Cellular Manufacturing

Personalize This

Get insights for your role

Cellular manufacturing organizes equipment and people into cells that produce complete products or components with minimal handling.

Definition

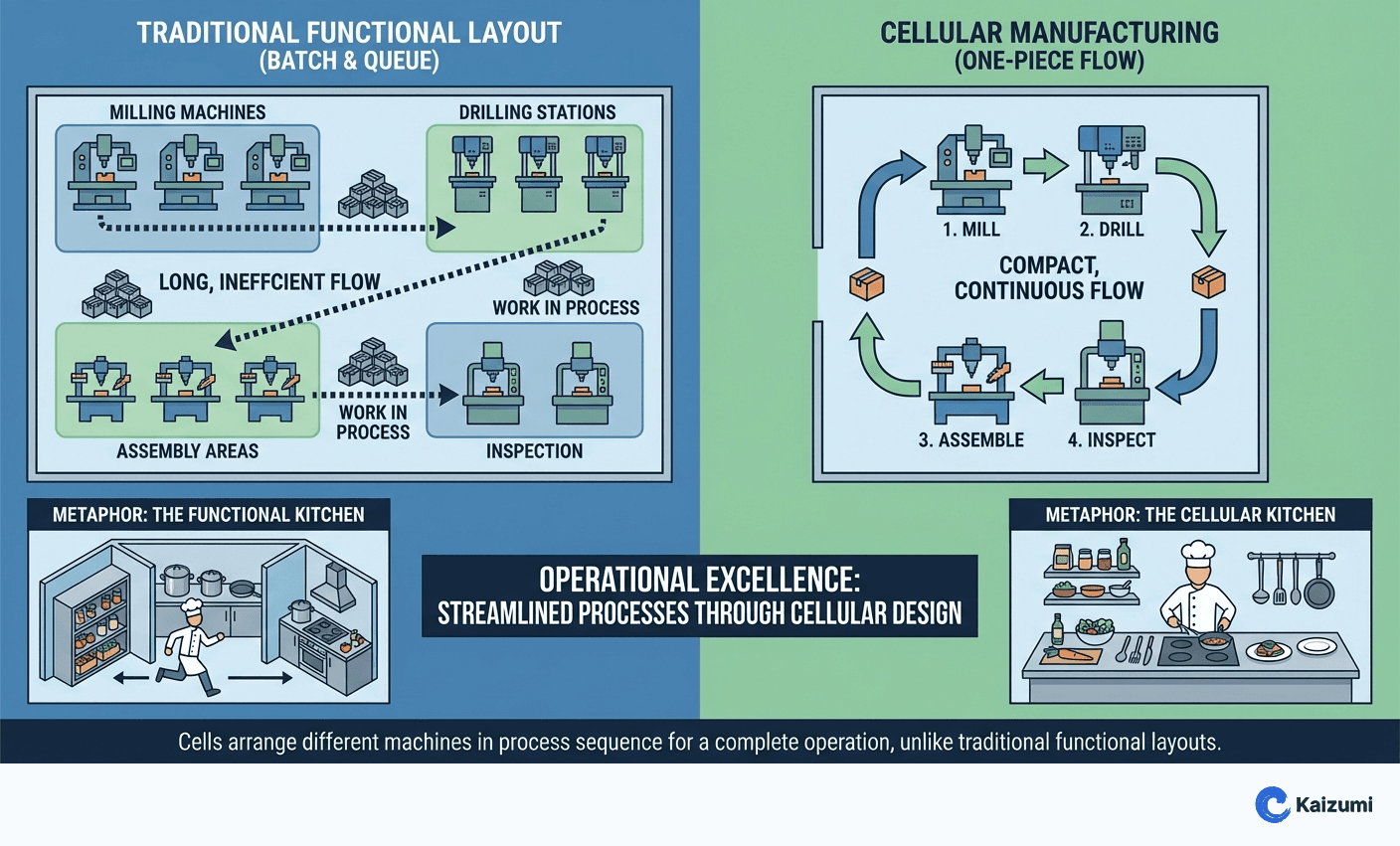

Cellular manufacturing organizes equipment, workstations, and people into compact cells that perform a complete sequence of operations on a product or component. Unlike traditional functional layouts (where all similar machines are grouped together), cells arrange different machines in process sequence, enabling one-piece flow with minimal transportation and waiting. Cells typically serve product families with similar processing requirements. Workers in cells often operate multiple machines and perform multiple operations, requiring cross-training and flexibility.

Examples

A machine shop converted from functional departments (all lathes together, all mills together) to cells organized by product family. A gear cell contained a lathe, mill, and grinder in sequence. Parts that previously traveled 500 feet through departments now moved 10 feet within the cell. Lead time dropped from weeks to hours.

Key Points

- Cells are organized around product/service families, not equipment types

- Cell design enables one-piece flow and minimal transportation

- Multi-skilled workers operate multiple steps within the cell

- Cells create ownership and visibility of the complete process

Common Misconceptions

Cellular manufacturing requires new equipment. Cells can be created by rearranging existing equipment. The key is organizing around process flow, not necessarily buying new machines.

Cells only work for manufacturing. The principle of organizing around complete work sequences applies to any process. Service cells, care cells, and administrative cells all use the same concepts.