A-B Control

Personalize This

Get insights for your role

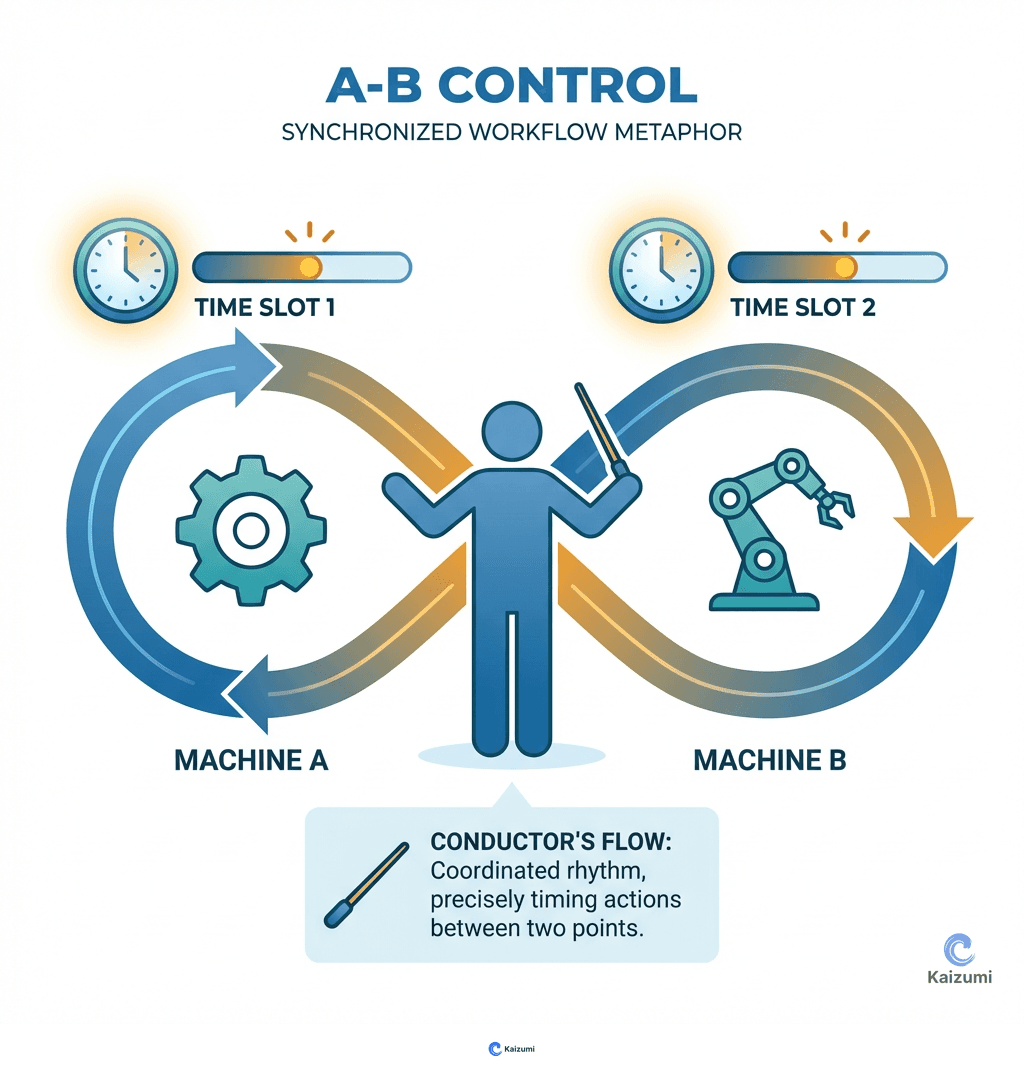

A-B Control is a method for managing two machines or processes with one operator by establishing a fixed work sequence between them.

Definition

A-B Control is a work management method where one operator runs two machines or processes by following a standardized sequence that synchronizes with both machines' automatic cycles. The operator loads Machine A, starts it, walks to Machine B, unloads the finished piece, loads new material, starts it, then returns to Machine A. The walking time and manual work fit within the machines' automatic cycle times, creating continuous flow without waiting. This method maximizes operator utilization while maintaining consistent output.

Examples

A CNC machining cell has two lathes with 90-second automatic cycles. One operator uses A-B control: load Lathe A (15 seconds), start cycle, walk to Lathe B (10 seconds), unload and load (30 seconds), start cycle, walk back (10 seconds), unload and load Lathe A (30 seconds). The 95 seconds of work fits within the combined cycle time, producing one part every 90 seconds with one operator instead of two.

Key Points

- Requires careful time study to ensure manual work fits within machine cycles

- Walking distance and layout are critical design factors

- Creates standard work that can be taught and audited

- Reduces labor cost per unit while maintaining throughput

Common Misconceptions

A-B Control means the operator is always busy. Well-designed A-B control includes small buffers of time for variation. If the timing is too tight, any disruption cascades into missed cycles and quality problems.

Any two machines can use A-B control. The machines' cycle times must be compatible, and the layout must allow efficient movement between them. Machines with highly variable cycles or those requiring constant attention don't work well in A-B control.