Lead Time

Personalize This

Get insights for your role

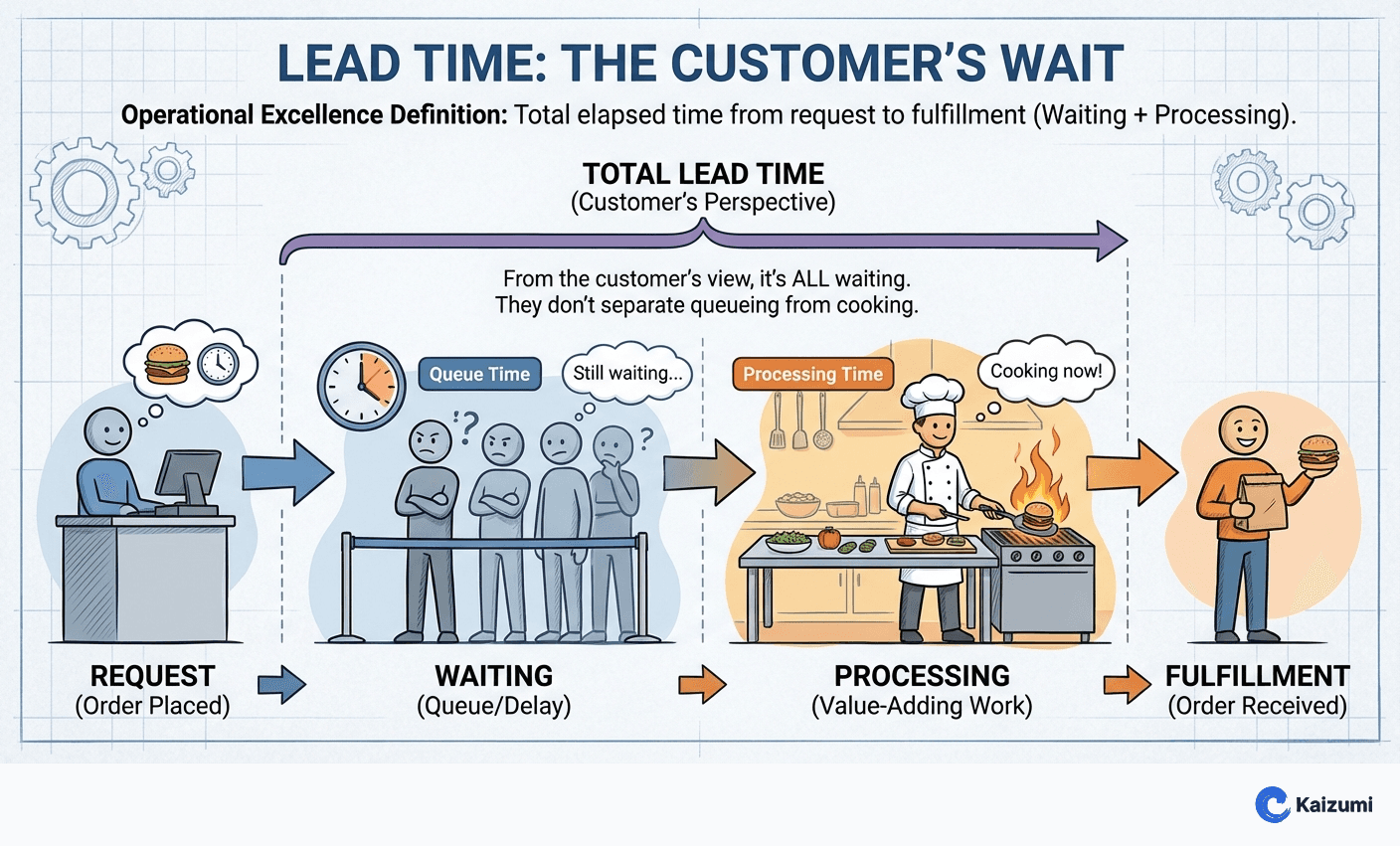

Lead time is the total elapsed time from when a request is made until it is fulfilled - the customer's experience of waiting.

Definition

Lead time is the total elapsed time from when a customer or downstream process makes a request until that request is fulfilled. It encompasses all waiting time plus all processing time. From the customer's perspective, lead time is how long they wait—they don't distinguish between processing and queue time. Lead time is a critical lean metric because it directly reflects customer experience and because it reveals the waste hidden in traditional processes. Most lead time is typically waiting, not processing.

Examples

A part requires 45 minutes of machining but has a three-week lead time. The 45 minutes is cycle time; the three weeks is lead time. The difference—nearly 100%—is waiting in queues, transportation, and batching. Lean improvement focuses on this gap.

Key Points

- Lead time is the customer-facing metric—what they experience

- Most lead time is typically waiting, not value-adding processing

- Reducing lead time requires addressing flow and eliminating waiting

- Lead time often reveals 95%+ non-value-adding time in traditional processes

Common Misconceptions

Reducing cycle time reduces lead time proportionally. If a 30-minute process has a 2-week lead time, making it 15 minutes barely affects the 2 weeks. Lead time reduction requires addressing waiting, batching, and flow—not just process speed.

Lead time and cycle time are interchangeable terms. These measure fundamentally different things. Cycle time is processing time for one item; lead time is total elapsed time including all waiting. The distinction matters enormously for improvement focus.