Pack-Out Quantity

Personalize This

Get insights for your role

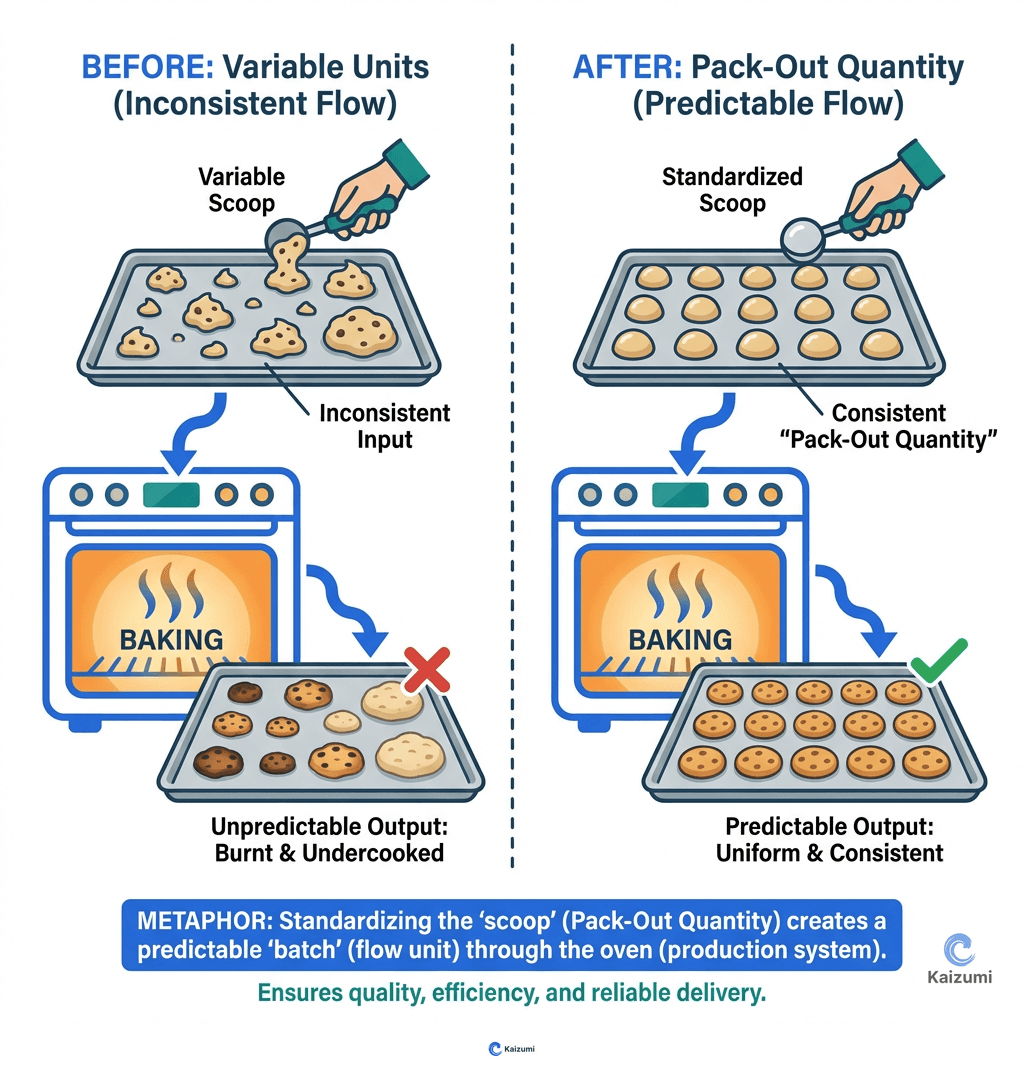

Pack-out quantity is the standard number of units packaged together for shipping or movement between processes.

Definition

Pack-out quantity is the standard number of units placed in a container, tray, or package for shipping to customers or movement between processes. This quantity becomes a fundamental unit of production planning, material handling, and scheduling. Pack-out quantity multiplied by takt time often equals pitch—the time increment for scheduling and material movement. Standardized pack-out quantities enable visual management (full container = correct quantity), simplify counting, and create consistent material handling loads.

Examples

An automotive supplier's pack-out quantity is 24 parts per returnable container, matching the customer's line-side requirement. Takt time is 2.5 minutes per part, so pitch is 60 minutes (24 × 2.5). Every 60 minutes, one container ships. Production schedules in container multiples, and material handlers know exactly what a full container represents.

Key Points

- Creates the fundamental unit for scheduling and material movement

- Enables visual management—full container equals standard quantity

- Should align with customer requirements and internal handling capabilities

- Forms the basis for pitch calculation (pack-out × takt = pitch)

Common Misconceptions

Larger pack-out quantities are more efficient. Larger quantities mean larger batches, more inventory, and less frequent replenishment. The right pack-out balances handling efficiency with flow requirements.

Pack-out quantity is determined by container availability. Containers should be selected to match the ideal pack-out quantity, not the reverse. Right-sized containers support flow; arbitrary containers force awkward quantities.