Push System

Personalize This

Get insights for your role

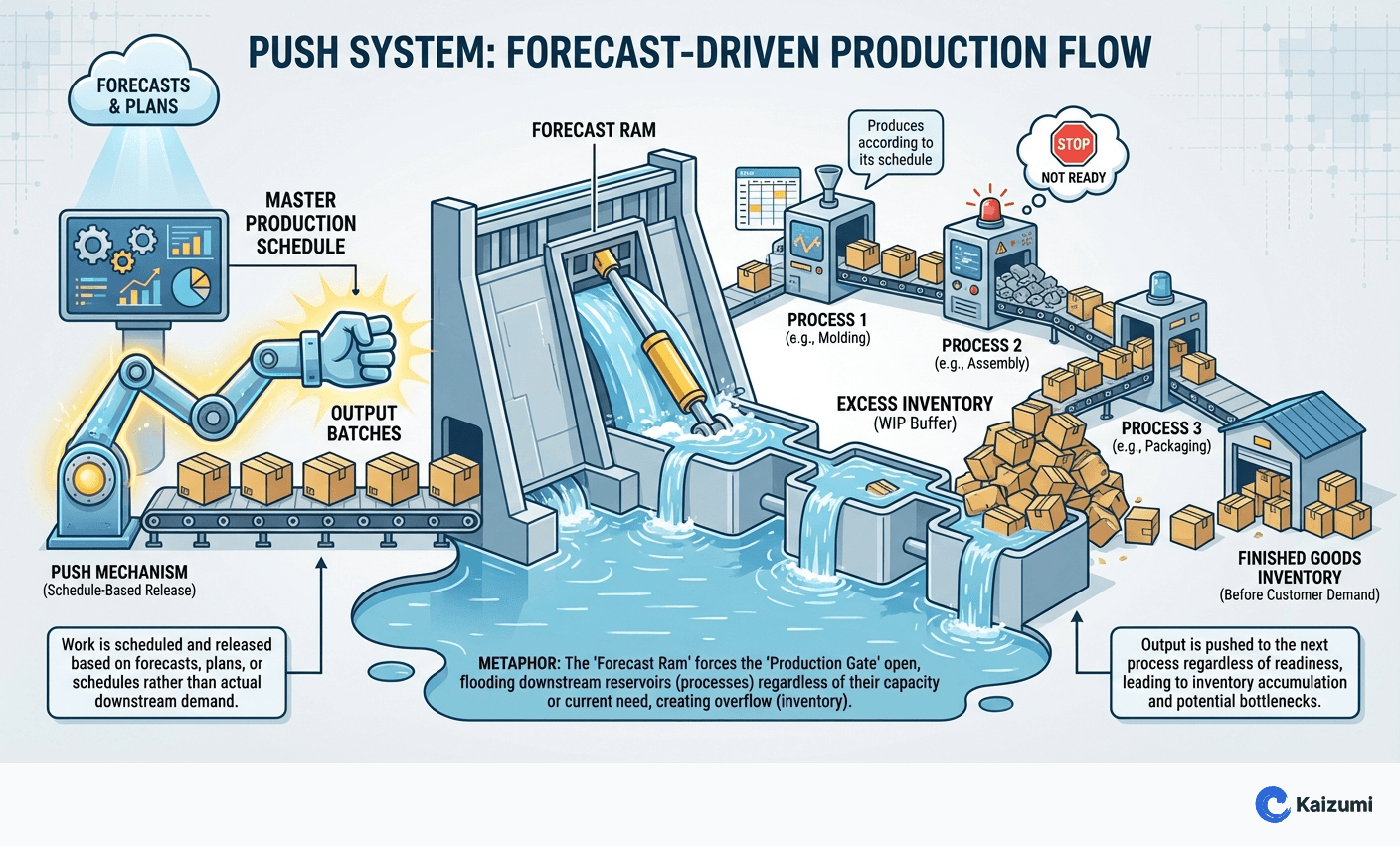

A push system produces based on forecasts and schedules, pushing work downstream regardless of actual demand.

Definition

A push system is a production control approach where work is scheduled and released based on forecasts, plans, or schedules rather than actual downstream demand. Each process produces according to its schedule and pushes output to the next process regardless of whether that process is ready to use it. Push systems typically result in inventory accumulation between processes, longer lead times, and overproduction—producing goods before they're needed or in quantities exceeding demand. While push systems are traditional and widespread, lean thinking generally favors pull systems for their inherent overproduction prevention.

Examples

A traditional factory schedules each department independently based on monthly forecasts. Stamping runs large batches to achieve efficiency, pushing parts to welding whether needed or not. Welding accumulates inventory waiting to be processed, then pushes to assembly. The result: weeks of work-in-process inventory, long lead times, and frequent expediting when the wrong items were produced.

Key Points

- Push systems disconnect production from consumption, enabling overproduction

- Inventory accumulates at each handoff point, extending lead times

- Push systems require accurate forecasts to avoid producing the wrong items

- "Keep everyone busy" thinking often drives push behavior even when demand is absent

Common Misconceptions

Push systems are always wrong. Some situations genuinely require push—long lead time items that must be forecast, seasonal production for peak demand, or processes with severe constraints on frequency. The issue is defaulting to push when pull would work better.

Push systems are more efficient because of larger batches. The apparent efficiency of large batches ignores the waste in the system—inventory carrying costs, obsolescence, quality issues from delayed feedback, and the expediting required when forecasts miss actual demand.