Yellow Belt

Personalize This

Get insights for your role

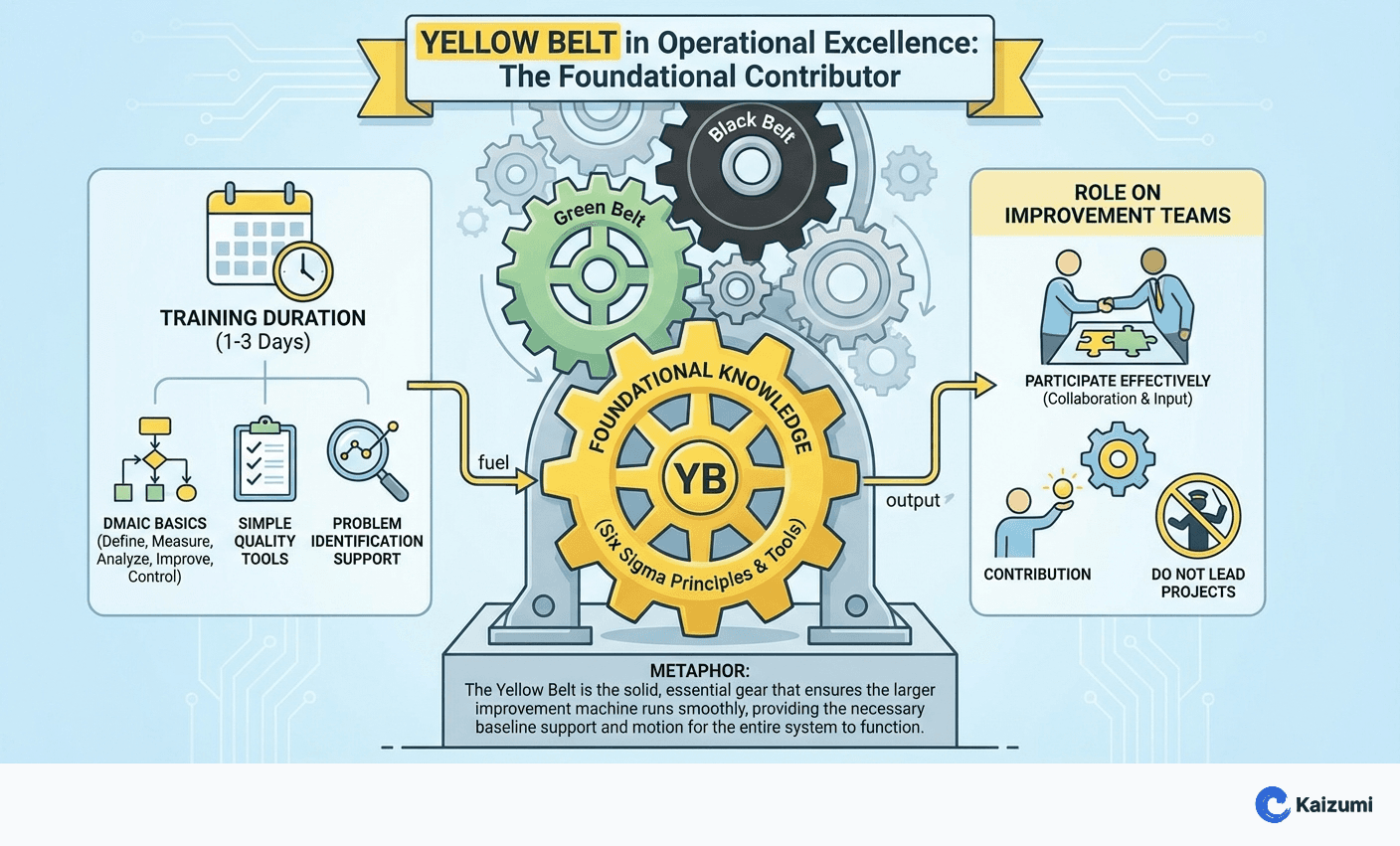

A Yellow Belt has foundational Six Sigma knowledge to participate on project teams and apply basic improvement concepts in daily work.

Definition

A Yellow Belt is an employee with foundational knowledge of Six Sigma principles and tools. Yellow Belt training typically spans one to three days and covers DMAIC basics, simple quality tools, and how to participate effectively on improvement teams. Yellow Belts don't lead projects but contribute as team members—collecting data, participating in brainstorming, and supporting implementation. Many organizations provide Yellow Belt training broadly to create a common improvement language and culture.

Examples

Assembly line operators received Yellow Belt training covering process mapping, data collection, and root cause analysis. When a quality issue arose, they could immediately gather meaningful data and contribute observations to the Green Belt leading the investigation, accelerating problem resolution.

Key Points

- Training typically covers 1-3 days of fundamentals

- Focus is on understanding Six Sigma language and tools, not leading projects

- Yellow Belts contribute to projects as team members and data collectors

- Broad Yellow Belt training creates organizational improvement literacy

Common Misconceptions

Yellow Belt training is unnecessary. Organizations that skip foundational training find project teams struggling with basic concepts and resistant to data-driven decisions. Yellow Belt training creates engaged participants who understand why data matters.

Yellow Belts should lead projects after training. Yellow Belt training provides awareness, not project leadership skills. Attempting to lead DMAIC projects with only Yellow Belt knowledge typically produces superficial results. Green Belt training is the minimum for project leadership.