Paced Withdrawal

Personalize This

Get insights for your role

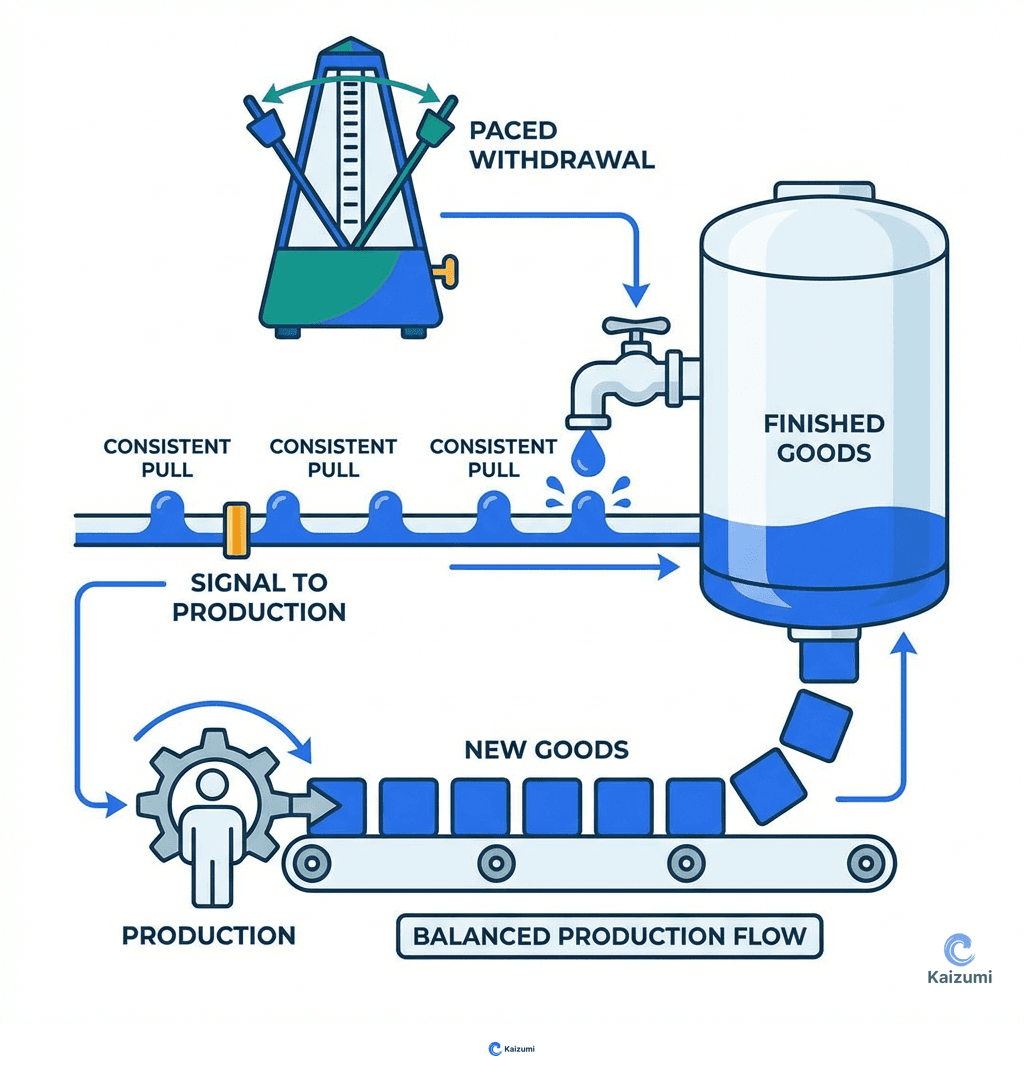

Paced withdrawal is the scheduled removal of finished goods at fixed intervals to create consistent demand signals upstream.

Definition

Paced withdrawal is the practice of removing finished goods or work-in-process at fixed time intervals rather than random or batch-triggered times. For example, collecting output from a work area every 30 minutes regardless of quantity creates a predictable rhythm. This consistent pacing provides regular feedback on production status (did we make the expected amount?), levels demand signals to upstream processes, and creates the heartbeat for the production system. Paced withdrawal is often synchronized with pitch—a multiple of takt time used to time material movement.

Examples

A shipping dock collects finished goods from the final assembly supermarket every 30 minutes. This paced withdrawal creates consistent demand signals: if the supermarket isn't replenished, the 30-minute pickup reveals a production problem within 30 minutes. Unpaced withdrawal might not reveal problems until end-of-shift counting.

Key Points

- Creates a regular heartbeat that makes abnormalities visible

- Withdrawal frequency determines how quickly problems surface

- Should be synchronized with production pitch for consistency

- Enables level scheduling and reduces demand amplification

Common Misconceptions

Pick up when full is more efficient. Random withdrawal hides production variability. If a container fills early, we don't know if we're ahead; if it fills late, we don't know until we notice it's not full. Paced withdrawal reveals status immediately.

Smaller intervals are always better. Very frequent withdrawal may not provide enough time to respond to problems before the next check. The interval should balance rapid feedback with practical response time.