Reliability Centered Maintenance

Personalize This

Get insights for your role

Reliability Centered Maintenance (RCM) is a systematic process for determining the most effective maintenance approach for each equipment failure mode.

Definition

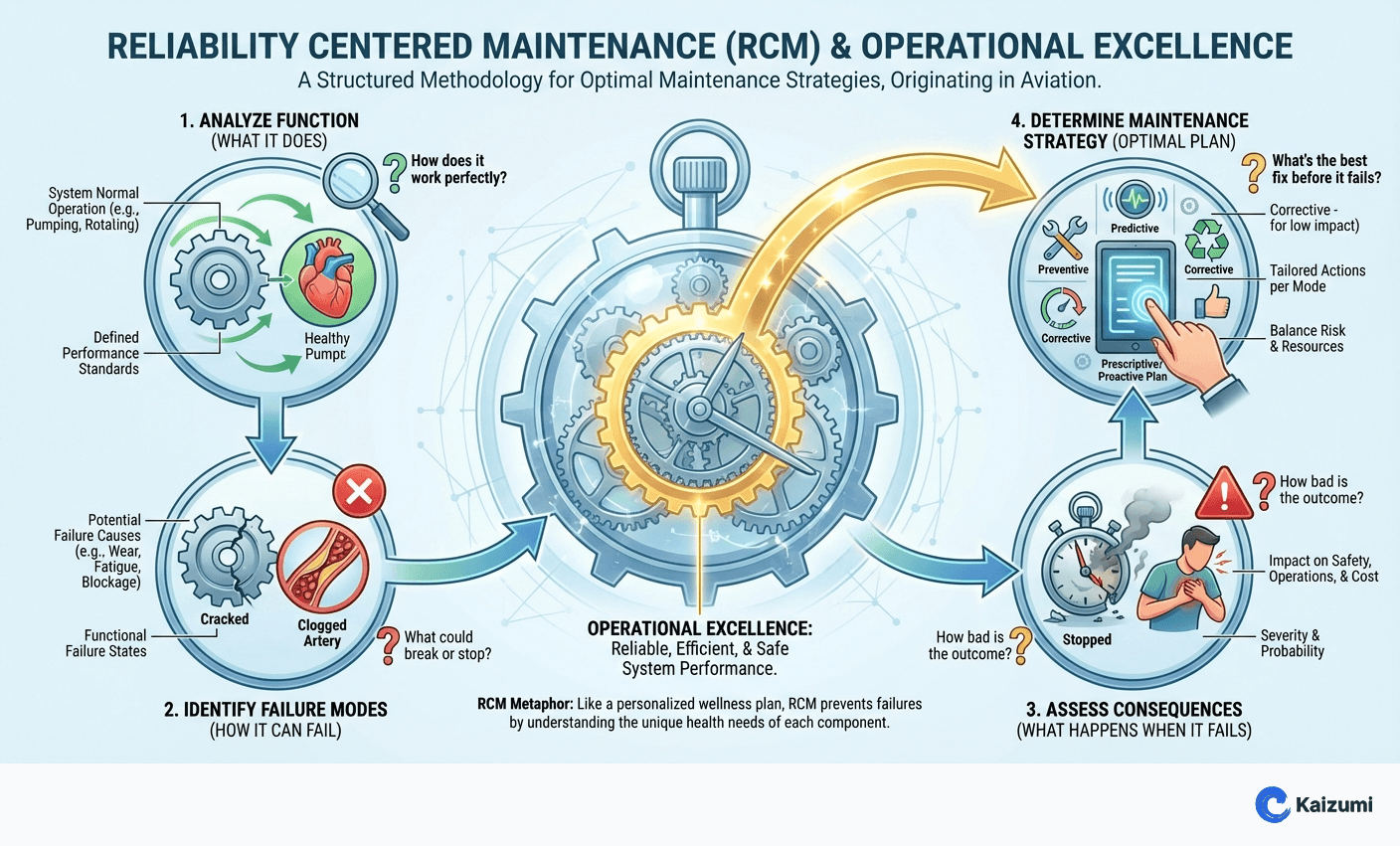

Reliability Centered Maintenance (RCM) is a structured methodology for determining the most appropriate maintenance strategy for each equipment failure mode. Originating in commercial aviation, RCM analyzes what each asset does (function), how it can fail (failure modes), what happens when it fails (effects), and what proactive tasks can prevent or mitigate failure. The result is tailored maintenance—preventive, predictive, or run-to-fail—matched to each failure mode's characteristics and consequences.

Examples

RCM analysis of a critical press revealed 15 failure modes. Three warranted predictive maintenance (bearing wear, hydraulic degradation), five warranted time-based preventive maintenance (filter replacement, lubrication), and seven were appropriately run-to-fail (low-criticality, unpredictable, cheap to replace). The optimized program reduced maintenance cost 20% while improving reliability.

Key Points

- Determines optimal maintenance strategy for each failure mode

- Options: preventive (time-based), predictive (condition-based), or run-to-fail

- Based on failure characteristics: detectability, predictability, consequences

- Originated in aviation, now applied across industries

Common Misconceptions

RCM means more preventive maintenance. RCM often reduces preventive maintenance by identifying tasks that don't prevent failure or address low-consequence failure modes. The goal is optimal maintenance, not maximum maintenance.

RCM is too complex for most organizations. Full RCM methodology can be intensive, but simplified versions apply the core logic—matching maintenance strategy to failure characteristics—without complete formal analysis.