Preventive Maintenance

Personalize This

Get insights for your role

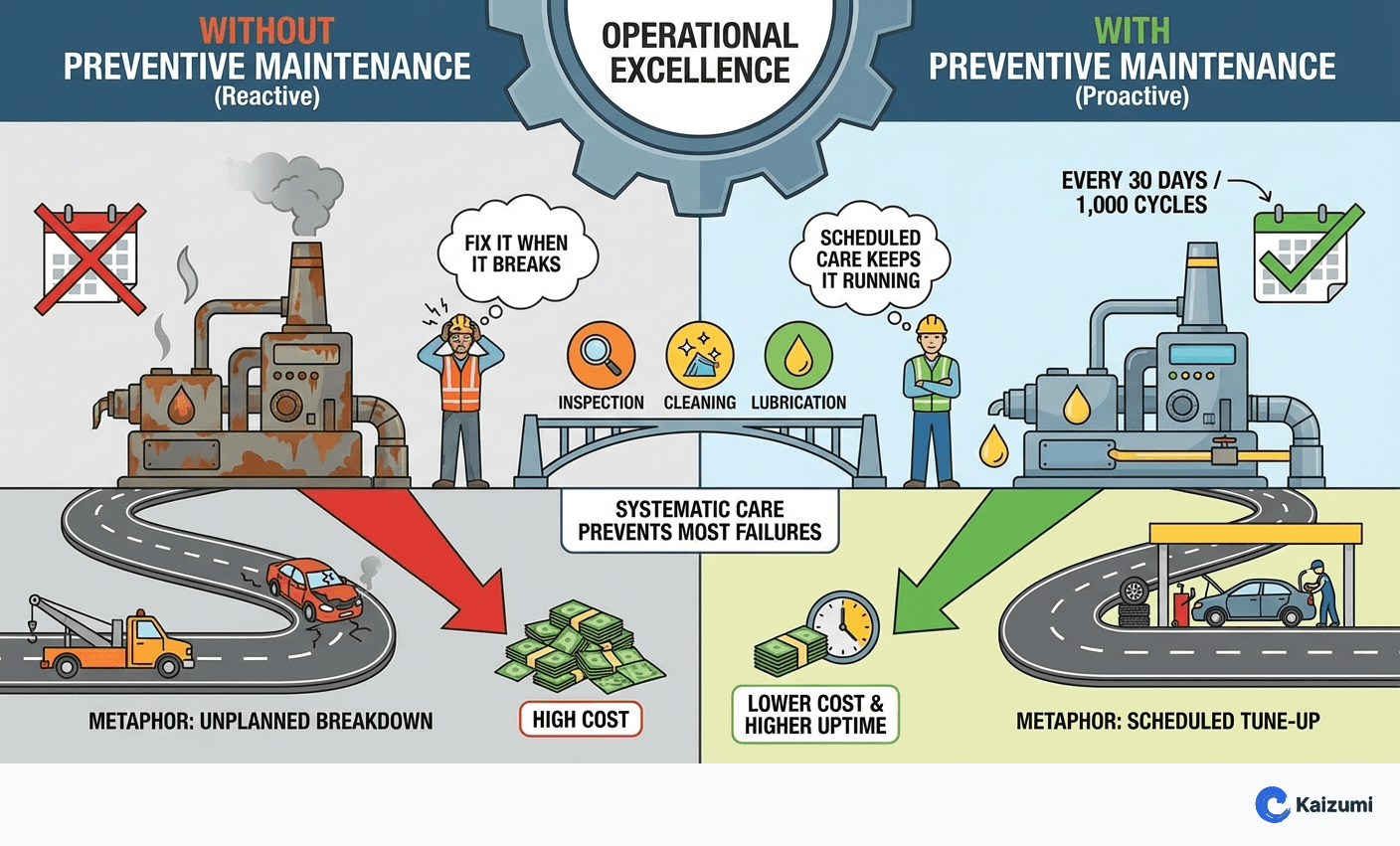

Preventive maintenance is scheduled, time-based or usage-based maintenance performed at regular intervals to prevent equipment failures.

Definition

Preventive maintenance (PM) is scheduled maintenance performed at predetermined intervals—either time-based (every 30 days) or usage-based (every 1,000 cycles)—regardless of equipment condition. The premise is that systematic care prevents most failures. PM activities include inspection, cleaning, lubrication, adjustment, and component replacement. While not as sophisticated as condition-based predictive maintenance, preventive maintenance is simpler to implement and effective for many failure modes where degradation follows predictable patterns.

Examples

A machine shop performs preventive maintenance on CNC machines every 250 operating hours: lubrication, filter replacement, alignment check, and belt inspection. This routine prevents 80% of the breakdowns that occurred before PM implementation.

Key Points

- Scheduled based on time intervals or usage counts

- Performed regardless of apparent equipment condition

- Simpler than predictive maintenance but may over- or under-maintain

- Effective when failure patterns are predictable and consistent

Common Misconceptions

Preventive maintenance prevents all failures. PM addresses time-dependent and wear-out failures but not random failures or condition-dependent degradation. Some components fail unpredictably regardless of maintenance schedule.

More frequent PM is always better. Over-maintenance wastes resources and can introduce failures through unnecessary intervention (infant mortality). Optimal PM frequency balances prevention benefit against intervention cost and risk.