Just-in-Time

Personalize This

Get insights for your role

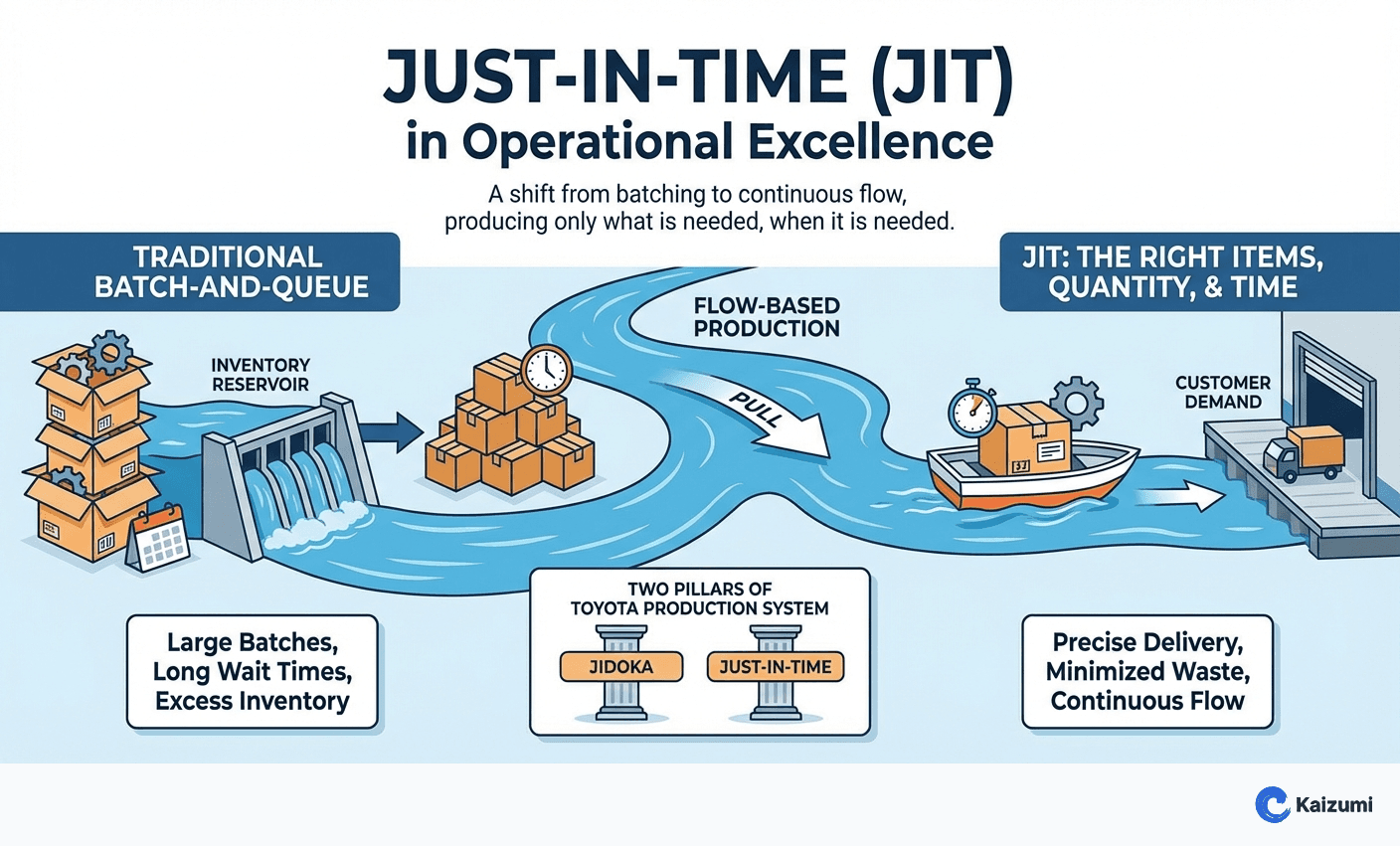

Just-in-Time (JIT) is a production strategy that produces only what is needed, when it is needed, in the amount needed.

Definition

Just-in-Time (JIT) is one of the two pillars of the Toyota Production System (alongside jidoka) and represents a fundamental shift from traditional batch-and-queue manufacturing to flow-based production. JIT means producing and delivering the right items, in the right quantity, at exactly the right time. Rather than building inventory "just in case" it might be needed, JIT systems build to actual demand, dramatically reducing waste from overproduction, inventory, and the problems that inventory hides. JIT requires exceptional process reliability, quality, and coordination because there is no buffer inventory to absorb variation.

Examples

An automotive assembly plant receives seats from a supplier in exact sequence, delivered to the line within two hours of installation. Each seat is built specifically for the vehicle it will be installed in, matching color, features, and options. This JIT system eliminates the warehouse space that batch delivery would require.

Key Points

- JIT is demand-driven, producing to actual customer need rather than forecast

- Requires stability, quality, and reliability—JIT exposes every problem

- Small lot sizes and frequent deliveries replace large batches and warehouses

- JIT applies to information flow as well as material flow

Common Misconceptions

JIT means zero inventory. JIT reduces inventory dramatically but doesn't eliminate it entirely. Strategic buffers exist where variation cannot be eliminated, and finished goods inventory may be needed to handle demand fluctuation.

JIT is risky because there's no safety stock. JIT actually reduces risk by making problems visible immediately rather than hiding them in inventory. High inventory often masks underlying problems that eventually cause bigger disruptions.