Basic Stability

Personalize This

Get insights for your role

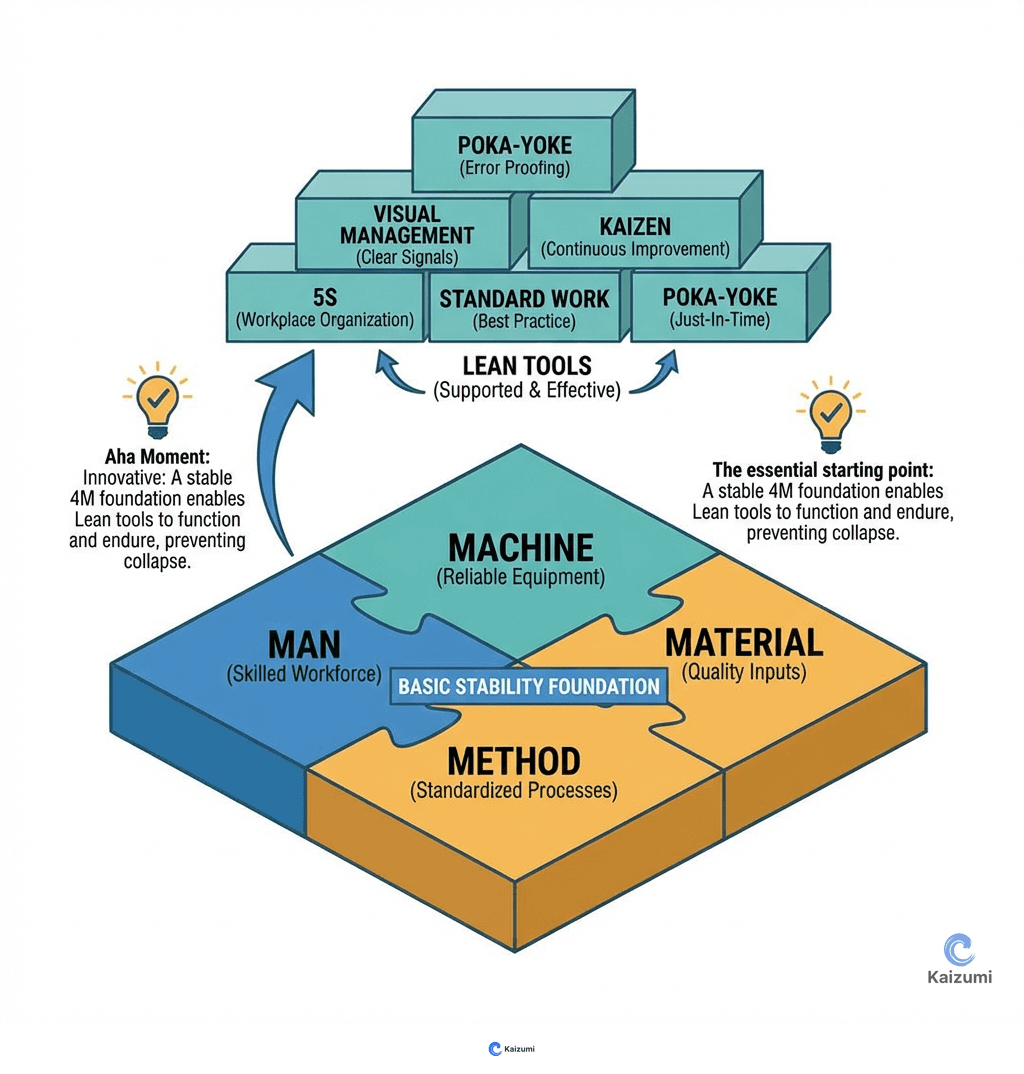

Basic stability is the foundational level of process reliability required before implementing advanced lean tools like kanban or heijunka.

Definition

Basic stability is the minimum level of reliability in the 4Ms—Man (people), Machine (equipment), Material (supplies), and Method (processes)—required before advanced lean systems can function. Without basic stability, sophisticated tools like kanban, heijunka, and single-piece flow will fail because they have no slack to absorb variation. Basic stability means: people are trained and present, machines run reliably, materials arrive as expected, and methods are standardized and followed. Many lean implementations fail because organizations attempt advanced techniques before establishing this foundation.

Examples

A plant attempted kanban but constantly ran out of parts. Investigation revealed machines had 65% uptime due to breakdowns, suppliers missed deliveries 20% of the time, and operators frequently deviated from standard work. Before kanban could succeed, they needed basic stability: TPM to improve uptime, supplier development, and standard work discipline.

Key Points

- The 4Ms must all be stable—weakness in one undermines the others

- Basic stability often requires months of foundational work before advanced tools

- Attempting kanban or heijunka without stability creates frustration and blame

- Stability doesn't mean zero variation, but variation within manageable bounds

Common Misconceptions

Basic stability is boring compared to lean tools. It's unglamorous but essential. Organizations that skip stability work and jump to kanban or cells inevitably retreat when the systems fail under stress.

Once achieved, stability is permanent. Stability requires ongoing maintenance. Equipment degrades, people leave, suppliers change, and processes drift. Continuous attention to the 4Ms is required.