Common Cause Variation

Personalize This

Get insights for your role

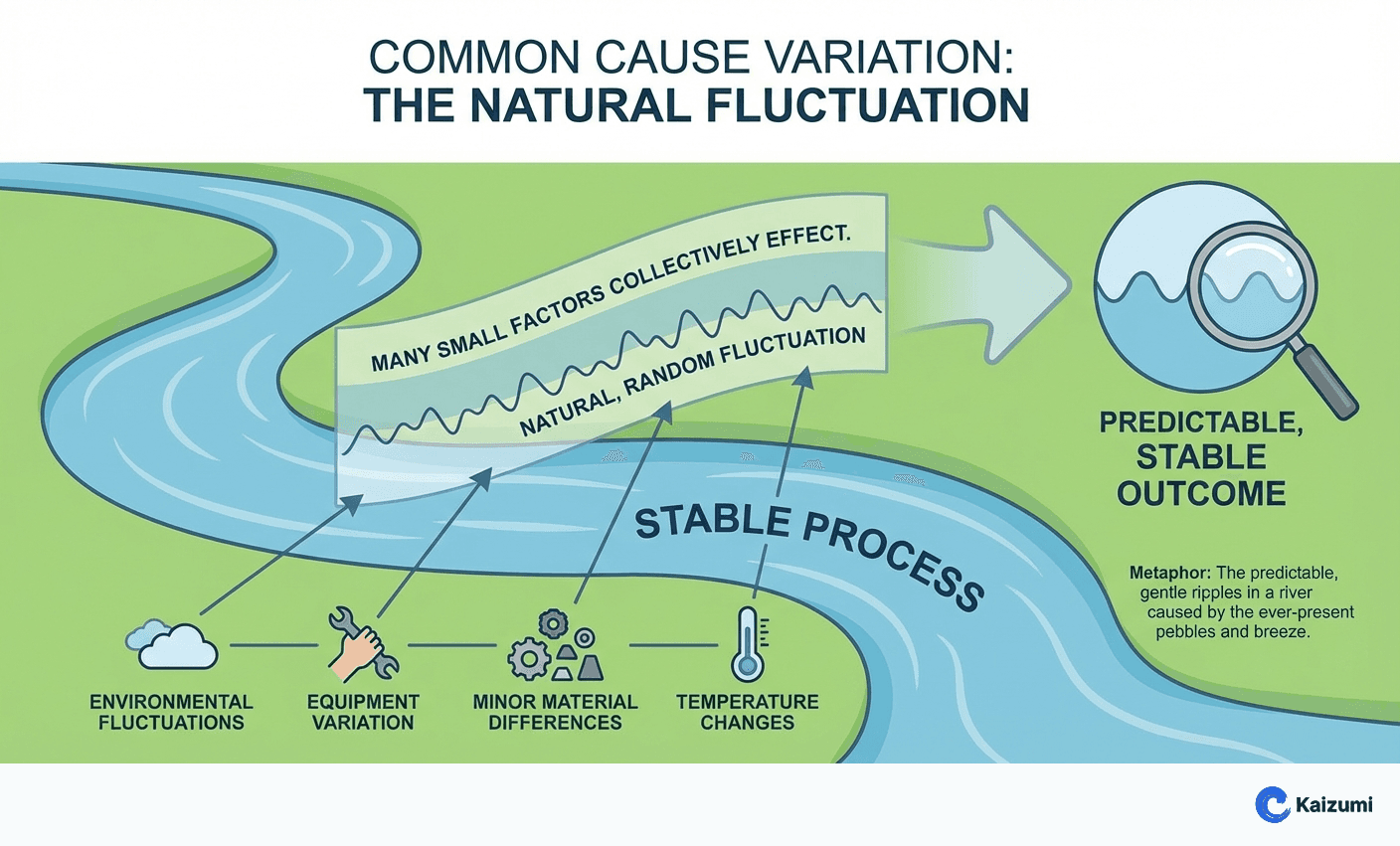

Common cause variation is the natural, inherent fluctuation in a process that occurs randomly and requires system-level changes to reduce.

Definition

Common cause variation is the natural, random fluctuation inherent to any process operating under stable conditions. It results from the collective effect of many small factors—minor material differences, environmental fluctuations, normal equipment variation—that are always present. Common cause variation is predictable in its range (though not in individual values) and can only be reduced through fundamental changes to the process system itself. On a control chart, common cause variation appears as random scatter within control limits.

Examples

A CNC machine produces parts with diameter variation of ±0.02mm around the target—consistent day after day, operator after operator. This is common cause variation from factors like thermal expansion, material hardness variation, and tool wear. Reducing it requires machine upgrade, better materials, or improved environmental control.

Key Points

- Common cause variation is inherent to the system and always present

- Appears as random scatter within control limits on control charts

- Cannot be reduced by investigating individual points—requires system changes

- Reacting to common cause as if it were special cause increases variation

Common Misconceptions

Common cause variation means the process is fine. A process can be stable (only common cause variation) while still producing unacceptable results. Stability is necessary but not sufficient for good performance. Capability assessment follows stability confirmation.

Any variation we can't explain is common cause. True common cause variation is random and patternless. Unexplained patterns or trends suggest unidentified special causes. Investigation may reveal assignable causes that were overlooked.