Yamazumi

山積み·yamazumi·"stacking, piling up"

Personalize This

Get insights for your role

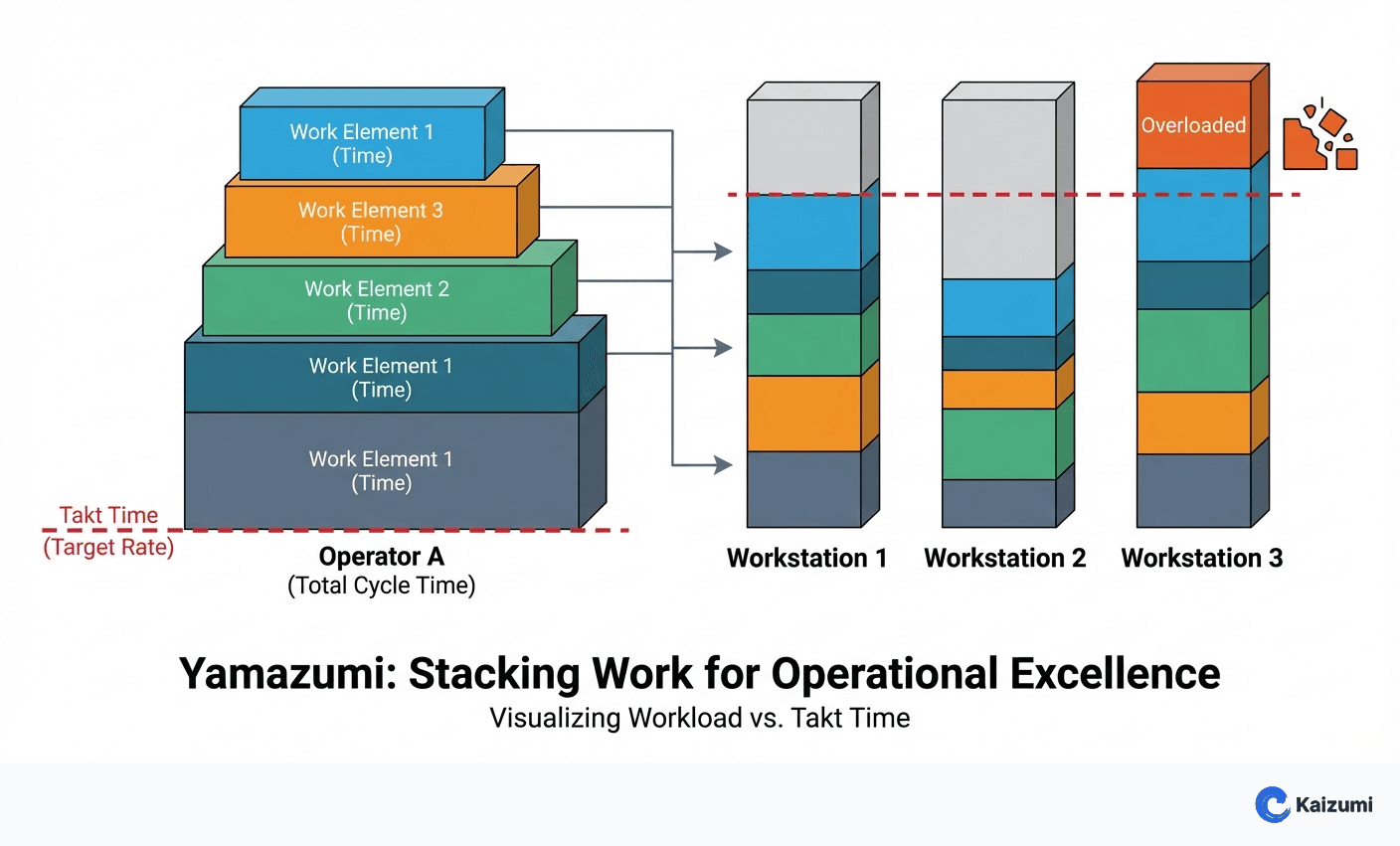

Yamazumi is a visual stacked bar chart showing work element times against takt time to reveal imbalances and improvement opportunities.

Definition

Yamazumi (meaning "stacking" or "piling up") is a visual tool that displays work element times stacked in bars for each workstation or operator, compared against takt time. Each bar represents a position; each stack segment represents a work element. When bars exceed takt time, the position is overloaded. When bars are significantly under takt time, there's unused capacity. Yamazumi charts reveal line balance, identify bottlenecks, and highlight opportunities to redistribute work. They're essential for line balancing and standardized work development.

Examples

An assembly line yamazumi showed six stations with work times ranging from 42 to 68 seconds against a 55-second takt time. The overloaded station (68 seconds) was the bottleneck; underloaded stations had unused capacity. Redistributing work elements across stations improved balance and increased output.

Key Points

- Yamazumi visualizes the relationship between work content and takt time

- Bars above takt time identify bottlenecks; bars far below indicate unused capacity

- Work elements should be accurate—poor time data leads to poor decisions

- Yamazumi guides line balancing decisions and highlights improvement targets

Common Misconceptions

Yamazumi shows perfect balance as the goal. Perfect balance at takt time leaves no buffer for variation. Some balance below takt time provides stability; the amount depends on process capability.

Yamazumi is only for assembly lines. Any process with sequential steps and measurable work elements can use yamazumi. Service processes, administrative workflows, and healthcare procedures all benefit from this visual analysis.