Setup Reduction

Personalize This

Get insights for your role

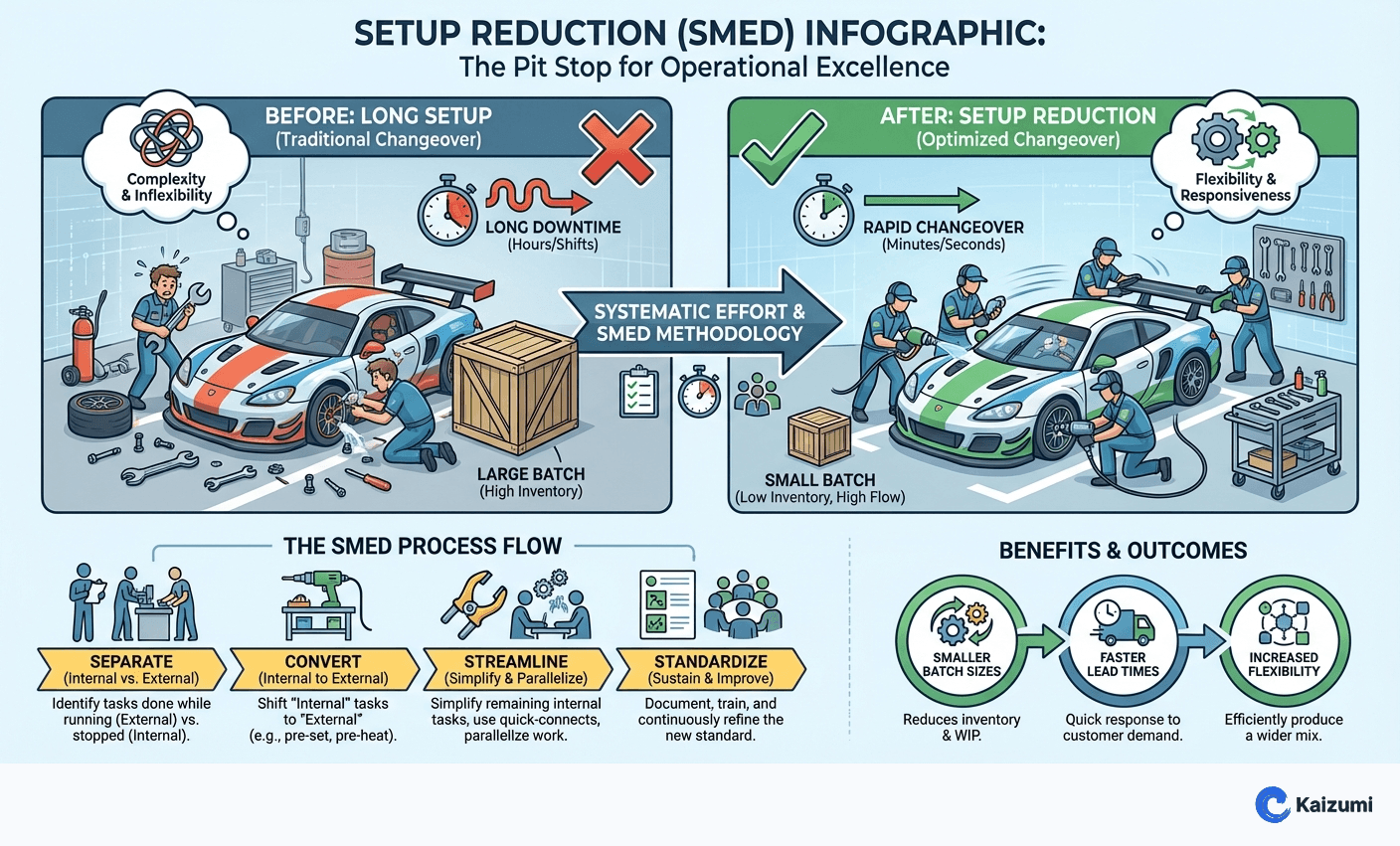

Setup reduction focuses on minimizing the time and effort required to change from one product, batch, or configuration to another.

Definition

Setup reduction is the systematic effort to minimize the time, effort, and resources required to change equipment or processes from one product, batch, or configuration to another. Long setups drive large batch sizes (to amortize the downtime) and reduce flexibility. Setup reduction enables smaller batches, shorter lead times, and better responsiveness to customer demand. Approaches include external preparation, standardization, quick-release mechanisms, and elimination of adjustments.

Examples

Injection mold changeovers traditionally took 3 hours, driving batch sizes of 5,000 pieces. Setup reduction efforts—pre-staging molds, standardizing water connections, eliminating color purges—reduced changeover to 30 minutes, enabling economical batches of 500 pieces.

Key Points

- Setup time directly determines economic batch size

- Most setup time is waste—preparation, searching, adjusting, waiting

- Standardization of equipment and procedures speeds setup

- Setup reduction enables flexibility without sacrificing capacity

Common Misconceptions

Setup time is inherent to the equipment. Most setup time comes from how the changeover is organized, not equipment limitations. Significant reductions are often possible without equipment modification.

Setup reduction reduces capacity. While each setup takes time, shorter setups enable more changeovers without capacity loss. The flexibility gained often improves overall equipment effectiveness.