3P (Production Preparation Process)

Personalize This

Get insights for your role

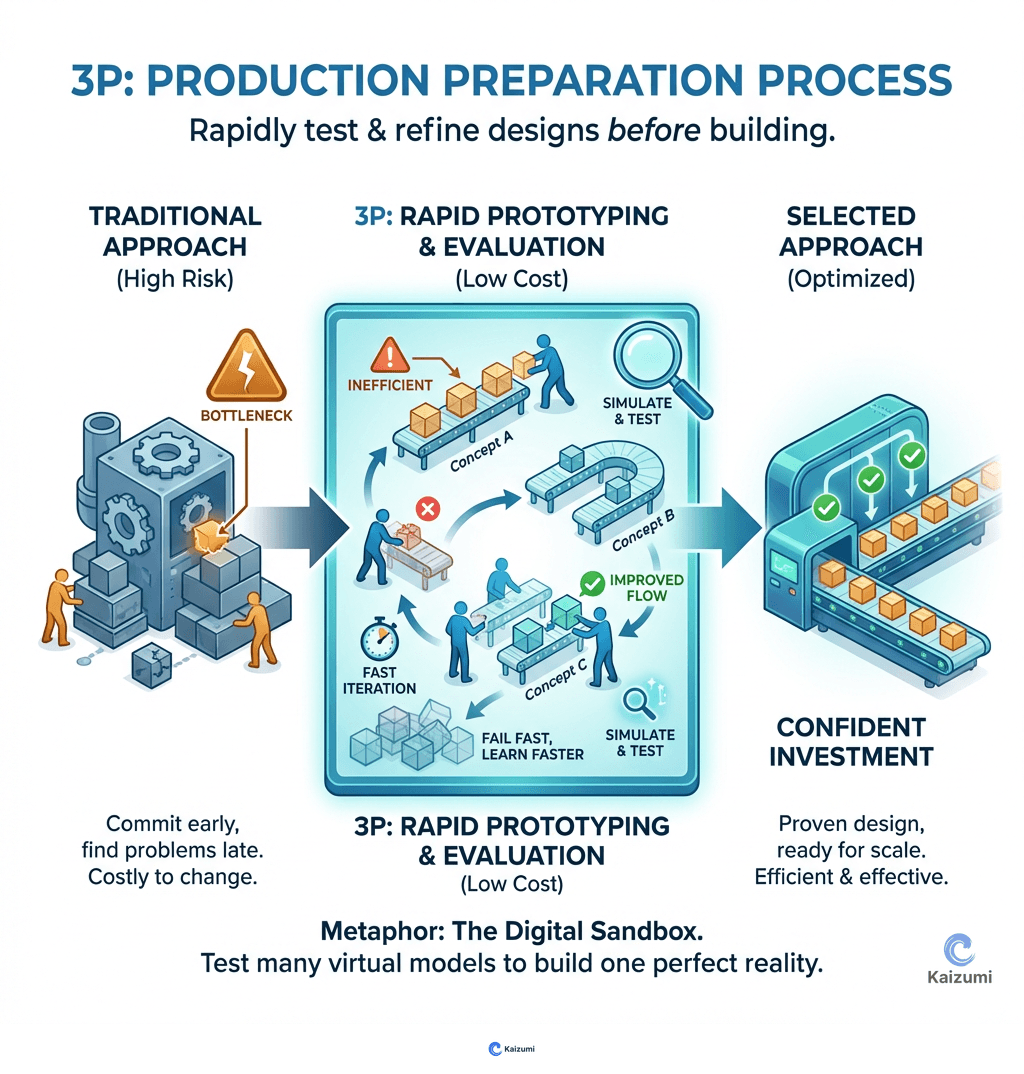

3P is a structured method for designing new production processes or products that builds lean thinking into the design from the start.

Definition

3P (Production Preparation Process) is a structured methodology for designing new production processes, equipment, or facilities with lean principles built in from the start. Rather than designing first and then kaizening a flawed system, 3P engages cross-functional teams in rapid prototyping and evaluation of multiple alternatives before committing to final design. Teams use cardboard mockups, simulations, and trystorming (trying ideas physically) to explore options. 3P dramatically compresses design timelines while producing processes with better flow, lower cost, and higher quality than traditional design approaches.

Examples

When launching a new product line, a company used 3P instead of traditional engineering. A cross-functional team spent one week creating seven different process concepts using cardboard, foam, and PVC pipe. They evaluated each for flow, flexibility, and operator motion, then combined the best elements into a final design. The line launched with 30% less floor space and 40% better productivity than traditional design would have achieved.

Key Points

- Design lean in rather than kaizen waste out—prevention over correction

- Multiple alternatives explored before commitment—not single-option refinement

- Cross-functional participation including operators who will do the work

- Rapid physical prototyping to test ideas before investing in final design

Common Misconceptions

3P is just brainstorming. 3P includes physical prototyping and evaluation against specific criteria. Ideas are tested, not just discussed.

3P replaces engineering. 3P complements engineering by engaging broader teams in concept development. Engineers still develop detailed designs from the 3P-selected concept.