Buffer Stock

Personalize This

Get insights for your role

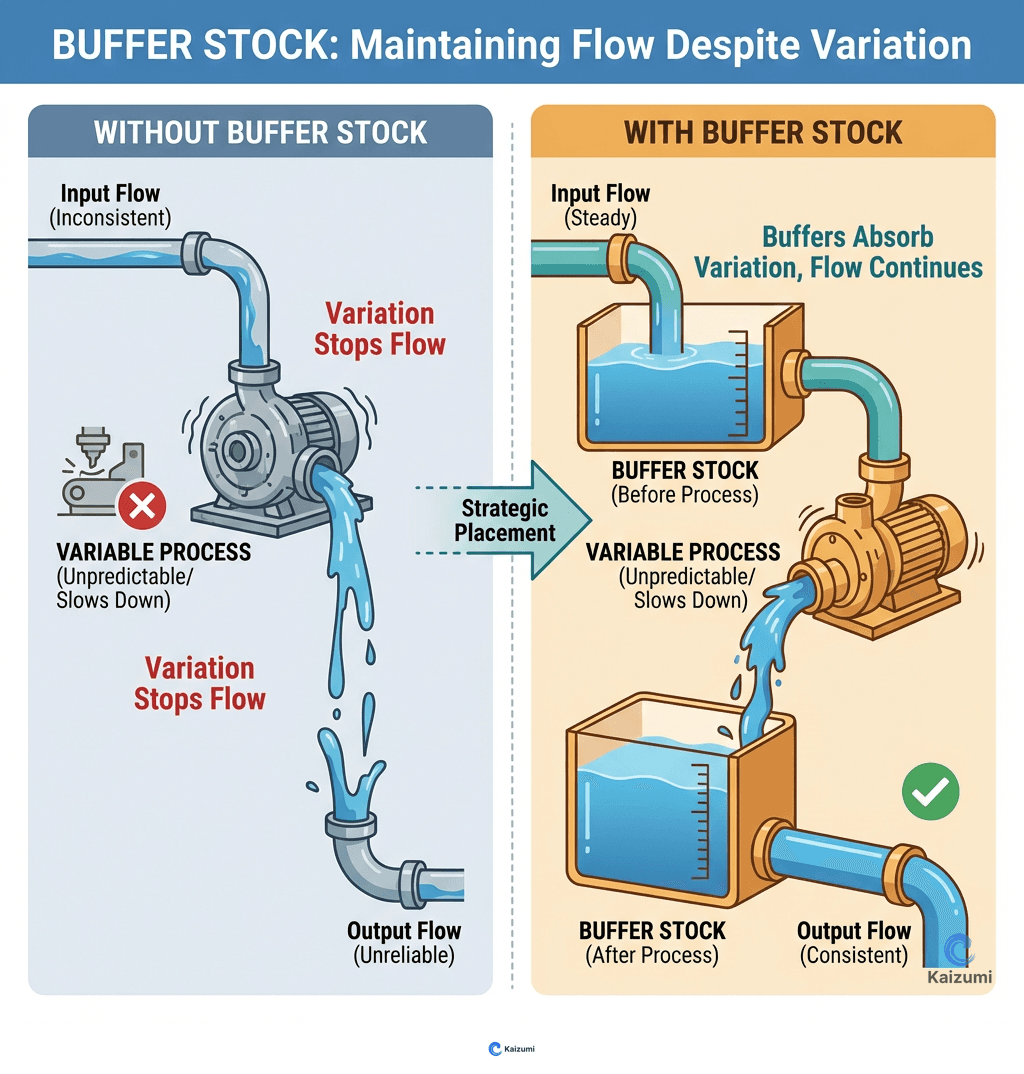

Buffer stock is inventory held to protect against variability in production or demand, distinct from safety stock for supply variation.

Definition

Buffer stock is inventory strategically placed to absorb variability in production processes or customer demand, enabling downstream operations to continue despite upstream disruptions. Unlike safety stock (which protects against supply variability), buffer stock protects against process variability—equipment breakdowns, quality issues, or demand fluctuations. In Theory of Constraints, buffer stock before constraints protects against starvation; in lean systems, buffer stock exists in supermarkets to absorb demand variation. Buffer stock is a necessary compromise when variability cannot yet be eliminated.

Examples

A machining center has 85% uptime due to periodic breakdowns. Buffer stock equivalent to 3 hours of production is maintained downstream, allowing assembly to continue during typical repair times. As machine reliability improves, buffer stock is reduced proportionally.

Key Points

- Sized based on variability magnitude and acceptable stock-out risk

- Should be systematically reduced as variability is eliminated

- Location matters—buffer should protect the point of highest impact

- Different from safety stock, which protects against supply variability

Common Misconceptions

Buffer stock is waste. Ideally yes, but it's necessary waste when variability exists. The goal is to reduce the need for buffer by improving stability, not to eliminate buffer while variability remains.

Bigger buffer is safer. Excess buffer hides problems and consumes resources. Buffer should be sized to variability—enough to protect, not more.