Milk Run

Personalize This

Get insights for your role

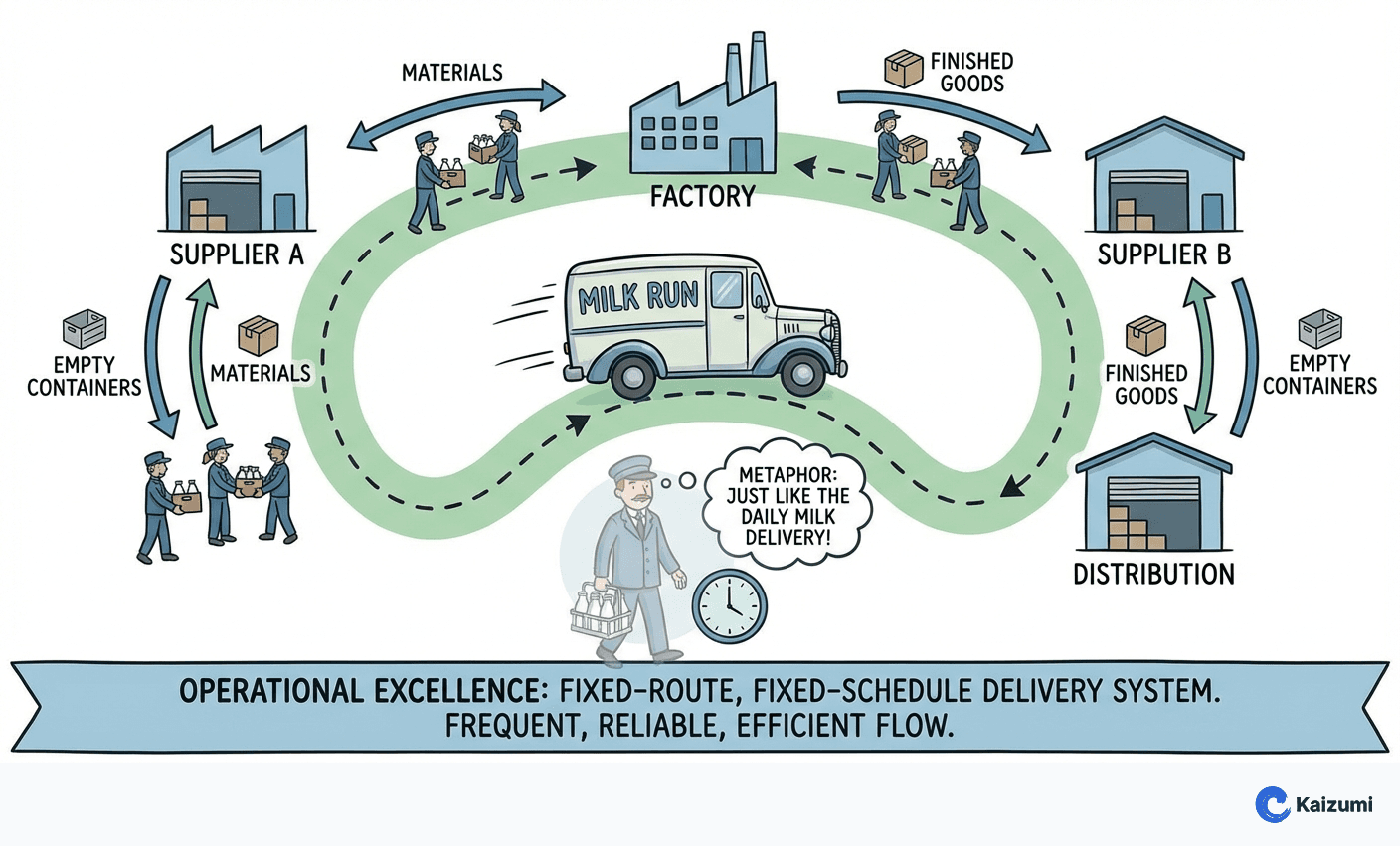

A milk run is a fixed-route delivery system that picks up and delivers materials on a regular schedule, like traditional milk delivery.

Definition

A milk run is a fixed-route, fixed-schedule material delivery system where a vehicle or material handler follows a predetermined route, stopping at each location to deliver materials and pick up empty containers or finished goods. Named after traditional milk delivery routes, milk runs enable frequent small deliveries rather than large infrequent batches. This supports just-in-time by reducing inventory at point of use while ensuring reliable supply. Milk runs work for external supplier deliveries and internal material movement.

Examples

A supplier milk run picks up from four suppliers each morning. The truck follows a fixed route, collecting small quantities from each supplier. The factory receives four daily deliveries of smaller quantities rather than four weekly deliveries of large batches, reducing inventory and improving freshness.

Key Points

- Fixed routes and schedules enable smaller, more frequent deliveries

- Pick up empty containers and kanban while delivering full ones

- Supports just-in-time by reducing inventory at consumption point

- Works for both external supplier delivery and internal material movement

Common Misconceptions

Milk runs increase transportation cost. While vehicle utilization per trip may be lower, total system cost often decreases due to reduced inventory, less expediting, and better production flow. The holistic system view matters.

Milk runs are only for manufacturing. Any operation with multiple pickup/delivery points benefits from route optimization and scheduled frequency—offices, hospitals, service operations.