Flow Production

Personalize This

Get insights for your role

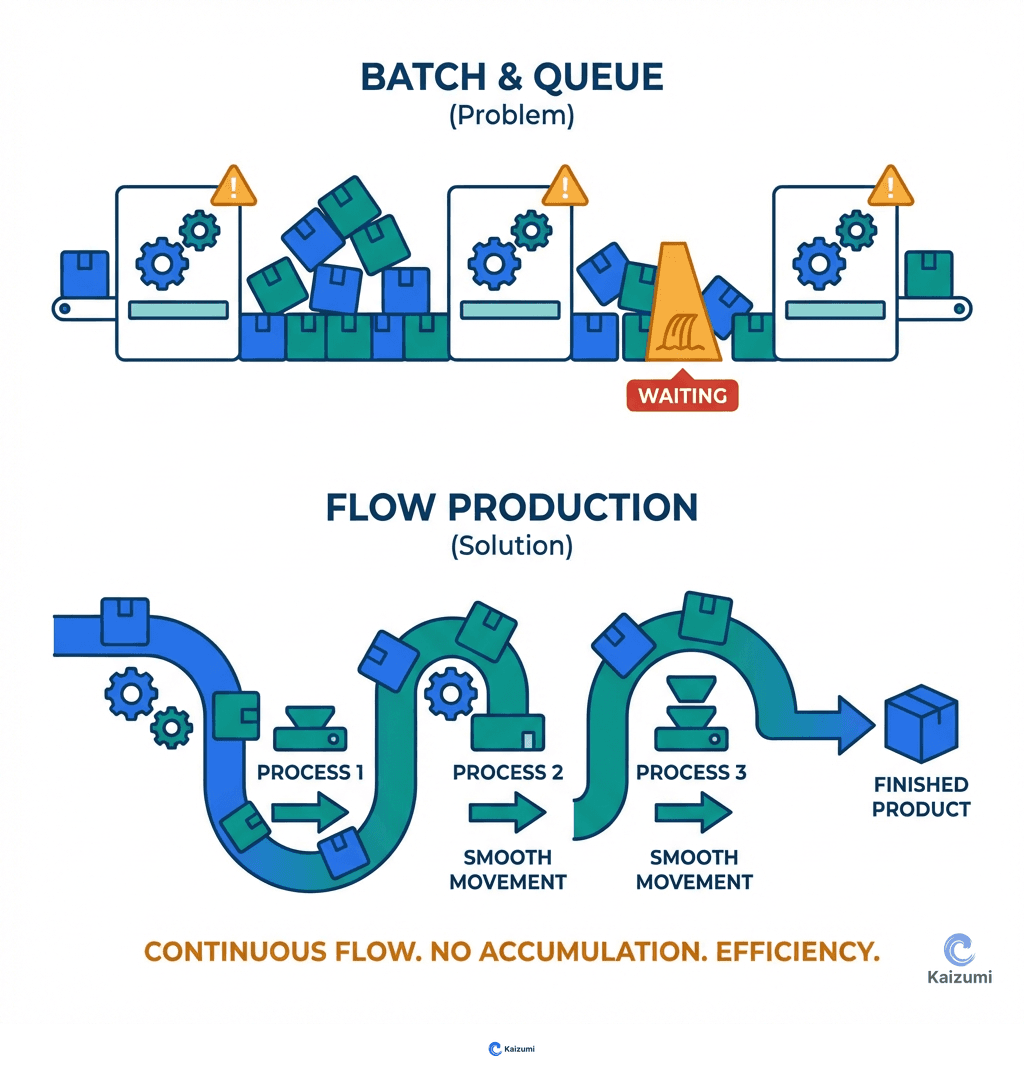

Flow production is a manufacturing method where products move continuously through processes with minimal waiting or batch accumulation.

Definition

Flow production is a manufacturing approach where products move continuously from one process to the next without waiting in queues between operations. Unlike batch-and-queue production where large lots accumulate between departments, flow production connects processes so that items move as soon as they're complete—ideally one piece at a time. This dramatically reduces lead time, work-in-process inventory, and quality problems while making inefficiencies immediately visible. Flow production requires balanced processes, reliable equipment, and flexible workers.

Examples

A furniture manufacturer converted from batch production to flow production. Instead of cutting all pieces, then sanding all pieces, then assembling all pieces, they created cells where one chair flows through cutting, sanding, and assembly in sequence. Lead time dropped from 3 weeks to 2 days, and defects were caught immediately at the next operation.

Key Points

- Flow exposes problems immediately—there's no inventory to hide behind

- Requires process stability, quality at the source, and balanced work content

- Lead time approaches actual processing time, eliminating wait time

- Creates a sense of urgency and immediate feedback

Common Misconceptions

Flow means everything moves at the same speed. Flow means no unnecessary waiting—but processes with different cycle times can still flow using small buffers or flexible staffing.

Flow is only for high-volume production. Flow principles apply to any repeating process. Even low-volume operations benefit from reducing wait time between steps.