Perfection

Personalize This

Get insights for your role

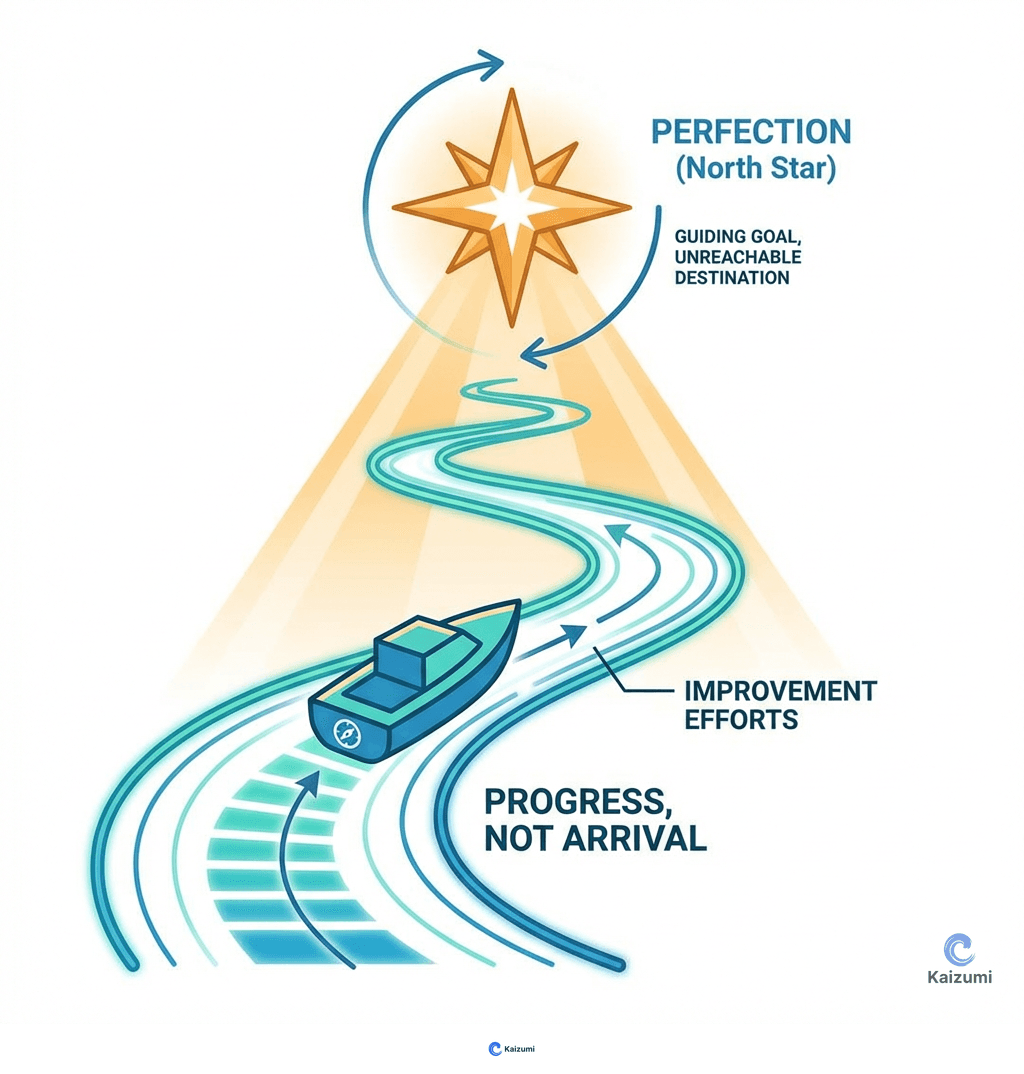

Perfection in lean thinking is the theoretical state of zero waste, instant response, and perfect quality—the guiding star for continuous improvement.

Definition

Perfection is one of the five principles of lean thinking (along with value, value stream, flow, and pull). Perfection represents the ideal state where every step creates value, nothing is wasted, products flow instantly from raw material to customer, quality is perfect, and customer needs are met exactly. Perfection is unattainable in practice—it's a theoretical limit. But pursuing perfection creates the mindset that no level of improvement is "good enough." Every waste that remains is a target for elimination. Perfection serves as lean's true north, providing direction even when the destination can never be reached.

Examples

A cell achieves 99% quality. The perfection mindset asks: "What would it take to reach 100%?" Not because 99% isn't good, but because the pursuit reveals improvement opportunities. The 1% defect rate, once acceptable, becomes the next target.

Key Points

- One of the five lean principles, providing direction for improvement

- Unattainable in practice but valuable as a mindset and guide

- Prevents satisfaction with current state, no matter how good

- Similar to "true north"—providing direction, not destination

Common Misconceptions

Perfection is an achievable goal. It's a direction, not a destination. The value is in pursuing perfection, not reaching it.

Pursuing perfection means nothing is ever good enough. Pursuing perfection drives improvement without requiring dissatisfaction with current state. Celebrate progress while continuing to pursue more.