Rolled Throughput Yield

Personalize This

Get insights for your role

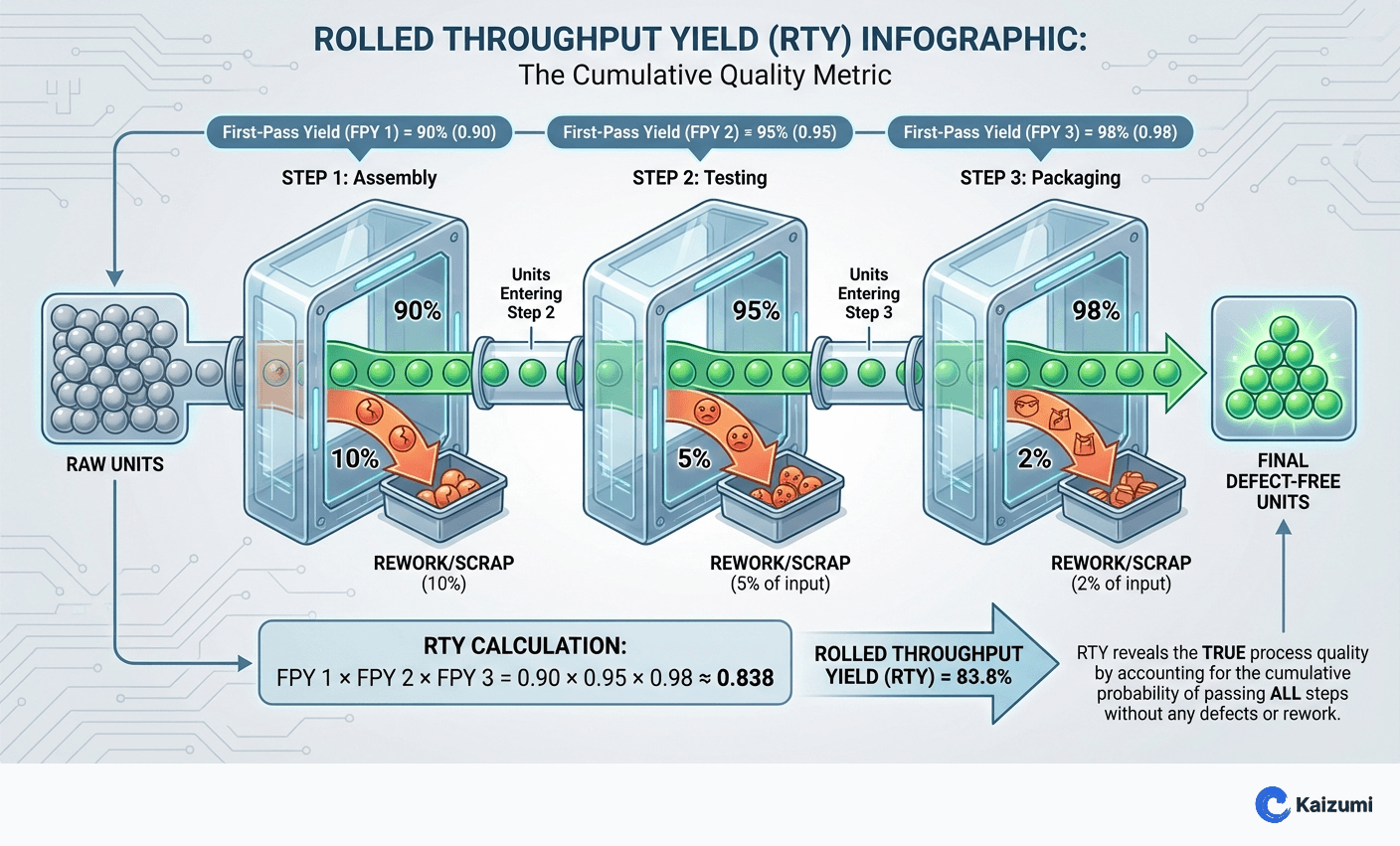

Rolled Throughput Yield (RTY) measures the probability that a unit passes through an entire process without any defects or rework at any step.

Definition

Rolled Throughput Yield (RTY) is a metric that measures the probability of a unit passing through an entire multi-step process without any defects or rework. It is calculated by multiplying the first-pass yields of each process step. RTY reveals the true process quality by accounting for defects that occur but get corrected before final inspection—exposing the "hidden factory" of rework that traditional final yield metrics miss. A process with 95% yield at each of 10 steps has RTY of only 60%.

Examples

A five-step assembly process showed 99% final yield—impressive until RTY analysis. Step yields were: 95%, 98%, 97%, 96%, 99%. RTY = 0.95 × 0.98 × 0.97 × 0.96 × 0.99 = 85.9%. The "hidden factory" of rework affected 14% of units, consuming resources that final yield metrics hid.

Key Points

- RTY = Product of first-pass yields at each step (FPY₁ × FPY₂ × ... × FPYₙ)

- Reveals hidden factory—rework and corrections that don't appear in final yield

- Long processes with many steps compound quality losses dramatically

- More accurate reflection of process quality than final inspection yield

Common Misconceptions

High final yield means the process is good. Final yield only captures defects that escape to the customer. RTY captures all defects including those caught and corrected internally. A process can have high final yield but terrible RTY due to extensive rework.

RTY applies only to manufacturing. Any multi-step process—service, administrative, healthcare—benefits from RTY analysis. If steps can have errors that get corrected downstream, RTY reveals the true quality picture.