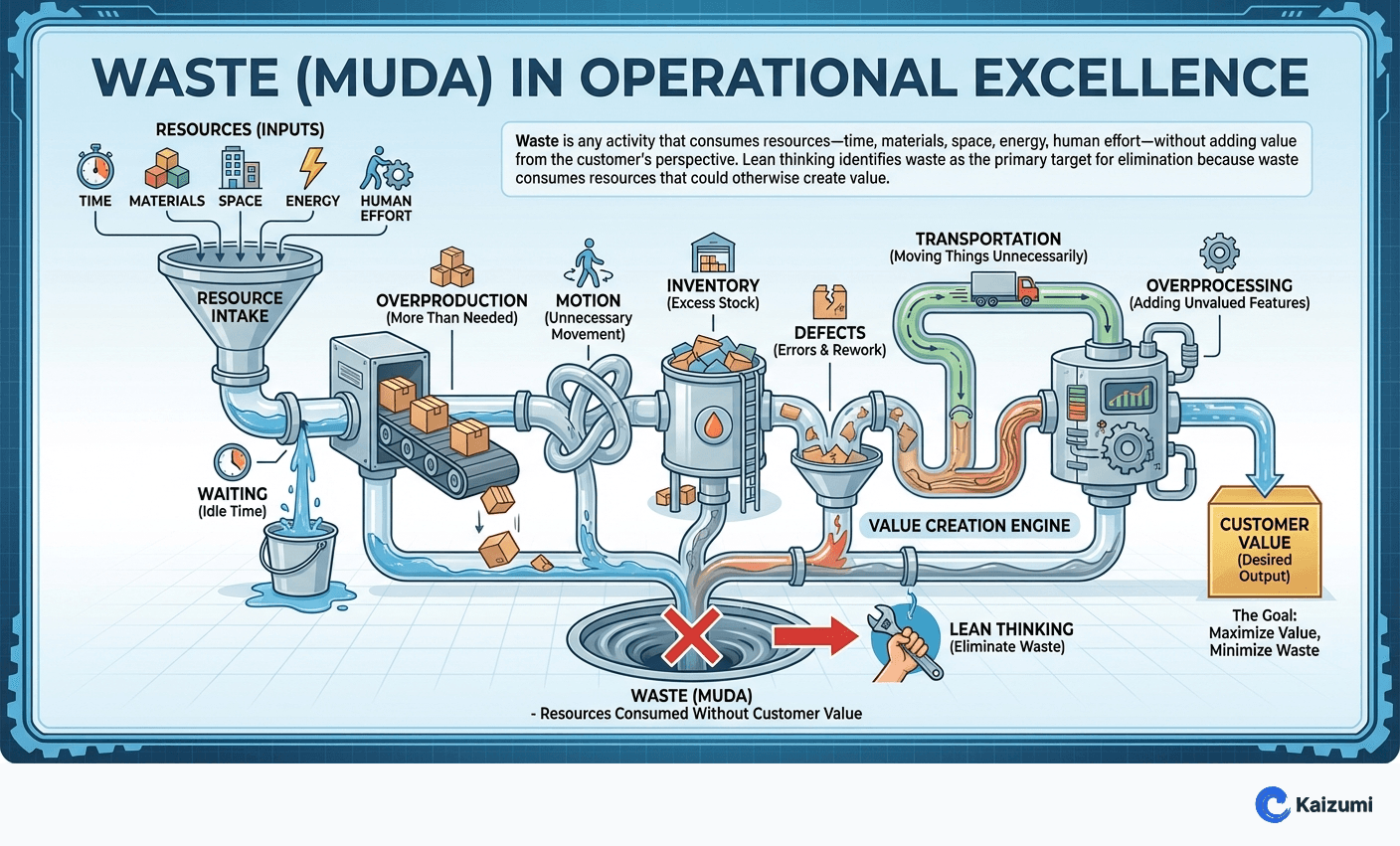

Waste is any activity that consumes resources without creating value for the customer - the target of lean improvement.

Definition

Waste (muda in Japanese) is any activity that consumes resources—time, materials, space, energy, human effort—without adding value from the customer's perspective. Lean thinking identifies waste as the primary target for elimination because waste consumes resources that could otherwise create value. The traditional seven wastes are: overproduction, waiting, transportation, overprocessing, inventory, motion, and defects. Some frameworks add an eighth waste: underutilized human potential. Identifying and eliminating waste is the fundamental activity of lean improvement.

Examples

A time study revealed that operators spent only 15% of their time on value-adding assembly work. The remaining 85% consisted of waste: walking to get parts (motion), waiting for the previous station (waiting), moving subassemblies between stations (transportation), and fixing defects (rework). Each waste category represented improvement opportunity.

Key Points

- Waste should be visible—hidden waste can't be eliminated

- Overproduction is considered the worst waste because it drives all others

- Some waste is currently necessary (Type 1) while other waste can be eliminated immediately (Type 2)

- Waste elimination is ongoing—today's necessity may become tomorrow's waste

Common Misconceptions

All waste can be eliminated immediately. Some waste exists because we haven't yet solved underlying problems. The goal is continuous waste reduction, not instant perfection. Identifying waste as waste is the first step toward eventual elimination.

Waste elimination means working harder. Eliminating waste actually makes work easier by removing unnecessary effort. When motion waste is reduced, workers walk less. When defect waste is reduced, there's no rework. Waste elimination improves working conditions.