SIPOC

Personalize This

Get insights for your role

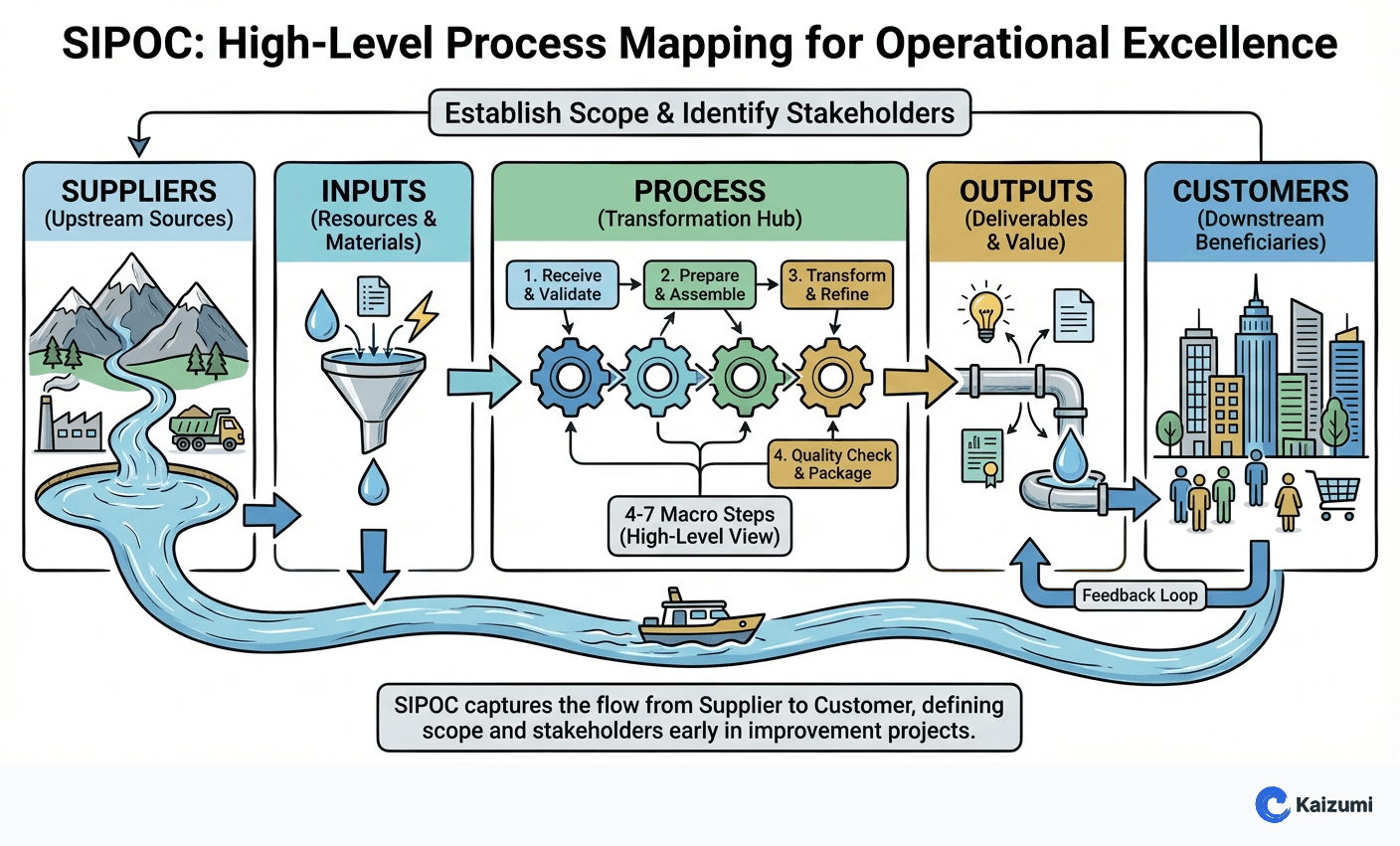

SIPOC is a high-level process map showing Suppliers, Inputs, Process, Outputs, and Customers to define project scope and stakeholders.

Definition

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) is a high-level process mapping tool used early in improvement projects to establish scope and identify stakeholders. The diagram captures what suppliers provide (inputs), the major process steps at a macro level (typically 4-7 steps), what the process produces (outputs), and who receives those outputs (customers). SIPOC creates shared understanding of process boundaries before detailed analysis begins, preventing scope creep and ensuring all stakeholders are identified.

Examples

Before a quality improvement project, the team created a SIPOC. Suppliers: raw material vendors, tooling suppliers. Inputs: steel, specifications, tooling. Process: receive, machine, inspect, ship. Outputs: finished parts, documentation. Customers: assembly plant, quality records. This clarified that assembly plant requirements should drive the project.

Key Points

- Create SIPOC in Define phase before detailed process mapping

- Limit process column to 4-7 high-level steps

- Identify both internal and external customers

- Use to define project boundaries and prevent scope creep

Common Misconceptions

SIPOC is a detailed process map. SIPOC is intentionally high-level to show the big picture. Detailed process maps come later in the Measure phase. Adding detail to SIPOC defeats its purpose of establishing clear boundaries.

SIPOC needs to include all process details. A SIPOC with 20 process steps is too detailed. Keep it at 4-7 macro steps that anyone could understand. The discipline of keeping it simple forces clarity about what's really in scope.