Autonomous Maintenance

Personalize This

Get insights for your role

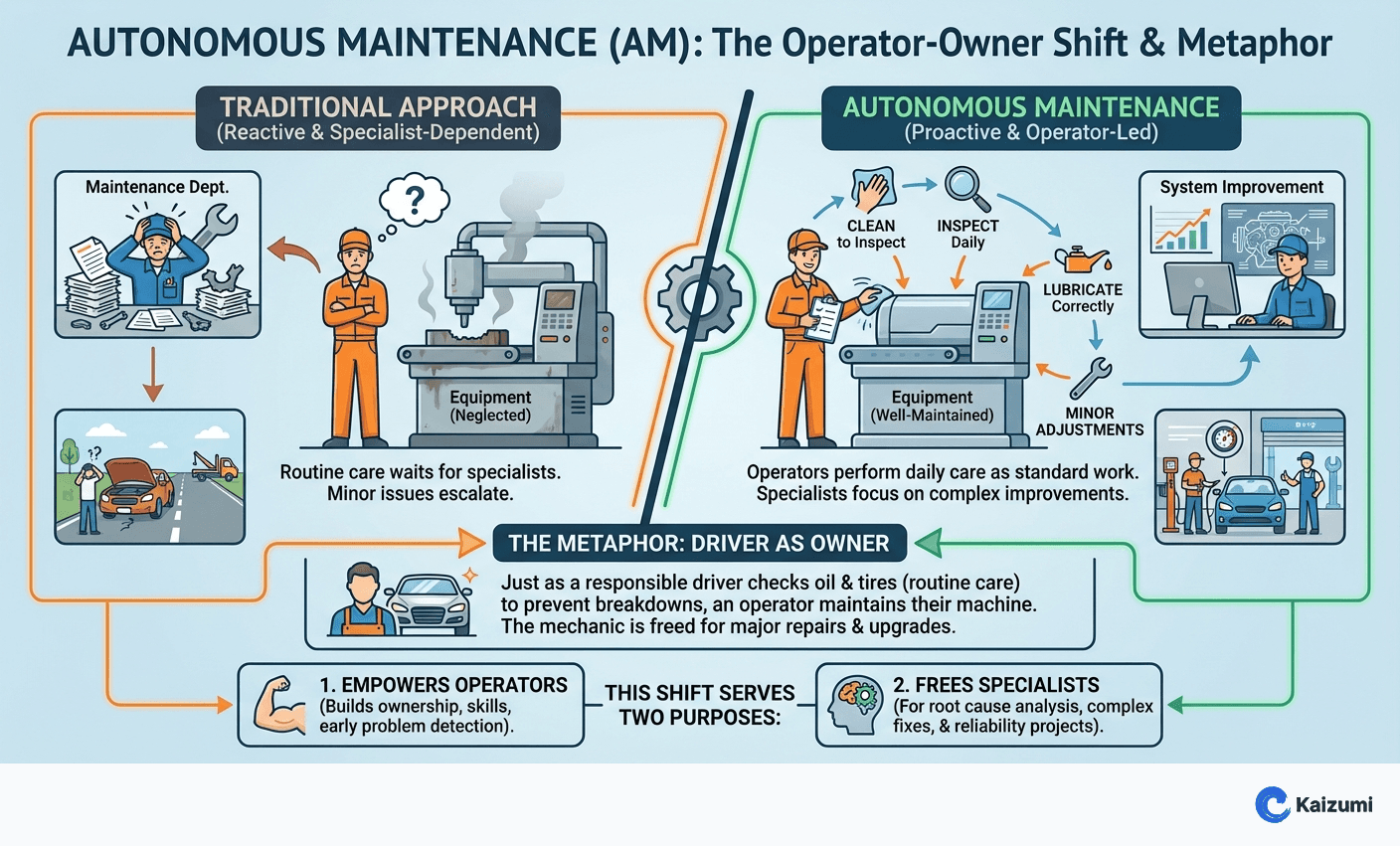

Autonomous maintenance empowers equipment operators to perform routine maintenance tasks like cleaning, inspection, and lubrication on their own machines.

Definition

Autonomous maintenance is a TPM pillar that transfers routine equipment care from maintenance specialists to machine operators. Operators learn to clean, inspect, lubricate, and make minor adjustments to their equipment—tasks they perform daily as part of standard work. This shift serves two purposes: it frees maintenance technicians for complex work while building operator knowledge of equipment behavior. Operators who clean and inspect their machines daily detect abnormalities early, preventing breakdowns before they occur.

Examples

Assembly line operators learned autonomous maintenance in seven steps over 12 months. They now perform daily cleaning and inspection, check lubrication levels, and identify abnormalities for maintenance attention. Unplanned breakdowns dropped 65%, and operators report feeling more ownership of "their" machines.

Key Points

- Transfers routine care from maintenance to operators

- Seven-step implementation: initial cleaning through full autonomous capability

- Operators become "equipment sensors" detecting abnormalities early

- Frees maintenance resources for complex, value-added work

Common Misconceptions

Autonomous maintenance dumps work on operators. Properly implemented, AM transfers tasks operators can do better (daily presence at equipment) while relieving them of non-value-added waiting for maintenance. The goal is empowerment, not burden shifting.

Operators don't have technical skills for maintenance. Autonomous maintenance tasks match operator capabilities: cleaning, inspecting, basic adjustments. Complex repairs remain with technicians. The seven-step progression builds skills systematically.