Changeover

Personalize This

Get insights for your role

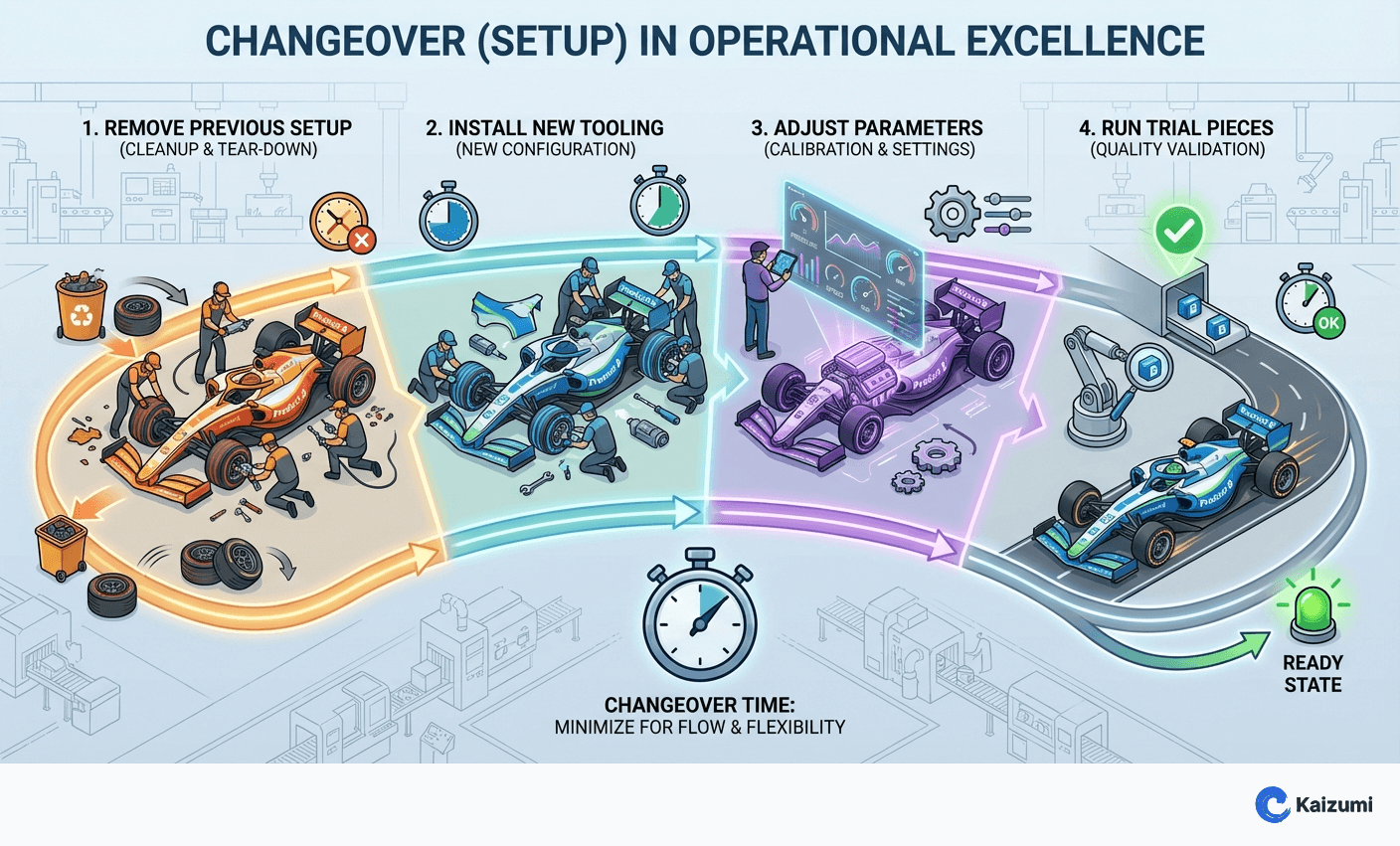

Changeover is the process of converting equipment from producing one product to another, including setup, adjustment, and trial runs.

Definition

Changeover (also called setup) is the process of converting equipment from running one product or configuration to another. It includes removing the previous setup, installing new tooling or settings, adjusting parameters, and running trial pieces until quality is achieved. Changeover time is one of the six big losses affecting OEE availability. Long changeovers encourage large batch sizes to "amortize" setup time, creating flow problems and inventory. SMED (Single-Minute Exchange of Die) is the primary methodology for reducing changeover time.

Examples

An injection molding machine changeover took 90 minutes: 30 minutes removing the old mold, 25 minutes installing the new mold, 20 minutes connecting utilities and adjusting settings, 15 minutes running trial shots. SMED analysis identified opportunities to cut this to 25 minutes.

Key Points

- Includes setup, adjustment, and trial run time until good production

- One of the six big losses affecting OEE availability

- Long changeovers drive large batch sizes and inventory

- SMED methodology targets single-digit minute changeovers

Common Misconceptions

Changeover time is fixed by equipment design. While equipment affects changeover, most changeover time is method-driven. SMED typically reduces changeover 50-90% through improved methods before any equipment modification.

Reducing changeover is only for high-mix environments. Even low-mix operations benefit from changeover reduction—it enables smaller batches, faster response to changes, and reduced inventory. The benefits compound beyond direct time savings.