Quality Maintenance

Personalize This

Get insights for your role

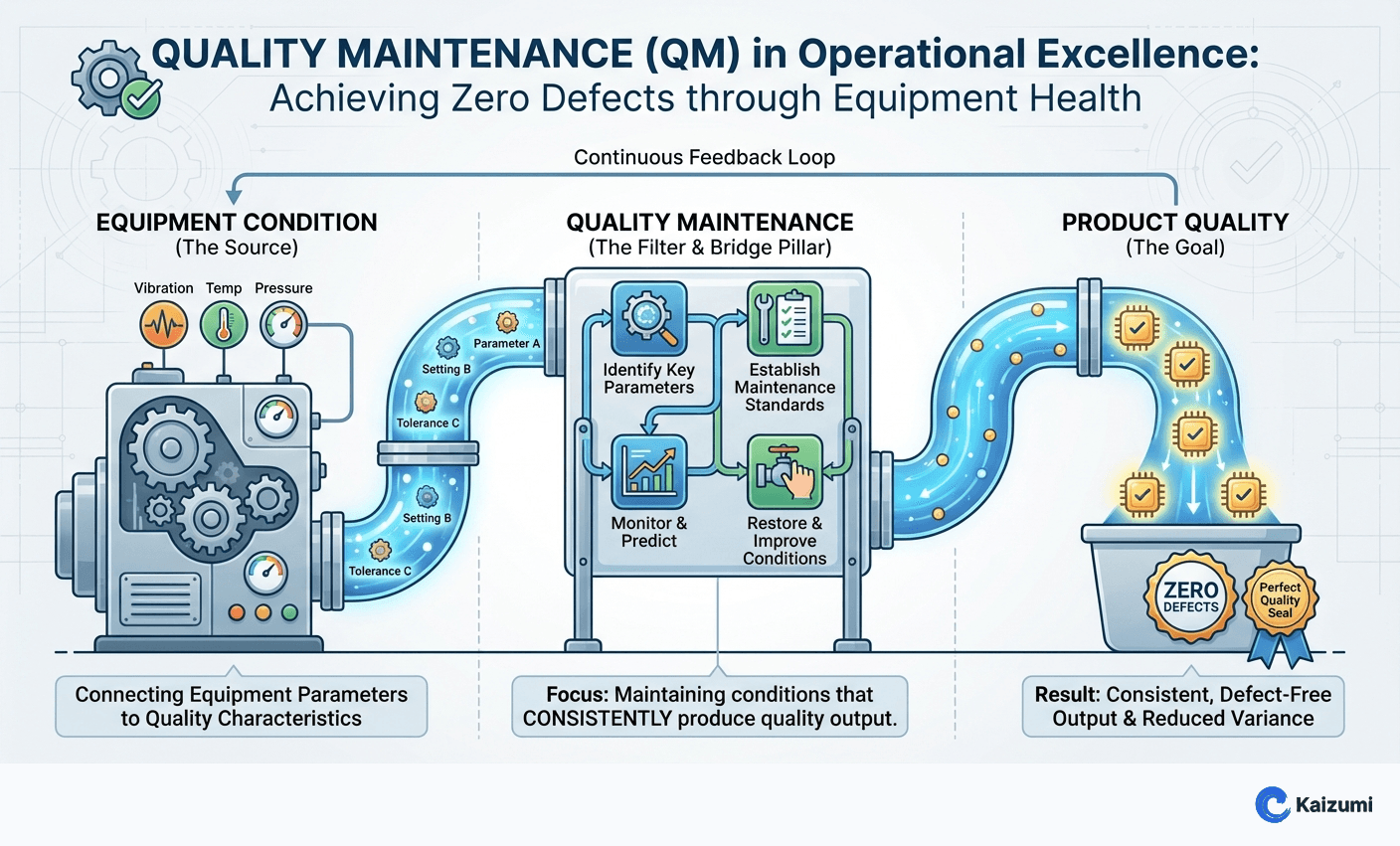

Quality maintenance is the TPM pillar focused on maintaining equipment conditions that produce zero-defect output through equipment precision and stability.

Definition

Quality maintenance is the TPM pillar focused on achieving zero defects through maintaining equipment conditions that consistently produce quality output. It connects equipment condition to product quality—identifying which equipment parameters affect quality characteristics and establishing maintenance practices to keep those parameters stable. Quality maintenance bridges TPM's equipment focus with quality management's product focus, recognizing that many quality problems originate from equipment variation rather than material or operator issues.

Examples

A quality maintenance analysis linked surface defects to spindle bearing wear. The team established bearing vibration limits that predicted quality degradation, triggering replacement before defects appeared. Scrap rate dropped from 2.3% to 0.3%.

Key Points

- Links equipment conditions to product quality outcomes

- Identifies which equipment parameters affect which quality characteristics

- Establishes maintenance standards that prevent quality degradation

- Bridges TPM's equipment focus with quality management

Common Misconceptions

Quality maintenance is quality control. Quality control inspects output; quality maintenance prevents defects by maintaining equipment conditions. QM asks "what equipment conditions produce this quality?" and maintains those conditions.

All quality problems are equipment problems. Quality maintenance addresses equipment-driven quality issues. Material variation, design issues, and operator techniques also affect quality. Quality maintenance is one pillar, not the complete quality system.