Out-of-Cycle Work

Personalize This

Get insights for your role

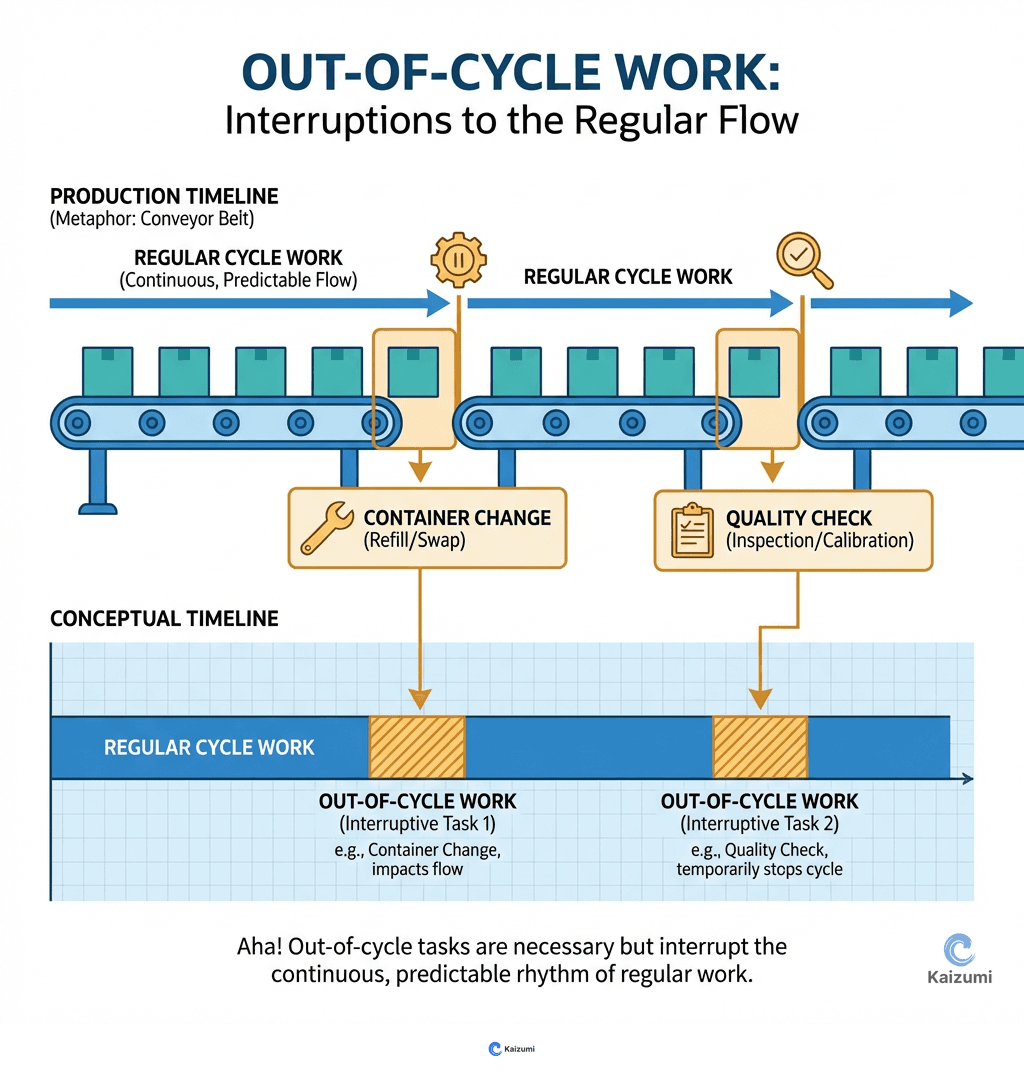

Out-of-cycle work is any task an operator must perform that doesn't occur every cycle, disrupting standard work rhythm and timing.

Definition

Out-of-cycle work is any task that doesn't occur every production cycle—activities like changing empty containers, retrieving new materials, periodic quality checks, equipment adjustments, or responding to abnormalities. While standard work defines what happens every cycle, out-of-cycle work interrupts that rhythm. These interruptions must be planned for in line balancing, or operators will periodically fall behind and struggle to catch up. Excessive out-of-cycle work makes cycle times unpredictable and destabilizes flow.

Examples

An assembly operator's standard work takes 55 seconds per cycle against a 60-second takt time—seemingly 5 seconds of slack. But every 10 cycles, they must change the parts bin (30 seconds), and every 20 cycles, perform a quality check (45 seconds). Without accounting for this out-of-cycle work, the operator falls behind unpredictably. Proper analysis averages the out-of-cycle time across cycles and adjusts workload accordingly.

Key Points

- Must be identified, timed, and included in workload calculations

- Can be reduced through better workplace organization and material presentation

- Should be smoothed—spreading out-of-cycle tasks rather than clustering them

- Often handled by team leaders or water spiders to protect operator cycle time

Common Misconceptions

Out-of-cycle work is waste to be eliminated. Some out-of-cycle work is necessary (quality checks, material replenishment). The goal is to minimize, standardize, and plan for it—not pretend it doesn't exist.

Cycle time analysis captures total work. Analysis often focuses on the repetitive cycle, missing the out-of-cycle burden. Complete work measurement must include both.