Heijunka

平準化·heijunka·"leveling, smoothing"

Personalize This

Get insights for your role

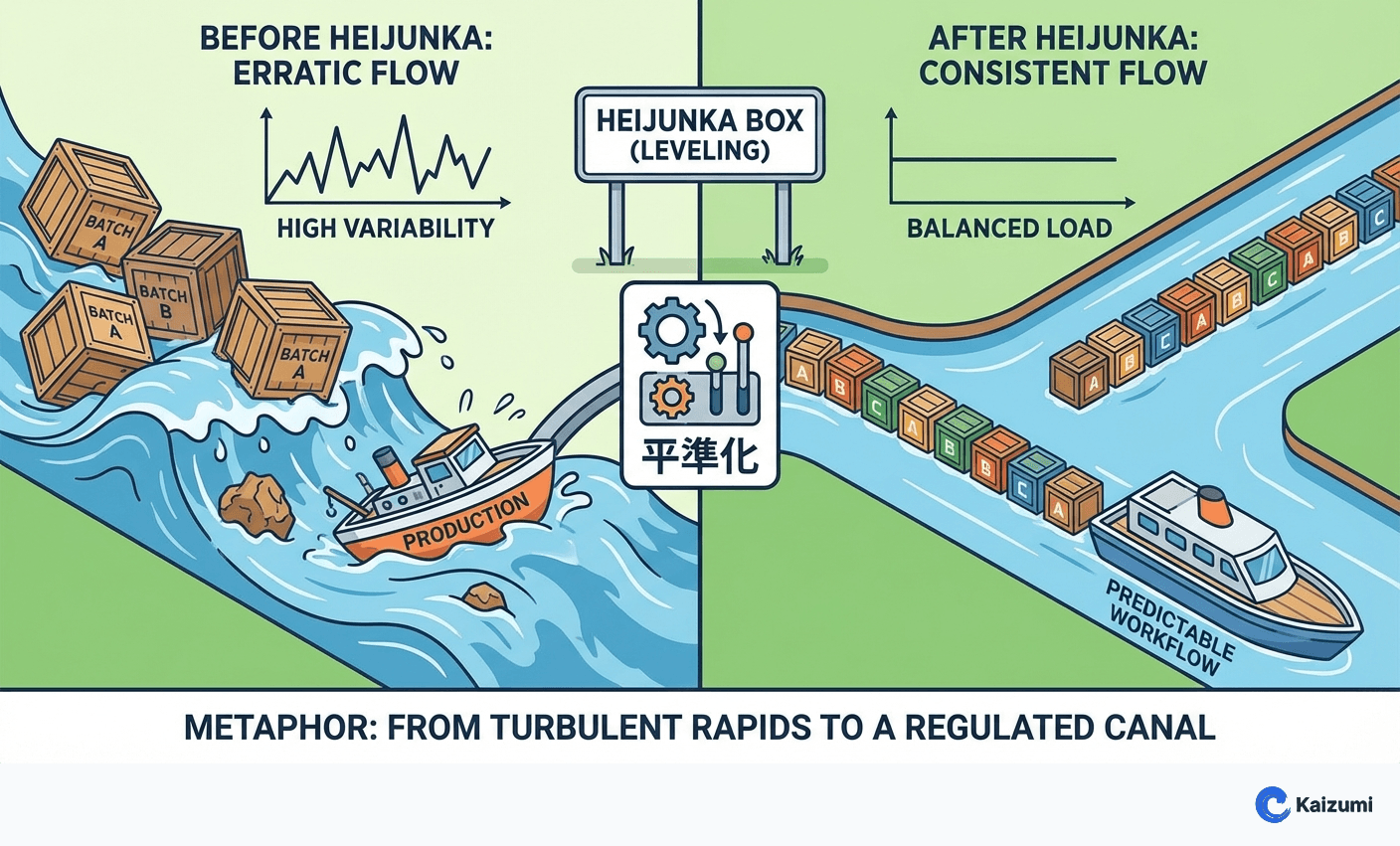

Heijunka is production leveling - smoothing the volume and mix of production to reduce variability and enable consistent flow.

Definition

Heijunka is the practice of leveling production by volume and product mix to create a consistent, predictable workflow. Rather than producing in large batches of a single product type or responding directly to erratic customer demand, heijunka spreads production evenly across the available time. This eliminates the mura (unevenness) that causes peaks and valleys in workload, which in turn creates muri (overburden) during peaks and muda (waste) during valleys. Heijunka is essential for achieving true flow and requires flexibility in changeovers and cross-trained workers.

Examples

A factory producing three product types receives orders in waves—heavy demand for Type A on Mondays, Type B mid-week, and Type C on Fridays. Rather than producing to this pattern, heijunka levels production to build equal quantities of all three types daily. This smooths demand on upstream processes and suppliers while maintaining the same weekly output.

Key Points

- Heijunka addresses both volume leveling (quantity per period) and mix leveling (product variety)

- Leveled production is prerequisite for pull systems and just-in-time to function

- Requires quick changeover capability to produce small batches economically

- Creates predictable rhythm that upstream processes and suppliers can synchronize to

Common Misconceptions

Heijunka means ignoring customer demand. Heijunka smooths production, not demand fulfillment. Finished goods inventory or short lead times can buffer between leveled production and variable customer orders.

Heijunka only applies to manufacturing. Any operation with variable demand benefits from leveling—service scheduling, order processing, project work. The principle of smoothing workload to eliminate peaks and valleys is universal.