U-Shaped Cell

Personalize This

Get insights for your role

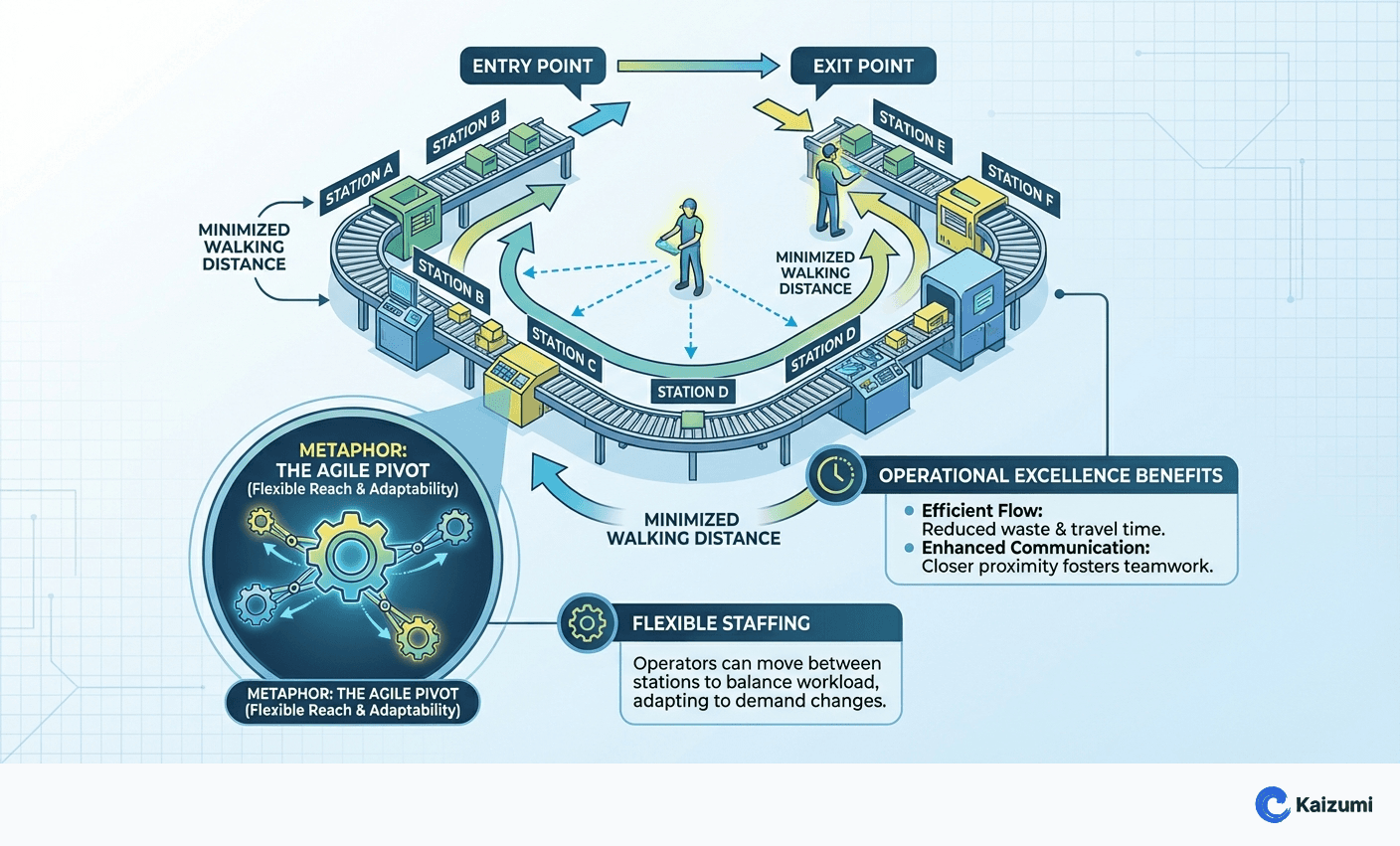

A U-shaped cell arranges equipment in a U configuration, minimizing walking distance and enabling flexible staffing.

Definition

A U-shaped cell arranges equipment and workstations in a U configuration where the entry and exit points are close together. This layout minimizes walking distance because operators working in the center of the U can access multiple stations with minimal movement. U-cells also enable flexible staffing—depending on takt time, one operator might run all stations in the U, or multiple operators might share the work. This flexibility to adjust staffing based on demand is a key advantage over straight-line layouts.

Examples

An assembly cell arranged in a U allows one operator to complete all seven assembly steps by walking in a small circuit. When demand increases and takt time decreases, two operators can share the U, each handling part of the sequence. The layout flexes with demand.

Key Points

- Entry and exit at the same point minimizes travel and enables visual control

- U-cells enable flexible staffing—one operator can work all stations or multiple can share

- The layout supports one-piece flow by keeping stations close together

- Material flow is typically on the outside, operators work on the inside of the U

Common Misconceptions

U-cells require exactly one operator. The U shape accommodates variable staffing—one operator when demand is low, multiple when high. This flexibility is a key advantage.

Any U-shaped arrangement is a U-cell. True U-cells support flow—equipment is arranged in process sequence, not randomly. The U shape alone doesn't create the benefits; sequence and flow do.