Batch-and-Queue

Personalize This

Get insights for your role

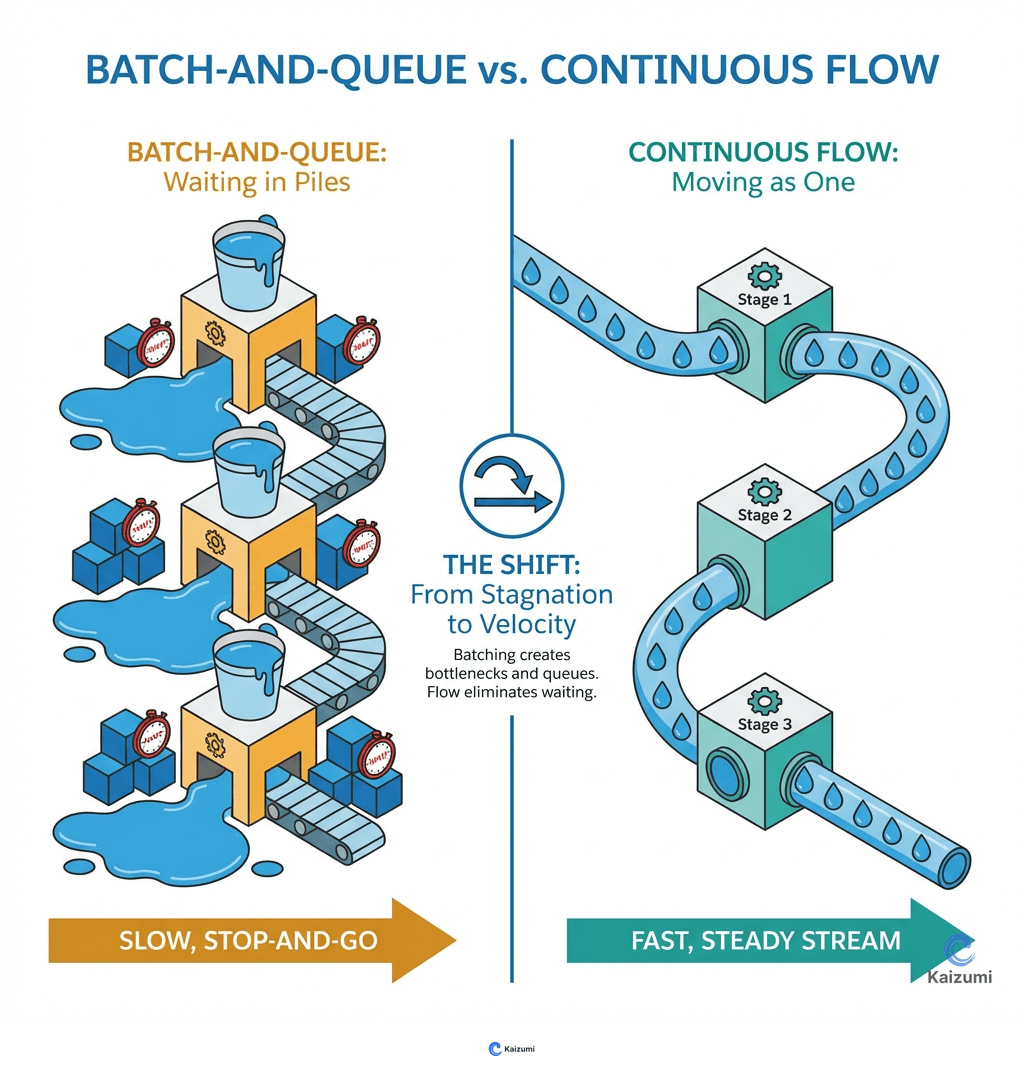

Batch-and-queue is a traditional production method where items are processed in large batches with waiting time between process steps.

Definition

Batch-and-queue is the traditional approach to production where work is processed in large batches, with each batch waiting in queue between process steps. A batch of 100 parts might be machined, then wait for the drilling department, then wait for assembly, then wait for inspection. While each process may appear efficient when measured in isolation, the system creates massive lead times, high inventory, hidden quality problems, and delayed feedback. Lean production aims to replace batch-and-queue with continuous flow, where items move one at a time through connected processes.

Examples

A machine shop processed orders in weekly batches: Monday cutting, Tuesday drilling, Wednesday grinding, Thursday assembly, Friday shipping. A simple part that required 15 minutes of actual work had a 5-day lead time. Converting to one-piece flow reduced lead time to 4 hours.

Key Points

- Batch-and-queue maximizes local efficiency at the expense of system efficiency

- Lead time = processing time + waiting time; batching inflates waiting time

- Large batches hide defects—problems aren't discovered until the entire batch is processed

- Converting to flow requires reducing changeover times and balancing processes

Common Misconceptions

Batching reduces costs through economies of scale. This ignores the cost of inventory, quality problems, expediting, and long lead times. Total system cost is usually higher with batching.

Some processes require batching. Some truly do (furnaces, chemical reactors), but many "requirements" are actually changeover problems in disguise. If changeover could be reduced, smaller batches would become feasible.